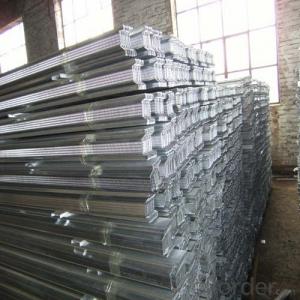

U-Shape Ceiling Profile System

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications and Advantages:

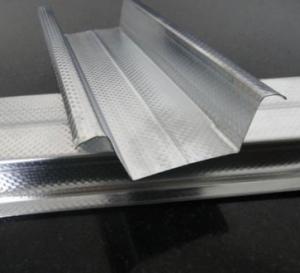

1. Material: Galvanized Steel Sheet

2. Items: Crab connector, U-shape, Wall angles and etc.

3. Size: Standard or customized

4. Use: For steel profile (ceiling and partition systems)

5. Easy and fast for installation, time-saving;

6. Can supply products based on specific requirements;

7. Prompt delivery, high quality, competitive price and complete sets of style;

8. Can supply products based on specific requirements;

- Q: Please give valid certificate, thank you! The

- The keel of the ceiling needs to be re-examined: Detection parameters Keel: size deviation, mechanical properties; Accessories: size deviation, mechanical properties. Keel ceiling project quality acceptance project: Ceiling elevation, size, from the arch and shape should meet the design requirements. Test method: observation; scale inspection. The material, variety, specifications, regiment and color of the facing material should meet the design requirements. When the facing material is a glass plate, use safety glass or take reliable safety measures. Inspection method: observation; check product certificate of competency, performance testing report and admission inspection records. Finishes should be tightly installed. The overlapping width of the facing material and the keel should be greater than two-thirds of the width of the keel. Test method: observation; hand pull check; scale check. Boom, keel material, specifications, installation spacing and connection should meet the design requirements. Metal boom, keel should be surface corrosion treatment; wood keel should be anti-corrosion, fire treatment. Inspection methods: observation; foot check; check product certificate of competency, admission acceptance records and hidden engineering acceptance records.

- Q: What kind of material is better for some kind of ceiling, such as wood keel, light steel keel, or

- After the line with the woodworking board to open about 200mm wide oval frame (upper and lower layers) and then use 200 * 400 (height) of the wood plate around the oval to do the upper and lower layers of the two oval connected inside and then sealed 5mm board plate Hang up to shape out (drawing very good description of the painting really can not say you do not know clearly)

- Q: 38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- 1-1.2mm thick

- Q: Ceiling light steel keel specifications are models which several

- Wall keel main specifications are divided into Q50, Q75, Q100 and Q150. Ceiling keel main specifications are divided into D38, D50 and D60 and so on. According to their cross-sectional shape is divided into U-type, C-type, T-type, H-type, V-type, L-type, CH-type seven, light steel keel mark the order: product name, code, cross-sectional shape of the width, Thickness and standard number. Customers should be based on process and decoration requirements, decided to use the wall keel, ceiling keel and specifications and cross-sectional shape.

- Q: What kind of size of the ceiling?

- 30 * 40

- Q: Ceiling twenty square meters need light steel keel how many roots

- If the height of the room does not exceed 4 meters, usually: the main keel 1.2 meters, vice keel 4 meters (300MM open file), 1 meter pole, gypsum board 1.05 square (5% loss). Accessories too much here to do not introduce. The above calculation method is limited to flat top, if the shape plus 20% -30%

- Q: Ordinary light steel keel gypsum board ceiling budget sets which quota

- Ordinary flattened around with a light bulb, then 120 yuan per square meter Shaped 180 yuan per square meter Below this price you can not make money

- Q: Ceiling light steel keel 50/60 in 60 on behalf of what

- 60 represents the width of the main and vice keel,

- Q: PVC plastic buckle plate ceiling with what keel ah?

- Person for four reasons First, the self-tapping screw did not follow the specifications into or self-tapping nails too tight, resulting in gypsum board surface rupture Second, the gypsum board seams are not closed according to the normal use of gypsum board special tape and indeed good cloth Third, the surface is not putty treatment, the base layer is dirty Fourth, the paint used does not have crack resistance

- Q: For example, the original requirement is 0.9 to 1.0 But actually made a 0.7, Is there any harm?

- Ceiling in the wood keel spacing: 1, light steel keel: keel for the edge of the dragon, the lamp slot position with keel or woodworking board production, there are wood production office to brush fire paint, keel at least 50, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, gypsum Between the board and the board to be reserved for 5-8 mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to be smooth and solid, shaped to be smooth lines; 2, keel: keel at least 3 × 4 or more, spacing 30cm is appropriate, hanging spacing 60-80cm is appropriate, hanging bar is strictly prohibited direct use of wood wedge nail to the top, brush tight fire paint until the keel color can not see the dragon A layer of full-legged rice eucalyptus core after nine on the gypsum board, gypsum board and the board between the people to set aside 5-8mm gap, gypsum board self-tapping screws 1-2mm and do anti-embroidered treatment, to do To the formation of solid, shaped to do smooth lines; 3, aluminum buckle board: strict requirements level, light steel keel bayonet to be aligned, keel spacing of 50 or less, hanging spacing 60-80 cm is appropriate, the board when the hand to light, so as not to press the board, And the contact with the tile is not tight to use the sealant to play tight; 4, aluminum-plastic plate: keel at least 3 × 4 or more, spacing 30 cm is appropriate, hanging spacing 60-80cm is appropriate, brush tight fire paint, keel on a layer of full-legged rice eucalyptus core 9% Adhesive paste aluminum-plastic plate, aluminum-plastic plate between the board to be reserved for 3-4mm gap, prepared to fill other colors play the effect of sub-grid, to be smooth and solid, shaped to do smooth lines, folding The angle can not be broken.

Send your message to us

U-Shape Ceiling Profile System

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords