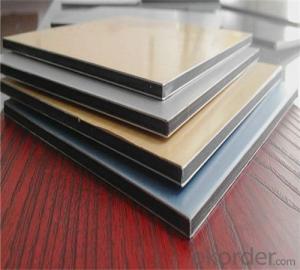

TOBOND pvdf / pe alucobest cladding panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TOBOND PVDF ALUMINIUM COMPOSITE PANEL

TOBOND's production capacity: aluminium composite panel 2 million square meter with three production lines, Aluminium ceiling 1.2million per year, and fabricated solid aluminium panel 260 thousand square meters.The stuffs of TOBOND aluminium composite panel are chosen from high-grate stuff from

ADVANTAGES OF TOBOND ACP

High quality aluminium composite panel.

Low price aluminum composite panel.

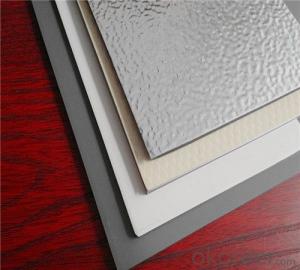

Orange embossed aluminium composite panel.

Light weight and rigid, reducing buildings load, good performance for quakeproof.

Good Smoothingness.

Various color and size for option.

TOBOND ACP Application

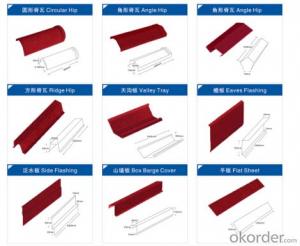

Outer wall cladding, curtain wall.

Redecoration of old buildings outer-wall.

Balconies, indoor partitions.

Units wall cladding

Advertisement signboard

Kitchen and bath room ceiling

Kitchen Cabinet surfacing decoration

Industrial Usage, Vehicle bodies.

Color Chart:

Proceeding Noticed

Portage: panel must be uplifted with its four borders at the same time during portage, do not drag and whop for fear scraping surface of the panel.

Storage: panel must be stored in cool dry place, and placed on flat surface.

Arcing Machining: using professional bending equipment to machining, forcing inchmeal to make the panel reaching bending radian needed. Do not bending one-off.

Installation direction: panels must be install in same direction.

Ripping film: the protective film should be ripped away within 45 days after installation, to avoid survivors left.

- Q: Answer: drawing wire and aluminum plate internal structure Thank you

- The two products mentioned by the questioner are similar, and the difference is that the former is a multi-drawing process and the use of fire-resistant core material.

- Q: What are the materials for making aluminum-plastic panels?

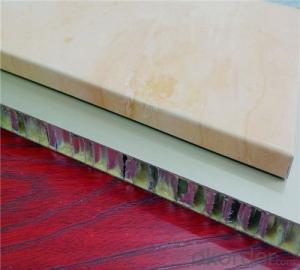

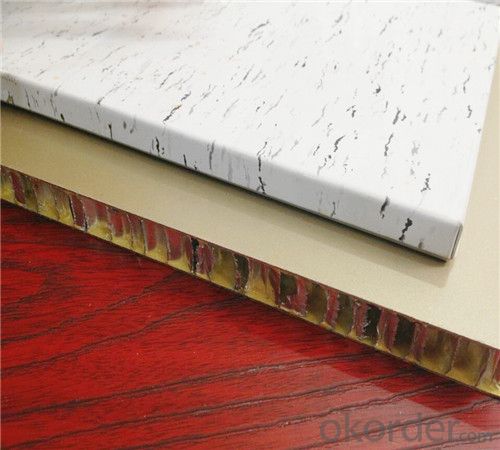

- Aluminum-plastic composite panel, referred to as aluminum-plastic plate, refers to the plastic as the core layer, both sides of the aluminum 3-layer composite sheet, and in the product surface covered with decorative and protective coating Layer or film (known as a coating unless otherwise specified) as a decorative surface of the product.

- Q: What are the benefits of aluminum-plastic board prices?

- Aluminum-plastic composite board is a chemically treated coated aluminum plate as the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials.

- Q: Aluminum-plastic board seamless dry hanging how to make

- If you can not install back, you need to handle or lock the lock on the edge of the box.

- Q: Roof by the wood core board base, do the slope; paste the ordinary aluminum-plastic plate, leaving 0.4cm seam, sealed with structural adhesive, after a winter, structural plastic cracks, causing multiple water leakage, some time ago to make up the seal Glue, the problem is not completely resolved. Will you prawn: If you do a waterproof above, how should construction treatment?

- Aluminum plastic board roof sewing the structure of plastic in the use of only one year on the structure of the plastic cracks appear leakage and fill the seal seal did not completely solve the problem of leakage, the general use of plastic is not good and glue construction Not in place.

- Q: When are the sets of layers? Which item is to be set?

- Aluminum-plastic plate, also known as aluminum-plastic composite panels, is a composite aluminum plate and plastic plate.

- Q: What is the specifications of the aluminum plate

- Aluminum plate material has a standard size: width 1220 mm, length 2440 mm, of course width and length can be customized. Thickness of two kinds of 3 and 4 mm, there are thinner such as 2.5 mm, 10 mm thickness can also do.

- Q: The outer wall is to play on the west is good paint, or aluminum-plastic plate is good?

- Exterior wall paint about 3 years or so

- Q: I want to find a single aluminum aluminum-plastic plate manufacturers, has been unable to find, I hope you know the squeaky sound, it is best to leave the phone or address, thank you! The

- Single-sided aluminum-plastic composite panels in Zhejiang and manufacturers in the production

- Q: What is the aluminum plate and fire board, what is the difference?

- Fire board is the paper immersed in the resin, after high temperature and high pressure treatment, the production of interior decoration surface materials. Fire board with wear, heat, impact resistance, acid and alkali, fire and other characteristics. Fire board can be used for table, desktop, wall, kitchen utensils, office furniture, door surface, hanging cabinet and other locations

Send your message to us

TOBOND pvdf / pe alucobest cladding panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords