TPO Waterproof Membrane Professional Supplier for Thickness 1.2mm 1.5mm 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

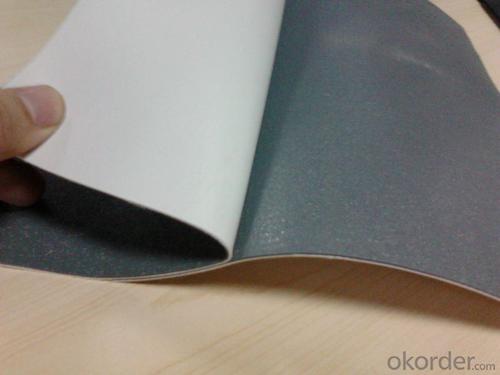

TPO Waterproof Membrane

1. Introduction

TPO (Thermoplastic Polyolefin) waterproof membrane is typically based on polypropylene and EP (ethylene-propylene) rubber. TPO mainly contains carbon atoms and hydrogen atoms and does not contain any plasticizers and chlorine elements. It is a beautiful, long-lived environment-friendly product. TPO membranes are installed mechanically-attached, fully-adhered or ballasted.

2. Features

l It’s easy to install with good system integrity, few accessories.

l Excellent tensile strength, tearing resistance and penetration resistance performance..

l Hot-air welding. The peel strength of joint is high. Fast welding speed.

l Environment friendly, 100% recycled, without chlorine.

l Durable hot welding performance and easy to repair.

l Smooth surface, no fading and pollution.

Systems

Thanks to a variety of installation systems, the UltraPly TPO Roofing System can be used on the most challenging rooftops, for both renovation and new built applications.Product

The UltraPly TPO Roofing System consists of a light colored, environmentally friendly UltraPly TPO roofing membrane and a complete range of accessories. This combination offers a unique combination of features & benefits.Technical Information

We provides to distributors, contractors, specifiers and building owners a comprehensive range of technical documents, such as specifications, data sheets, type approvals and detail drawings.Installation

The installation guidelines help the contractor installing the UltraPly TPO Roofing System in accordance with Firestone's requirements.Training

The UltraPly TPO Roofing System is exclusively installed by approved roofing contractors that have successfully completed a training program in one of training centers.Project References TPO

Since the installation of the first UltraPly TPO roofs in the early nineties, hundreds of thousands of square meters of UltraPly TPO membranes have been installed worldwide. The project portfolio includes a selection of major projects.

3. Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Internally reinforced with fabric, With fabric backing |

Color | White grey |

4. Applications

l Roof construction & steel structure of both industrial and civil engineering

l Underground engineering, such as subways, tunnels, air Raid shelter, etc.

l Sewage treatment, dam, reservoir and basement, grain storehouse, etc.

5. Classification

H- Homogeneous TPO membrane

L- TPO membrane with fabric backing

P- TPO membrane internally reinforced with fabric

6. Technical Data Sheet

TPO Waterproof Membrane | Standard: GB27789-2011 | |||||||

NO. | Item | Unit | Value | |||||

H | L | P | ||||||

1 | Resin Thickness on Middle Mesh ≥ | mm | - | - | 0.4 | |||

2 | Tensile Properties | Max. Strength ≥ | N/cm | - | 200 | 250 | ||

Tensile Strength ≥ | Mpa | 12.0 | - | - | ||||

Elongation at Max. Strength ≥ | - | - | 15 | |||||

% | 500 | 250 | - | |||||

3 | Dimensional Stability after Heat Treatment ≤ | % | 2.0 | 1.0 | 0.5 | |||

4 | Foldability at Low Temperature | -40℃ No cracks | ||||||

5 | Watertightness | 0.3Mpa, 2h No penetration | ||||||

6 | Resistance to Impact | 0.5kg*m, No penetration | ||||||

7 | Resistance to Static Loading | - | - | 20kgs No penetration | ||||

8 | Joint Peel Strength≥ | N/mm | 4.0 or membrane broken | 3.0 | ||||

9 | Right Angle Tearing Strength≥ | N/mm | 60 | - | - | |||

10 | N/mm | - | 250 | 450 | ||||

11 | Water Absorption (70℃, 168h) ≤ | % | 4.0 | 3.0 | ||||

12 | Aging in Hot Weather (115℃) | Time | 672h | |||||

Appearance | No bubbles, cracks, layering, sticky, hole | |||||||

Max. Tensile Retention Rate ≥ | % | - | 90 | |||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

13 | Chemical resistance

| Appearance | No bubbles, cracks, layering, sticky, hole | |||||

Max. Tensile Retention Rate ≥ | % | - | 90 | 90 | ||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

14 | Artificial aging | Time | 1500h | |||||

Appearance | No bubbles, cracks, layering, sticky, hole | |||||||

Max. Tensile Retention Rate ≥ | % | - | 90 | 90 | ||||

Tensile Strength Retention Rate ≥ | % | 90 | - | - | ||||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 90 | ||||

Breaking elongation Retention rate | % | 90 | 90 | - | ||||

Low Temperature Flexibility | -40℃ No cracks | |||||||

Remarks: l Resistance to static load is for TPO membranes used on roofing l The time of artificial aging of single-ply roofing membrane is 2500h. | ||||||||

Images of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Are waterproofing membranes suitable for residential basements?

- Yes, waterproofing membranes are suitable for residential basements. These membranes are designed to prevent water infiltration and protect the basement against moisture damage. They create a barrier that keeps water out, helping to keep the basement dry and free from water-related issues like mold and water damage.

- Q: Is a waterproofing membrane resistant to cracking or shrinking?

- Yes, a waterproofing membrane is typically resistant to cracking and shrinking. The purpose of a waterproofing membrane is to create a barrier that prevents water from penetrating through surfaces, such as roofs, walls, or foundations. To achieve this, these membranes are usually made from flexible and durable materials, such as modified bitumen, PVC, EPDM, or polyurethane. These materials have inherent properties that allow them to withstand various environmental conditions, including temperature fluctuations, UV radiation, and physical stresses. This resilience ensures that the waterproofing membrane remains intact and stable, even when exposed to challenging conditions. Furthermore, waterproofing membranes are engineered to be highly resistant to cracking and shrinking. They are designed to accommodate movements and structural changes that may occur in the building or substrate over time. This flexibility helps to prevent the membrane from cracking or tearing, even if there are minor shifts or settling in the structure. Moreover, waterproofing membranes undergo rigorous testing and quality control measures during their manufacturing process to ensure their durability and resistance to cracking and shrinking. These tests simulate real-world conditions, including temperature changes, elongation, and compression, to verify the membrane's performance and longevity. However, it is important to note that the quality and performance of a waterproofing membrane can vary depending on the specific product and manufacturer. It is crucial to choose a reliable and reputable brand and ensure proper installation and maintenance to maximize the membrane's resistance to cracking or shrinking.

- Q: Are waterproofing membranes suitable for underground parking garages?

- Underground parking garages necessitate waterproofing membranes due to their constant exposure to groundwater and moisture. These factors can result in water infiltration and structural damage. Waterproofing membranes offer an effective solution to prevent water penetration and safeguard the concrete structure from deterioration. The purpose of waterproofing membranes is to establish a barrier against water and moisture, effectively barring their entry into the garage. These membranes are commonly applied to the parking garage's exterior walls, foundation, and floor slab. They are crafted from durable materials like modified bitumen, polyurethane, or rubberized asphalt, capable of withstanding the harsh conditions of underground environments. By incorporating waterproofing membranes into underground parking garages, the likelihood of water damage, such as concrete cracking, reinforcement steel corrosion, and mold growth, is significantly reduced. The membranes serve as a protective layer, guaranteeing the longevity and structural integrity of the parking garage. Moreover, waterproofing membranes can also aid in minimizing vapor transmission, which may trigger condensation and humidity problems within the parking garage. This is especially crucial for underground parking garages located in regions with high water tables or susceptible to heavy rainfall. All in all, waterproofing membranes are an indispensable aspect of constructing or renovating underground parking garages. They offer a dependable and enduring solution to shield the structure from water infiltration, ensuring the safety and durability of the parking facility.

- Q: Can a waterproofing membrane be used for residential buildings or homes?

- Residential buildings or homes can indeed benefit from the use of a waterproofing membrane. Construction commonly relies on waterproofing membranes to safeguard against water infiltration, shielding both the structure and interior from moisture-induced harm. These versatile membranes find application in diverse areas like basements, roofs, foundations, and bathrooms, among others. By effectively blocking water, these membranes effectively thwart leaks, mold proliferation, and deterioration of building materials. Consequently, employing a waterproofing membrane proves highly efficacious in safeguarding the longevity and durability of residential buildings or homes.

- Q: Can waterproofing membranes be used on swimming pool decks?

- Swimming pool decks can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to act as a barrier against water infiltration, making them an excellent solution for areas that are constantly exposed to water, such as swimming pool decks. By applying a waterproofing membrane to the surface of the deck, it effectively prevents any water from seeping through and causing harm to the underlying structure. Moreover, waterproofing membranes also offer protection against chemicals, UV rays, and general wear and tear, which are commonly encountered in swimming pool environments. All in all, incorporating waterproofing membranes on swimming pool decks can extend their lifespan, decrease maintenance expenses, and elevate the overall safety and appearance of the space.

- Q: The difference between waterproof linoleum and waterproofing membrane

- `Linoleum is a kind of waterproofing membrane! Belong to subordinate relationship. Felt is made of animal hair or plant fiber made of carpets or thick paper impregnated asphalt after the building materials, toughness, impermeable, used to do the roof, basement walls, foundations such as waterproof, moisture-proof layer. Also called oil felt. Approximately 2000 years ago, the most commonly used building waterproof material, has now been included in the scope of national banned building materials. At present, the construction of waterproofing membrane is large "elastomer modified asphalt waterproofing membrane" - the implementation of standards for the GB 18242-2008.

- Q: Can a waterproofing membrane be used in crawlspaces or basements?

- Yes, a waterproofing membrane can be used in crawlspaces or basements. In fact, it is highly recommended to use waterproofing membranes in these areas to prevent moisture infiltration and water damage. Crawlspaces and basements are prone to water seepage and high humidity levels, which can lead to mold growth, structural issues, and damage to stored items. A waterproofing membrane acts as a barrier against water intrusion by effectively sealing the foundation walls and floor. It creates a watertight seal that prevents water from seeping into the space, keeping it dry and protected. Additionally, waterproofing membranes also help to control moisture levels by reducing condensation and humidity, thereby creating a healthier and more comfortable environment. Overall, using a waterproofing membrane in crawlspaces or basements is an essential measure to ensure the longevity and integrity of the structure and to safeguard against potential water-related problems.

- Q: How does a waterproofing membrane handle joint or crack movements?

- A waterproofing membrane is designed to handle joint or crack movements by being flexible and accommodating the expansion and contraction of the underlying structure. It can stretch and move with the joints or cracks, ensuring that it remains intact and provides a continuous barrier against water penetration.

- Q: How does a waterproofing membrane handle soil movement and settlement?

- Soil movement and settlement are effectively managed by a waterproofing membrane through various mechanisms. Initially, it functions as a barrier between the structure and the soil, thereby preventing water intrusion and minimizing the impact of soil movement on the building. To address soil movement, the membrane exhibits flexibility and elasticity. This enables it to adapt to minor soil shifts and settlements without experiencing cracks or tears. By flexing in conjunction with the movements, the membrane preserves its integrity and sustains its waterproof seal. Moreover, the waterproofing membrane frequently incorporates reinforcements like polyester or fiberglass to enhance its strength and resistance to soil movement. These reinforcements assist in distributing the stress caused by soil settlement across a larger area, thereby reducing the risk of membrane damage. Another crucial consideration is the proper installation and anchoring of the membrane to the structure. This ensures that it remains securely in place even when the surrounding soil moves. Consequently, the membrane avoids shifting or detaching, which may compromise its effectiveness and result in water infiltration. Furthermore, some waterproofing membranes possess self-healing properties. This means that if the membrane sustains punctures or damage due to soil movement, it can automatically seal the breach to prevent water from entering. This self-repairing capability provides an additional layer of protection against damage induced by soil. Overall, a correctly installed and well-maintained waterproofing membrane is specifically designed to withstand soil movement and settlement. Its flexible nature, reinforcements, secure anchoring, and potential self-healing ability enable it to effectively manage these challenges and maintain its waterproofing capabilities over an extended period of time.

- Q: Does a waterproofing membrane require any specific primers or bonding agents for installation?

- Yes, a waterproofing membrane typically requires specific primers or bonding agents for proper installation. These primers or bonding agents are necessary to ensure proper adhesion and create a strong bond between the membrane and the substrate, enhancing the effectiveness and longevity of the waterproofing system.

Send your message to us

TPO Waterproof Membrane Professional Supplier for Thickness 1.2mm 1.5mm 2mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords