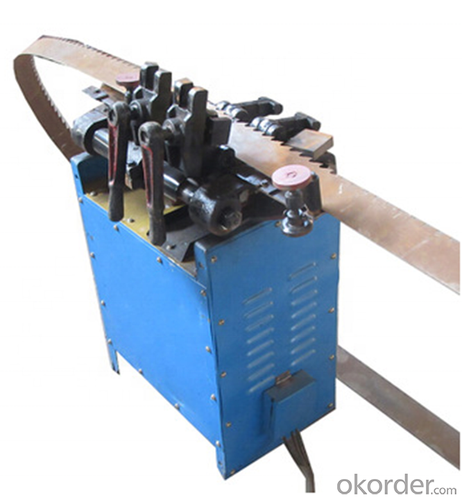

UN6-50 Flash Seal-welding band saw blade butt welding machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of UN6-50 Flash Seal-welding band saw blade butt welding machine

This welder is a special lever pressure type saw blade purpose welding machine,and during welding of saw blades,it needs no weld paste or solder.

It is characterized by an extremely short welding duration and the low energy consumption,and in merely several seconds after being energized,it can surely weld saw blades together.

It is low in cost and the quality of the resulted weld is much superior to that generated by traditional silver soldering or oxygen welding procedures.

2. Parameter of UN6-50 Flash Seal-welding band saw blade butt welding machine

Technical Parameter | UN6-50 | UN6-100 | UN150 |

Welding Saw Blade Width (MM) | 6-50 | 6-125 | 30-150 |

Welding Saw Blade Thickness (MM) | 0.5-1.15 | 0.7-1.25 | 0.7-1.25 |

Voltage | 380V 50 HZ | 380V 50 HZ | 380V 50HZ |

Machine Weight (KG) | 110 | 240 | 308 |

Machine Size(MM) | 650*350*800 | 850*500*1050 | 850*450*1180 |

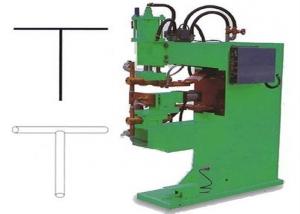

3. Images of UN6-50 Flash Seal-welding band saw blade butt welding machine

4. Packages

Standard export Carton box or plywood box package- Q: To the welder 380 V, 36 volt transformer always burn, what's the matter?

- The butt welding machine is intermittently working and won't burn easily. If burned frequently, it means that the no-load current is too large and it is very hot when not working. The countermeasures are: after burn wound, asked the chef to the primary coil (a primary coil) increase the number of turns of 5%, this will not be burned, but the general master are not willing to give you more laps, though you give more money. They will say "the place is not enough." "not open around ah" and so on the grounds, because more laps rarely burned, so messed up their jobs, cut its way. Not just the transformer, the maintenance of the motor is the case. There is a way to let him to ensure the use of time, such as a month burned once, you let him that two years is not burned, is winding double the fee increase, the general master will agree, control the time they have burned, grasp than you.

- Q: Do welding electrodes need to be used for the welding machine? Will there be smoke and dust in the welding process?

- Butt welding machine is also called impact welding machine, the welding machine voltage is very low, the current is very large, the use of two pieces of metal collision, short circuit, high current welding. Soot is not large, but there is an arc of shallow metal dust.

- Q: Is the spot welding machine good or DC?

- AC welding machine is the wire package step-down transformer using welding rod, this machine, old technology, power consumption, copper consumption.The DC welding machine includes thyristor, inverter (MOS tube, IGBT single tube and IGBT module), and the technology is more and more advanced.The inverter is a new technology that has appeared in the last 10 years, saving more than 35%. Because there is no large transformer, a great deal of copper is saved, and the transformer consumption is also reduced a lot. The disadvantage of DC is that the magnetic deviation blows, and the other is all advantages. Arc stability, weld formation is good, and there is welding rod, general acid welding rod is AC and DC can use, alkaline welding rod recommend DC, cellulose electrode, seems to only dc.

- Q: Bending machines, straightening machines, butt welding machines, straight thread lathes, and cutting machines are the prices of these machines for general engineering use

- Bending machines, straightening machines, butt welding machines, straight thread lathes, and cutting machines are the prices of these machines for general engineering useLow, good quality. Provide for machine tools.

- Q: Consult 1 sets of 100KVA butt welding machines. What is the power? How much is the power consumption per hour?

- A*V is the power (W), if it is three-phase welder, and then *1.4.

- Q: Flash butt welding fixture? What are the advantages and disadvantages of semi-automatic flash butt welding machine and automatic flash butt welding machine? Do you have anyone who knows? Baidu half a day without fruit ah!!

- Yes, I've heard nothing about it

- Q: PPR pipe is not connected to the welding machine

- Right, as upstairs said, with fast access, with rapid elbow and copper quick connect directly, see you want to corner an PPR tube or an PPR straight tube. There are a lot of brands, Rui River, PPR pipe fittings, Jinde, and so on. General hardware building materials stores have sold, the price is not expensive, about more than 20 yuan

- Q: Hello, I am doing wire hardware, I would like to know the line welding machine, welding machine, etc., and wire bending, molding, etc., there are no related exhibitions, thank you!!Just to know if there are any related exhibitions

- Proposed to Miyoshi Street opposite the South Lake Hardware City to inquire about

- Q: What is the approximate power of the UN1-75 flash butt welder?

- 75 refers to the power, multiplied by 1000, power that is 75000 watts

- Q: Preloading time:Pressurization timePreheating timeintervalSlow risewelding currentWelding timeintervalSlow downTemper currentTemper timeMaintenance timeResting timePressurization delayPressurization timeWhat are the implications and setting techniques for these parameters?

- You can supply me with the power of your machine, so that I can help you.

Send your message to us

UN6-50 Flash Seal-welding band saw blade butt welding machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches