alucobond cost per m2

alucobond cost per m2 Related Searches

Acp Alucobond Alucobond Interior Harga Geomembrane Per M2 Plywood Cost Per Square Meter Plywood Per Square Foot Price Cost Of Plywood Per Square Metre Precio De Geomembrana Por M2 Skirting Board Cost Per Meter Geomembrane Cost Per Square Foot Cost Of 1 2 Inch Plywood Alcoa Aluminum Stock Price Cost Of Awnings For Decks Aluminum Wire Price Cost Of Drywall Per Sheet Api2 Coal Price Coking Coal Price Per Tonne Cost Of Cement Board Waterproof Plywood Cost Coal Api2 Price Polyurethane Insulation Board Price Cost Of Plywood Price Of Aircon Gypsum Board Price Per Sheet Anthracite Coal Prices Per Ton Price For Air Conditioner Cost Of Mdf Per Square Metre Lawn Aeration Cost Cost Of Electrical Wire Per Foot Coal Price Per Metric Ton Metallurgical Coal Price Per Tonalucobond cost per m2 Supplier & Manufacturer from China

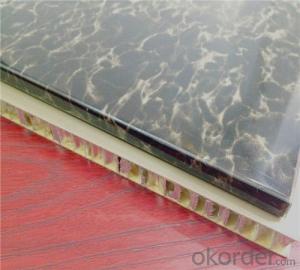

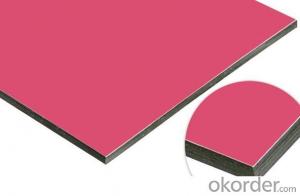

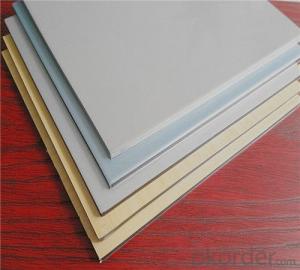

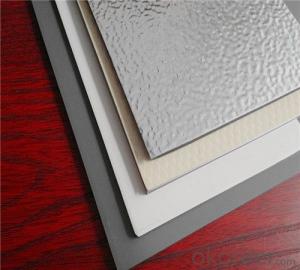

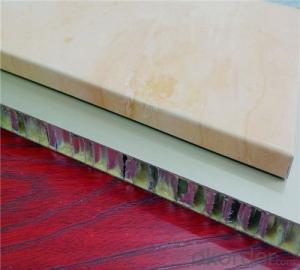

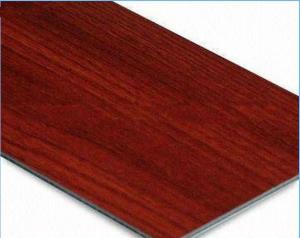

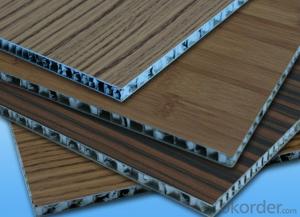

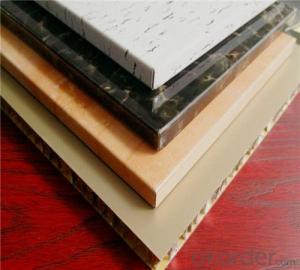

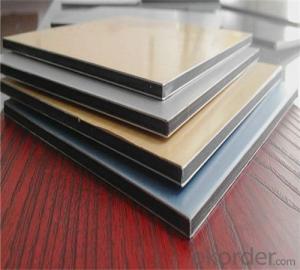

Alucobond is a high-quality composite panel made from aluminum sheets and polyethylene core, known for its durability and aesthetic appeal. This product is widely used in various construction and architectural applications, such as facades, signage, and interior decoration. The cost per square meter of Alucobond varies depending on factors like the thickness of the aluminum sheet, the type of coating, and the size of the order.Alucobond panels are highly sought after for their versatility and strength, making them ideal for both indoor and outdoor applications. They can be used in commercial buildings, residential projects, and public spaces, offering a sleek and modern look while providing excellent protection against weather and wear. The panels are also lightweight and easy to install, which makes them a popular choice for a wide range of projects.

Okorder.com is a reputable wholesale supplier of Alucobond panels, boasting a large inventory to cater to the diverse needs of clients. They offer competitive pricing and ensure that the Alucobond cost per square meter remains affordable without compromising on quality. By partnering with Okorder.com, customers can access a variety of Alucobond products and benefit from their extensive experience in the industry.

Hot Products