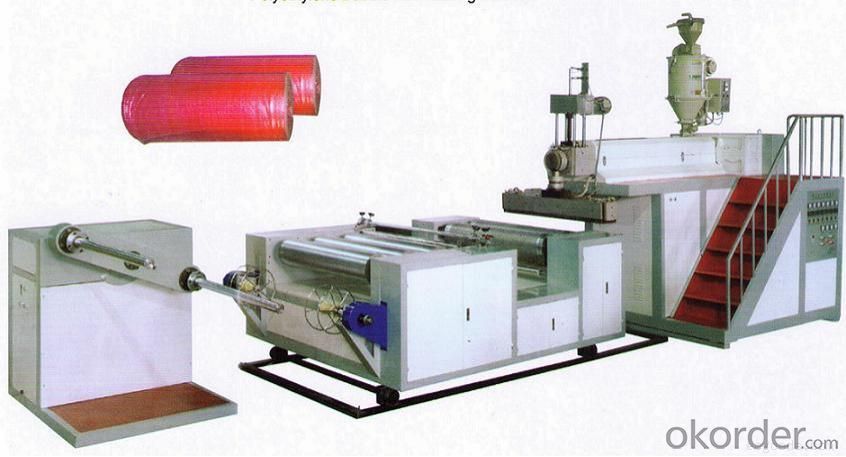

JSM Polyethylene Bubble Film Making Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STRUCTURE FEATURES:

This machine adopts once-through shaping technique, thus has high efficiency and excellent product quality. This machine set has such features as scientific and reasonable structure design, Smooth and reliable running and convenient operation and maintenance.

Polyethylene air-cushion film is a kind of packing materials which has been widely used at present. It not only has good cushioning effect, shock resistance and heat-sealing performance, but also has such advantages as good corrosion resistance and transparency, etc. So it has been widely used for packing, household wares, post parcel, precise instrument, bicycle, polyurethane furniture, etc.

TECHNICAL PARAMETER:

Model | JSM-650 | JSM-1000 | JSM-1200 | JSM-1500 | JSM-2000 |

Screw Diameter | Φ55mm | Φ60mm | Φ65mm | Φ80mm | Φ90mm |

Film Width | 650mm | 1000mm | 1200mm | 1500mm | 2000mm |

Max. Output | 25kg/h | 40kg/h | 50kg/h | 65kg/h | 80kg/h |

Main Motor Power | 11kw | 15kw | 18.5kw | 22kw | 37kw |

Power | 30kw | 48kw | 55kw | 70kw | 105kw |

L/D | 30:1 | 30:1 | 30:1 | 30:1 | 30:1 |

Power Supply | 380/3/4/50 (Volt/Ph/Line/Hz) | ||||

Weight | 3500kg | 4000kg | 4200kg | 4500kg | 7000kg |

Overall Dimension (L*W*H) | 9.0×3.0×2.5m | 9.0×3.0×2.5m | 9.5×3.8×2.5m | 10×4.0×2.6m | 11.5×4.8×4.0m |

FAQ:

Where is your factory located:

Our production base is located in Zhejing Province.

Will your side be responsible for installation, is it for free?

We will be in charge of installation, but you have to pay related fee.

What is the advantage of your company?

Our company is the largest building materials and equipment suppplier in China, second in the world, as a state-owned company, we strictly focus on quality management, our production is under the standard of IS0 9001. for the more, we have experienced logistic team, which is responsible for puntual deilivery and cheapes shipping charge.

- Q:Does anyone know the operating procedures for the cable 65+120 extruder?

- Operating procedures are based on the preparation of equipment instructions, you can increase some of the preparatory work before the boot, the middle is the operation of equipment instructions, and finally must have safe and civilized operation instructions!

- Q:For example, 70 square conductors, the outer diameter is A, out of the insulation, then the line mouth to choose how much, how much plastic cover election? Then the sheath, then how to choose the mold?

- Depending on your specific specifications, if XLPE is insulated, extrusion die with small touch line, set on the use of cable diameter, large core conductor than a few tenths of good, if you like to use 70 square tube extruding mold insulation of the conductor element some is big 1 can be set according to the touch, the tensile ratio calculation,

- Q:What is the adjustment method of China's extrusion machine die?

- The adjusting method of the die is as follows: (data refer to China. Extruder)(1) air to mold: adjust the die before production, adjust the distance between the mold core and the die suite evenly with the naked eye, and then screw the die screws.

- Q:Is the extruder the same as the extruder?

- Extrusion machine, also called extruder, and is mainly used for power line, power cable, coaxial cable, communication cable, transmission cable, BV type civil line, electronic wire, computer wire, building line, data communication cable, RF cable, HDMI cable, cable, all kinds of high temperature silicone Teflon, core line line, network cable, optical fiber, rubber insulated wire cable wire and cable extrusion wire and cable equipment.

- Q:Who knows the structure of the big extrusion machine head (has cooled), smash what structure, model of plastic crusher?

- How big is it? Not too big. I suggest using a 40 or 30 too big block. You have to use a special break knot. There is a kind of broken engineering material. I wonder if you can find it

- Q:Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- They can see it moving.God doesn't need itSometimes you hear, fifth hand material,Cool sounds in the swirling smokeCoagulation together, I have left their land,Yesterday was a similar experience, ha ha

- Q:Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- I am a professional pipe mold, can you say more details?

- Q:when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- I've also encountered (missing a pulse alarm), and finally checked out is a SCR triggered, impassability, you can try

- Q:How many roots are produced in an hour for an PVC tube extruder?

- It depends on the type of your extruder and the specification of the tube you produced

- Q:Why can the plastic extrusion machine extrude the flat bar?

- What's the reason for pulling out the stripes?1, the vacuum is not enough.2, high temperature settings.3, formula lubrication is too much

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

JSM Polyethylene Bubble Film Making Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 20 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords