Tongue and Groove PVC Ceiling - Qualified Decorative Ceiling Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

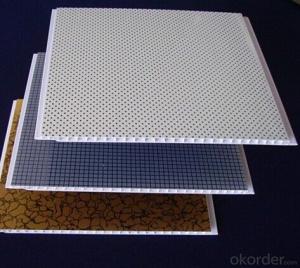

Different types of PVC Panel we are producing:

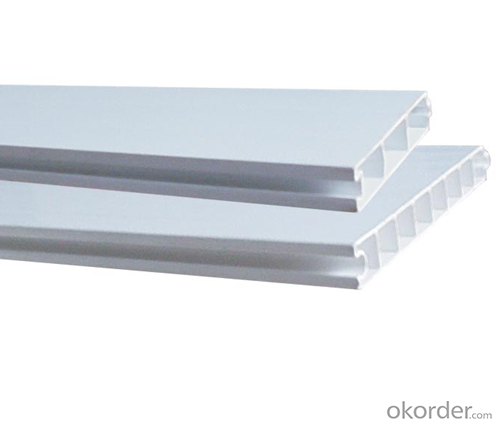

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

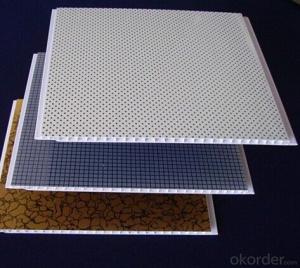

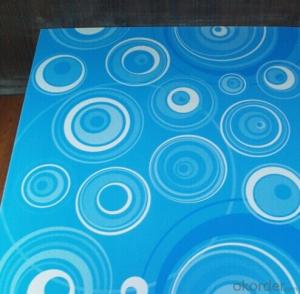

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

Any other specifications are also available here.

The hottest type/specs of the PVC panel: | |||||||||

Luck PVC | PVC CONTENT | Width | Thickness | Length | N.W. | Packing | Loading in a 40'HQ | ||

mm | mm | M | Kg/Sqm | packages | amount/Sqm | ||||

1 | 35%-75% | 200 | 5 | 5.95 | 1.7 | 10 pcs/PE film package | 1142 | 13589.8 | |

2 | 6 | 5.95 | 1.9 | 900 | 10710 | ||||

3 | 7.5 groove | 5.95 | 2.1 | 745 | 8866 | ||||

4 | 8 | 5.95 | 2 | 714 | 8496.6 | ||||

5 | 250 | 4 | 5.95 | 1.5 | 1070 | 15916 | |||

6 | 4.5 | 5.95 | 1.65 | 941 | 13997 | ||||

7 | 7.5 | 5.95 | 2.2 | 591 | 8791 | ||||

8 | 11 | 5.95 | 3.9 | 416 | 6188 | ||||

9 | 300 | 9 | 5.95 | 2.5 | 429 | 7658 | |||

10 | 595/600 | 7 | 0.595 | 2.9 | 20pcs/carton | 1160 | 8213 | ||

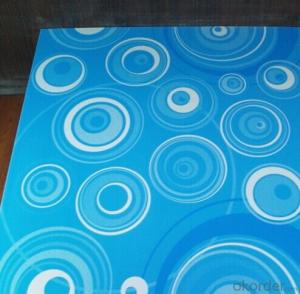

Hundreds of patterns & colors are provided. New patterns are adding ceaselessly, which can keep you on the front of the market

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

Quality Test:

No. | Test Items | Technical Requirements | Detection Result | Single Judge | |

1 | Appearance | Fulfill | Qualified | ||

2 | Flexibility mm/m | <1.5mm/m | 0.48 | Qualified | |

3 | Thickness mm | Faceplate | >0.4 | 0.4 | Qualified |

Base plate | >0.3 | 0.32 | |||

4 | Heating Rate % | <6.0 | 0.6 | Qualified | |

5 | Heated State | No bubble, craze or spot | Fulfill | Qualified | |

6 | Resistance of acetone | No defects | Fulfill | Qualified | |

7 | Dart drop impact | 0.25kg/0.5m,10 times, Pass when keep unbroken above 6 times | pass | Qualified | |

8 | Size Variation in High/Low Temperature | ±0.6% | -0.16 | Qualified | |

9 | Nail resistance | no visible cracks | Indehiscent | Qualified | |

PVC Panel Production Process:

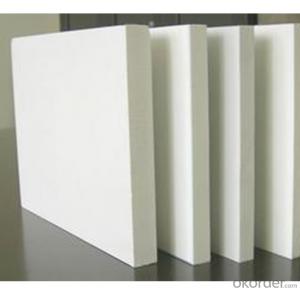

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

Welcome to visit our factory, welcome all interested parties to establish long terms business relationship with us under the mutual benefit and kindly friendship.

- Q: Members XDJM: I work for reasons, a set of home hair blank room idle, recently wanted to simply rent out the rent. A friend said that the floor can be used home PVC floor shop, but we do not understand these things, please help my friends to answer my question, thank you: 1, the thickness of the general requirements of home PVC floor is how much? Requirements can not be easily trampled, hit rotten. 2, PVC floor of the construction conditions is what? Molding room floor can be used directly? 3, my home or the developer of the floor when the developer, the cement is not particularly flat (there are more holes, as if there is no cement road level), with what 4, some people say to brush plastic, need not? Hope that these or their own use of the reply, I only 30 points, all the reward

- You said the ground is not cement road level, there are a lot of holes, I do not know you are not the ground is the sand from the like, if there is a sand from the proposed you do not do cement self-leveling so that the quality of your floor There is no guarantee that the ground is not cement road Ping suggested that you do not do cement self-leveling and do not say how the effect of the cost is too high, the cement self-leveling to find someone to do the price of 15-25 yuan per square meter, and cement self-leveling Each can only do 2-4MM meters, that is to say that you want to make a good effect at least have to do 2 to 3 times, so the cost is too high, I do many years of PVC flooring, it is recommended that you shop The ground before the first to find a good way to find the mud on the ground so that you will be less to a lot of cost and the effect of the bottom out of the floor will be much better

- Q: Wood-plastic board, PVC board, science and technology What is the difference between wood?

- Wood-plastic board is made of wood fiber mixed polymer plastic after extrusion molding, is an environmentally friendly material, its weather resistance is very good, generally used for outdoor decoration. Pvc board is made of pvc material of a material, it is light weight, have a certain strength, but the weather resistance of acid and alkali difference for product packaging and interior decoration. Science and technology wood is made of artificial veneer made of decorative panels, generally with no color, pattern and other natural decorative panels can not achieve the decorative effect, but its pattern rigid, color frivolous no less than the natural decorative panel texture and decorative grade.

- Q: PVC board, ABS board, KT board What is the difference between ~ ~ What are the purposes?

- PP Polypropylene PVC PVC EPS polystyrene ABS acrylonitrile / butadiene / styrene copolymer PC Polycarbonate PE polyethylene KT board is a light decorative plate, the actual is the two sides affixed with smooth paper foam board, generally used for display panels or as a temporary structure of the partition. KT board can be used for display board production, screen printing, etc., with KT board produced by the beautiful display panels, convenient and light, affordable. (But according to multi-feedback: KT board like a bubble, with a long time will be variant, the proposed use of organic board) KT board color: red, white, yellow, green, gray, blue, black. Two kinds of KD board: one is "enhanced anti-foaming KD board", flatness is good, hardness is strong. Applicable to advertising display, especially for large-scale pictorial inkjet produced a variety of board, he is the best cold plate KD plate. The second is the "economic anti-blister KD board", mainly for the back of the frame, screen printing and silk screen after the POP advertising production. It is the best KD plate to bite the market.

- Q: What is the treatment before the color, what kind of paint or paint to color? Satisfied with points

- Pvc board color or pattern can be screen printing.

- Q: What is the difference between pvc plastic flooring and composite flooring? The

- Many different, composite floor can not touch the water, PVC flooring used to fish no problem, this is the biggest difference. PVC floor is not deformed, no telescopic

- Q: I want to use 3MM cardboard or PVC board rolled into a curved thing I use PVC or good paper is good? What cut how to cut? How to make it rolled into the arc and then how to shape? Want to add something on it to paste it? Seek experts to help urgent acridine! The most important thing is how to make it rolled into arc and then how to shape?

- Do not know the arc I understand is not what you said arc Oh

- Q: In a thickness of 2.3mm on the board out of the hole 20, the die value of 20.2, the knife has a polished, punch 20, punch out of the hole often crack, and even bubble-like, clearly see the original surface separation Will this question how to solve it, Punching out of the wafer but also pressure back to the product, in order to smooth, I die in the die where the small chamfer, the problem will not appear on this?

- Tighten the periphery

- Q: Aluminum buckle plate and PVC gusset which is better

- Aluminum Clamps: The aluminum gusset plate is a decorative material suitable for use in kitchen and toilet ceiling applications. At present, the aluminum plate brand has become a home improvement throughout the project one of the indispensable materials. People tend to aluminum slab as metaphor: "kitchen and toilet hat" is because he is the kitchen and bathroom with better protection and beautification of the decorative effect! Aluminum buckle board advantages: 1, has a very good corrosion resistance, to resist a variety of fumes, humid environment, anti-ultraviolet. 2, environmental protection, non-toxic and tasteless, anti-static, no dust, easy to wash, high hardness, fire, non-stick stains. 3, low cost, longer life, and not easy to sink, discoloration deformation. 4, high grade, with tiles, bathroom, kitchen cabinets easy to form a unified style. Aluminum slab plate defects 1, aluminum plate flatness as plastic gusset plate, the installation of more complex steel gusset plate, installation requirements, flatness is poor, patchwork as plastic. 2, aluminum buckle board type, style, no steel and more, aluminum slab mainly to metal as raw material, so the price is higher. 3, aluminum slab plate quality difference, aluminum slab board is also divided into three levels: the first type of aluminum alloy plate, aluminum and manganese alloy plate, aluminum-magnesium alloy plate. The aluminum-magnesium alloy plate has the strongest oxidation resistance.

- Q: Why does PVC flooring be the most suitable for summer use?

- From the comfort point of view: First PVC flooring material is soft, comfortable foot feeling, unlike tiles, marble floor material is very hard. PVC floor structure of precision, soft foam buffer layer can reduce the footsteps and body of the floor of the force, the floor itself also has a comfortable rebound and shock absorption.

- Q: PC board PV board PVC board PPV board distinction and use

- Pvc board generally used with the bathroom and kitchen, the other two I am not very clear. But home improvement using PVC board more.

Send your message to us

Tongue and Groove PVC Ceiling - Qualified Decorative Ceiling Hot Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords