Tubular Fabric Edge-Cutting Winding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Tubular Fabric Edge-Cutting Winding Machine

Packaging Details: Wooden case/ pallet or as your request.

Delivery Detail: 7-15 Days after confirm the order.

Specifications of Tubular Fabric Edge-Cutting Winding Machine

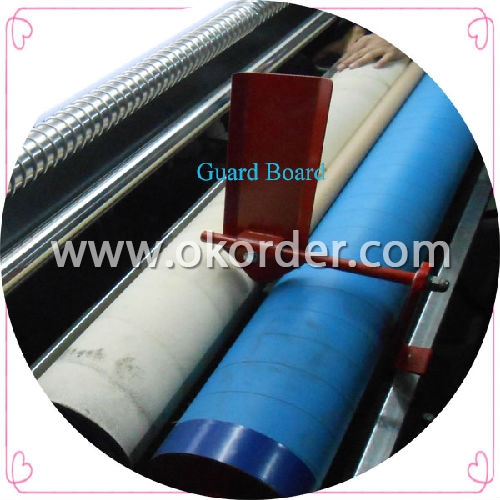

Edge-Cutting Winding Machine

1.Hydraulic edge-aligning system

2.12 years expreience

3.Used tubular knitted fabric

4.CE

Usage of Tubular Fabric Edge-Cutting Winding Machine

Tubular Fabric Edge-Cutting Winding Machine is specially designed to slit, inspect and rewind tubular fabrics and it is suitable for knitting plant.

- Q: What is the turntable printing machine?

- Due to the printing of the model less and so on, resulting in can not print multi-color mortar

- Q: What is sizing?

- The addition of these chemical auxiliaries makes the slurry prone to foam

- Q: What is oval printing machine?

- Printing Taiwan version is a separate block, rather than the artificial silk screen treadmill as tens of meters long continuous. Can be printed on the printing table on the printing table, you can also print clothing pieces (can not print the whole volume of cloth

- Q: What are the classification and characteristics of the fabric?

- 3. Wool fabric characteristics: firm wear, quality, warm, flexible, anti-wrinkle, easy to fade.

- Q: Textile cad and mechanical cad the same?

- Including: clothing design CAD with four modules: playing version of grading, nesting, test clothing, drawing output

- Q: What is rotary screen printing?

- At the time of printing, the paste is fed into the net and stored at the bottom of the net

- Q: What is finishing finishing after finishing?

- After heat-setting fabric, in addition to improving the dimensional stability, the other performance also has a corresponding change, such as wet rebound performance and pilling performance are improved, feel more stiff;

- Q: What is the dyed craft table?

- 2. Fabric specifications: 32 * 32 +40 D (cotton stretch) latitude and longitude: 136 * 70 Width: 48/50 "150 * 70D +40 D (Nylon stretch cloth) latitude and longitude: 120 * 80 Width: 48 / 50 "40 + 150D * 75D + 40D (polyester and nylon cotton elastic cloth) latitude and longitude 138 * 76 Width: 48/50" 3. elastic yarn quality requirements

- Q: What are the characteristics of memory silk fabric?

- Excellent antibacterial, mildew and skin care of the conservation, so that your skin season like spring;

- Q: What is flat screen printing?

- At the time of printing, the stamped version of the fabric, the flower version of the color paste, with a scraper reciprocating scraping pressure, so that the color through the pattern to reach the fabric surface

1. Manufacturer Overview

| Location | Changshu, China |

| Year Established | 2008 |

| Annual Output Value | 15Setyear |

| Main Markets | Mid East; Eastern Europe; Westen Europen |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 8000 square meters |

| No. of Production Lines | Above2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Tubular Fabric Edge-Cutting Winding Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Sets Per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches