Automatic Large Package Yarn Cone Textile Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application:

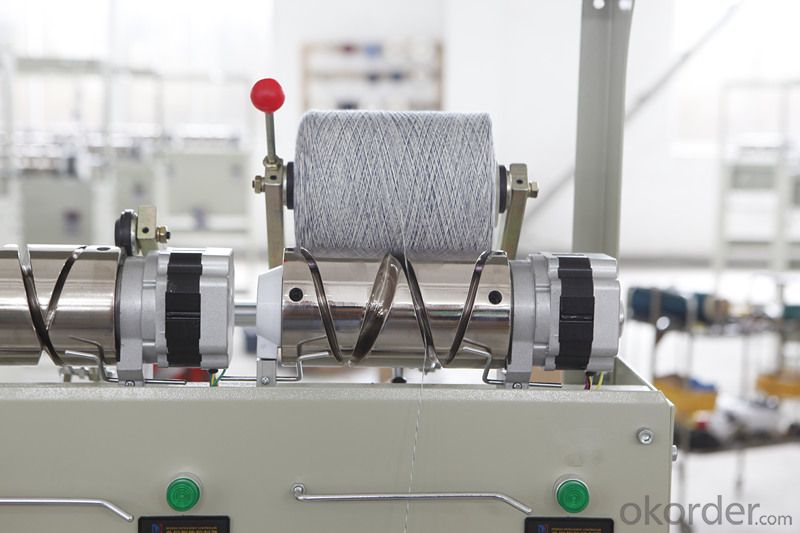

Automatic Large Package Yarn Cone Textile Winder is suitable for winding yarns on cones with even density and soft package before dyeing.

Main features:

Automatic Large Package Yarn Cone Textile Winder

1. Vertical yarn path design, no inflection point, yarn friction is small, less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

8. There is tube conveyor on the machine, it can convey tubes and packing automatically. With it, you can not only save labor, but also keep the production site clean.

9. Our adjustable block yarn sheet metal can prevent the yarn be a mass.

Product pictures of Automatic Large Package Yarn Cone Textile Winder:

Delivery Pictures:

Specification:

Automatic Large Package Yarn Cone Textile Winder

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm, |

| Package bobbin | Cylindrical or conical of 3°30’ |

| package diameter | Up toφ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Package weight | Up to10kg |

FAQ of Automatic Large Package Yarn Cone Textile Winder:

· Q:What is the machine used for?

A: Automatic Large Package Yarn Cone Textile Winder is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is the turntable printing machine?

- The But because of its limited labor, India need to print one color drying one color mortar and in the dark cloth on the need to hit the white heat of the ink

- Q: What is the digital printing machine?

- Through the computer printing color separation system (CAD) editing processing

- Q: What are the applications of silicone oil?

- The use of special materials, but also for the various sectors of the national economy, its application has been extended to: construction, electrical and electronic, textile, automotive, machinery, leather

- Q: Is the development of wool in Australia developed?

- The Australian Wool Board, the Australian Textile Fibers Processing Enterprise Association and the Australian Wool Marking Company are responsible for the management, guidance and advisory services on the promotion of the production, sale and marketing of wool-containing raw materials.

- Q: Textile cad and mechanical cad the same?

- Including: clothing design CAD with four modules: playing version of grading, nesting, test clothing, drawing output

- Q: What is the difference between a dyed fabric and a burnt fabric?

- After washing, that is showing only the translucent flower of polyester. In the printed acid paste, but also can be printed on white paint as part of the blossom brush;

- Q: What is the difference between embossing and etching?

- Process is relatively complex, is the textile dyeing and finishing used in a very common way of finishing

- Q: What is flat screen printing?

- Flower pattern on the pattern can be through the color paste, no pattern at the polymer membrane layer closed mesh.

- Q: Long fiber textile finishing, including what?

- The anti-ultraviolet finishing process of fiber or textile is related to the characteristics of the finishing agent and the end use of the product. Commonly used process methods are:

- Q: How to identify silk and rayon by hand?

- Silk feel soft, flexible, gently when the sound of silk, there is cool feeling; and rayon feel more rough, not wet cold feeling.

Send your message to us

Automatic Large Package Yarn Cone Textile Winder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords