Tinplate with Prime Quality for Tin Containers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Tinplate with Prime Quality for Tin Containers

Tinplate Specification

Tinplate, as the name suggests, is coated on both sides with pure tin at various coating weights between 1 and 12 grams per square meter. It has extremely beautiful metalllic luster as well as excellent properties in corrosion resistance, solder ability, and weld ability.

Tinplate Applications

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products.

Chemicals and painting cans

Dry food cans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

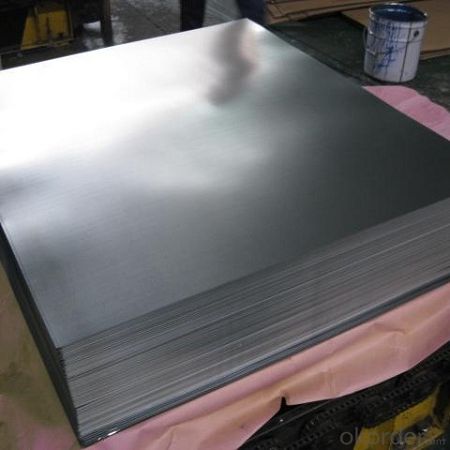

Tinplate Pictures

Tinplate Features

Steel Type: MR, SPCC

Temper(BA& CA): T1- T5, DR8- DR10

Coating: 1.1- 8.4g/m^2

Tickness: 0.15- 0.,50mm

Width: 600-1010mm

I.D: 508mm

Coil weight: 3- 10mt

Passivation: 311

Oiling: DOS

Surface finish: Bright, Stone

Quantity for 20 Feet FCL: 20- 25MT

Package: Seaworthy Export Standard Wooden Pallet

Application

Tinplate is widely used for making all types of containers, electrical machinery parts and many other products

Chemicals and painting cans

Dry food ccans, such as fancy cans, biscuit cans, milk powder cans, tea cans.

Liquid food cans, such as edible oil cans, beverage cans, Tomato paste cans

Sea food cans

Crown corks, easy open ends

Electrical machinery parts

Bakeware and household kitchen parts

Production Standard

GB/T 2520-2000

JIS G3303-2002

DIN EN 10202-2001

ASTM A623M-2002

ISO 11949-1995

- Q: How does tinplate perform in terms of heat resistance?

- Tinplate has a relatively low heat resistance compared to other metal materials. It can withstand moderate temperatures without significant deformation or damage, but it is not suitable for high-temperature applications.

- Q: Can tinplate be used for electrical enclosures?

- Yes, tinplate can be used for electrical enclosures. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against corrosion. This makes it a suitable material for electrical enclosures as it ensures durability and helps maintain the integrity of the enclosed electrical components. Additionally, tinplate is relatively lightweight and cost-effective, making it a popular choice for various industrial applications, including electrical enclosures.

- Q: How does tinplate impact the overall product design?

- Tinplate has a significant impact on the overall product design as it enhances the visual appeal and durability of the product. It provides a shiny and smooth surface, which can be utilized for branding and adding aesthetic elements. Additionally, tinplate offers excellent corrosion resistance, making it suitable for packaging products that require protection from moisture and oxygen. Its malleability allows for intricate shaping and forming, enabling designers to create unique and eye-catching product designs.

- Q: How does tinplate packaging contribute to product protection against UV rays?

- Tinplate packaging helps to protect products against UV rays by acting as a barrier, preventing the penetration of harmful ultraviolet light. The reflective properties of tinplate also minimize the absorption of UV radiation, further safeguarding the product from potential damage caused by exposure to sunlight.

- Q: How is tinplate used in the packaging industry?

- Tinplate is commonly used in the packaging industry due to its excellent properties such as corrosion resistance, durability, and formability. It is often used in the production of metal cans and containers for food and beverages, cosmetics, and other consumer goods. The tin coating on the steel substrate provides a protective barrier against moisture, light, and oxygen, ensuring the preservation and prolonging the shelf life of the packaged products. Tinplate is also used for decorative purposes, as it can be easily printed on, making it an ideal choice for branding and marketing.

- Q: Can tinplate be used for packaging electronic components?

- Yes, tinplate can be used for packaging electronic components. Tinplate is a material made from thin sheets of steel coated with a layer of tin, which provides excellent corrosion resistance and electrical conductivity. It is commonly used in the packaging industry for various applications, including packaging electronic components. The tin coating protects the components from moisture and other environmental factors, ensuring their safety and longevity. Additionally, tinplate offers good formability, making it suitable for creating customized packaging shapes to accommodate different electronic components.

- Q: What's the head iron?

- Tin plate (commonly known as tinplate) refers to the surface coated with a thin layer of metal tin steel plate. The corrosion resistance of SPTE is poor, the general condition of 24H will appear rust smoke test.

- Q: 0.25mm which melting point is low in tin plate and tin plate?

- Tin plated steel sheet and strip, also known as tinplate, the steel plate (belt) surface tin plated, has good corrosion resistance, non-toxic, can be used as packaging material cans, inside and outside the cable sheath, telecommunications instrument parts, flashlight and other hardware.

- Q: How does the printing process affect the durability of tinplate?

- The printing process can significantly affect the durability of tinplate. It forms a protective layer on the surface of the tinplate, making it more resistant to corrosion and external factors that may cause damage. The printing process also enhances the tinplate's scratch resistance, ensuring that the printed design remains intact for a longer period. Additionally, the printing process can provide an extra layer of insulation, protecting the tinplate from heat and moisture, further increasing its durability.

- Q: Can tinplate be used for coffee or tea packaging?

- Yes, tinplate can be used for coffee or tea packaging. Tinplate is a popular choice for packaging due to its durability, resistance to moisture and oxygen, and ability to preserve the aroma and flavor of coffee or tea.

Send your message to us

Tinplate with Prime Quality for Tin Containers

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords