Tx-5 Polypropylene Non-Woven Geotextile Roll with High-Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Type:

Geotextiles, Nonwoven Geotextile woven Geotextile

Place of Origin:

Shandong, China (Mainland)

Brand Name:

CMAX

Model Number:

CMAX-S001

Geotextile Type:

Non-Woven Geotextiles Woven Geotextiles

Width:

1m-8m

Length:

Customer Requirment

Weight:

100g/m2-1500g/m2

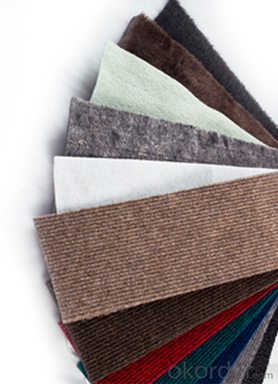

Color:

White, Black, etc

Application:

Water Conservancy

Material:

PP(polypropylene) PET (polyester)

Certificate:

CE/ISO9001

Break Elongation:

25%~100%

Tensile Strength:

from 2.5 KN/m to 25KN/m

Geotextiles

Divider

Protect the integrity of your gabion basket installation with high-quality geotextiles

between your gabion structures and the soil. We supply only the highest quality of both

woven and non-woven geotextiles for gabion installations and other applications.

These geotextile filter fabric materials prevent the migration of fine soils to the spaces

between rock particles. The migration of fine soil into your gabion structure can cause

subsidence problems below or behind the gabion structure in time if not applied correctly

and will stir up problems – especially in sandy soils. Clay soils do not generally

require a geotextile filter fabric as they seldom leach through the basket section. We

recommend using a suitable geotextile where the gabion is in contact with earth, this will

limit any movement of soils through a gabion structure. In soft soil foundations

especially and wherever overlaps or joins are required, we suggest a minimum overlap of

300mm(1 ft).

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Production of 1 square meter 100g geotextile consumption of polyester fiber how many kilograms

- Theoretically is 100g, I am specializing in the production of geotechnical materials, wish smooth

- Q: Can geotextiles be used in wastewater treatment applications?

- Yes, geotextiles can be used in wastewater treatment applications. They are commonly used in filtration systems to separate solids from liquids and provide support for various treatment processes. Geotextiles can enhance the efficiency of wastewater treatment by improving filtration, reducing clogging, and increasing overall system performance.

- Q: What are the factors to consider when designing with geotextiles?

- When designing with geotextiles, there are several factors to consider. Firstly, the type and characteristics of the geotextile itself should be evaluated. This includes considering factors such as the material properties, strength, durability, and permeability of the geotextile. The specific application and the expected loads and stresses that the geotextile will be subjected to also need to be taken into account. Secondly, the site conditions and environmental factors should be considered. This includes assessing the soil type, slope stability, groundwater conditions, and potential for erosion. Understanding the site-specific conditions will help in determining the appropriate geotextile design and installation methods. Thirdly, the desired functions of the geotextile need to be considered. Geotextiles can be used for various purposes such as separation, filtration, reinforcement, drainage, and erosion control. Identifying the primary function(s) of the geotextile will guide the selection of the appropriate geotextile type and design. Additionally, the installation and maintenance requirements should be taken into consideration. Factors such as the availability of suitable equipment, access to the site, and long-term maintenance needs should be evaluated to ensure the successful implementation and performance of the geotextile. Overall, designing with geotextiles requires a comprehensive understanding of the geotextile properties, site conditions, desired functions, and installation requirements to ensure an effective and durable solution.

- Q: Can geotext prevent rooting?

- Geotextile in the form that is just a layer of soft cloth, can not play the role of anti-root prick. Geotextiles in the practical application of which is generally from the protection, reinforcement, the role of filtration. Mainly with other impervious materials used. Anti-root prick material has a special resistance to the root film, geomembrane, both can effectively prevent the root of the root can also wear a good anti-seepage effect. You can describe the details of the situation under the trees, I recommend you choose to choose the root film, geomembrane specifications.

- Q: Are geotextiles suitable for use in geotextile-reinforced soil walls?

- Yes, geotextiles are suitable for use in geotextile-reinforced soil walls. Geotextiles are commonly used to reinforce soil and stabilize slopes or walls. They provide strength and stability to the soil, preventing erosion and improving the overall performance of the structure. Geotextiles also act as a filter, allowing water to pass through while retaining the soil particles. This makes them an ideal choice for geotextile-reinforced soil walls, where the geotextiles help to distribute loads and enhance the structural integrity of the wall.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: Can geotextiles be used in canal lining applications?

- Yes, geotextiles can be used in canal lining applications. Geotextiles are often utilized as a barrier or separator between different soil layers in canal lining to prevent soil erosion and provide stability. They offer excellent filtration properties and can help in the effective drainage of water from the canal. Additionally, geotextiles can also reinforce the canal lining, enhancing its durability and reducing the chances of cracks or damage.

- Q: Geomembrane upstream protective layer with what material? The Why can not you use clay?

- With geotextile to do protective layer, because the geotextile and geomembrane as with acid and alkali, is the characteristics of corrosion, the useful life of more than 50 years can better protect the geomembrane. Clay and its performance is far from the comparison, so the use of geotextile hides to avoid waste Zhuan belly over the sand to make the upper reaches of the protective layer. Inquire about Yinjing Li

- Q: Can geotextiles be used in the protection of embankments?

- Yes, geotextiles can be used in the protection of embankments. Geotextiles are commonly used in civil engineering projects to enhance the stability and performance of embankments. They can help with erosion control, soil reinforcement, and drainage, reducing the risk of slope failures and enhancing the overall durability of the embankment.

- Q: What are the different geotextile durability testing standards?

- There are several geotextile durability testing standards, including the ASTM D4355-17 for durability of geotextiles by accelerated weathering exposure, ASTM D4751-10 for determining the apparent opening size of a geotextile, ASTM D6768-18 for evaluating the effects of heat on geotextiles, and ISO 10319:2015 for determining the resistance of geotextiles to weathering.

Send your message to us

Tx-5 Polypropylene Non-Woven Geotextile Roll with High-Performance

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords