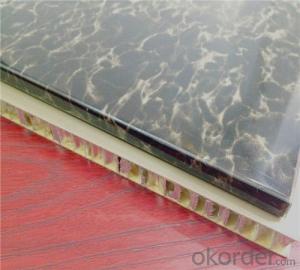

TOBOND wall cladding alucobond/alucobond price/acp price/aluminium composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND PVDF plus Aluminium Composite Panel is special metal surface wall cladding material, compounded with superior aluminum and LDPE Plastic.

Comparing to traditional metal panel, TOBOND ACP is with prime performance of economic efficiency, environment friendly and flexible installation.

ADVANTAGES OF TOBOND ACP

High strength, easy maintenance, 20 years not color fade.

Easy fabrication and installation.

Good Impact Resistance.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

Various color and size for option.

TOBOND ACP Application

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

STANDARD SIZE OF ACP

Series | Coating | Usage | Panel Thickness | Panel Size(mm) |

PVDF Plus Outdoor Panel | PVDF | Exterior Wall Cladding | 4mm /3mm | 1220*2440 1220*2900 |

Indoor panel | Polyester | Interior Decoration/ Advertisement board | ||

Fireproof panel | PVDF/Polyester | Exterior Wall Cladding/Interior Decoration | ||

Special Size For Option | 6mm/5mm | 1250*2900 1500*2900 1500*5800 | ||

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Notching; if notching with notching equipment or gong equipment, using milling cutter with half round head≥90 degree. When notching, pls leave 0.2—0.3mm thickness plastic core materials bending with aluminium sheet to increase intension and tenacity, otherwise aluminium sheet may rupture or coating crack.

Bending: forcing equably when bending, molding one-off, do not bend again and again, or Aluminium panel may rupture.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Batch: same color panel from different batches may have chromatic aberration, contrast process of chromatic aberration should be added if selling or using panels with different batches panels. Panels can be placed on a plane only there may be visual chromatic aberration.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

Cleaning: clear the panel with water, scours or alcohol over98% with soft sponge. Do not use Chemical Solvents.

- Q:Kitchen ceiling with aluminum or aluminum plate is good? Which brand in Jinan, the higher cost?

- With aluminum plate

- Q:Kitchen and aluminum plate or aluminum plate? What is the difference between the integrated ceiling and the two of them? These three kinds of price?

- Certainly with aluminum buckle plate, because his life is relatively long, aluminum-plastic plate, with a 3.5 years to die, the effect is obvious.

- Q:Today, just started to do LED electronic light box, with aluminum-plastic plate openings, plug lights, even lights, street controller, that is done well. Ready to power, check with multimeter, find! shock! The Aluminum-plastic plate side is aluminum foil, conductive! The The 1 how to do? The The LED electronic light box, not using aluminum plate to do it? The

- With plywood, fibreboard also line (also useful iron plate, aluminum plate). But no matter what board, wires, devices, should not touch the board, should be insulated, otherwise, the rain board will be wet, but also conductive.

- Q:I was ordered to OKorder-made aluminum-plastic plate production, long-term Gong Geng in the capital, because the market "hair with" here, find eye

- East building materials are, a lot of!

- Q:The required materials and prices together to make it clear, gray often thank you!

- Materials required: aluminum-plastic panels, angle aluminum, angle code, foam sticks, sealants, self-tapping screws,

- Q:On the report of the project price per square meter engineering requirements is to use 50 * 5 angle iron keel with 4mmA grade aluminum-plastic plate dry hanging

- Skeleton production and installation of aluminum-plastic composite board for the plastic layer are pressed up and down a layer of aluminum sheet, and then in the aluminum plate surface by roller coated with fluorinated vinyl resin, made by baking, aluminum plate using mechanical milling, And leave a 0.3mm thick core material, so as not to hurt the inner surface of the panel. After the cut, fold, strengthen the ribs of the security system. Install the finished parts after installation

- Q:Aluminum-plastic board white, 1500 * 3000 how a small spot?

- What is the amount of this product is a small amount of product? How thick the product, aluminum plate thickness, surface paint requirements?

- Q:Roof by the wood core board base, do the slope; paste the ordinary aluminum-plastic plate, leaving 0.4cm seam, sealed with structural adhesive, after a winter, structural plastic cracks, causing multiple water leakage, some time ago to make up the seal Glue, the problem is not completely resolved. Will you prawn: If you do a waterproof above, how should construction treatment?

- Install the aluminum plate directly on the keel.

- Q:How to identify the quality of aluminum-plastic plate?

- And then cut a piece of the sample, boiled in boiling water for ten minutes, and then come out to put the refrigerator in the frozen one or two hours, if there is time to repeat more than a few times, and then hand or tools to expose the two sides of the aluminum, Opened the description of the quality is relatively poor, if it is not easy to open that excellent quality, which mainly depends on the temperature of hot and cold on the impact of aluminum panels.

- Q:Is there a good separation,

- Ethanol acetone heat treatment, stripping.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

TOBOND wall cladding alucobond/alucobond price/acp price/aluminium composite panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords