Teranap Geomembrane - Saltworks High-Quality, Low-Priced Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description:

Our product was proved as good mechanic performance, high tearing resistance, strong deformation adaptability, puncture, aging,

ultra-violet radiation, high and low temperature resistance, good waterproof, drainage, anti-seepage , complete width and thickness

specifications, low cost and simple construction.

1.used in landfill caps

2. base liner applications under roads, railways,

3.They are also used for waterproofing of buildings and other similar structures.

2.Product Characteristic:

1),Environmental protection, sanitation (such as solid waste landfills, sewage treatment plants, power plants Chi-conditioning, industrial,

hospital solid waste, etc.) .

2),Water (such as rivers, lakes and reservoirs of the anti-dam, plugging, reinforcement of the canal seepage, the vertical wall of the heart,

slope protection, etc.).

3), Petrochemical (chemical plants, oil refineries, gas storage tanks of the anti-chemical reaction tanks, sedimentation tanks of the lining,

etc.).

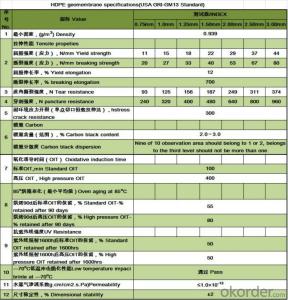

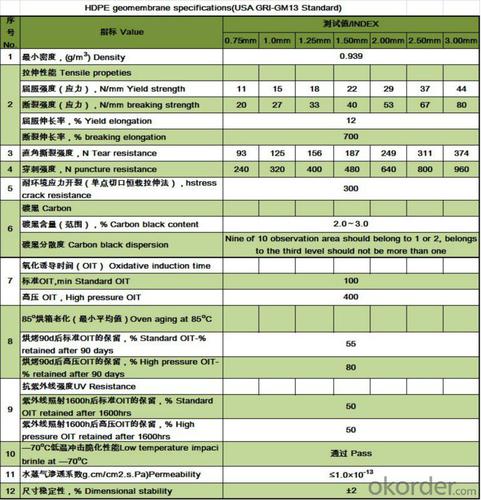

3.Product Specifications:

1.Thickness : 0.1mm---3mm,

2.Length: 50 m -100 m ; width: 4 m -8 m ( according to customer needs )

3.Elongation at break 600%

4.Material: HDPE.

5.Color: Black or as required

4.Reference Picture

- Q: What is the seepage-proof geomembrane?

- Co-extrusion technology is used during the production, the main material of it is high density polyethylene native resin with high quality. It has a low hydraulic permeability and excellent seepage-proof performance. The standard name of HDPE seepage-proof membrane is polyethylene geomembrane, which has a highly efficient molecular density.

- Q: How does the construction of the soft film ceiling?

- 1. First to go to the site to see if there is a condition of installing the keel: Look at the scene to make sure the wall is completed, and woodworking processing part is qualified, the area that need to be plastered should be completed first. First part plastering carpentry part we proposed must be in accordance with the requirements to do, to advance the processing of.2. entering the construction site conditions Licensor hole size lamp, air outlet, first part is fixed according to the design Aluminum Alloy keel keel carpentry requirements drawing well, attention must be right angle connecting to smooth, flat, dense.3. lamp holder, tuyere, light tube plate to and around the keel level, and firmly cannot swing can smooth.4. smoke, ceiling lamps, the first position to make a wooden frame, wooden frame the bottom surface should be polished, and pay attention to the level of height is too low, it is easy to show a trace of.5. before installing ceiling, carefully check the keel joints are solid and smooth, the spray head to stick on the white tape, an outlet should be well handled. When loading the smallpox to first from the middle to both sides of the fixed, while paying attention to size on both sides and pay attention to welding seam to the final straight angle position, pay attention to smooth. Around the well to the smallpox pruning removes. To perfect income effect on the edge. Turn on the light hole. To mark the position of the lamp hole , and carefully stick the PVC lamp ring carefully and accurately on the bottom of the soft film and then remove the excessive smallpox after it is firm. Find the position of the outlet and the light pipe handicap, just as the surroundings, to install the soft film to the aluminum alloy keel, pay attention to keep the angle be smooth.

- Q: Why geomembrane is necessary in modern construction?

- It depends on what it is applied in. Geomembrane can be used in seepage-proof.

- Q: is geomembrane usually produced abroad?

- The so-called domestic produced imported geomembrane is to transfer the products to the bonded area, then resell it. Then we call it imported products. In fact, geomembrane urban construction standards in our country is no different from that of just like American Standard.

- Q: Are geomembranes suitable for use in mining operations?

- Yes, geomembranes are suitable for use in mining operations. They are commonly used as liners in mining applications to prevent the leakage of chemicals, contaminants, and wastewater into the surrounding environment. Geomembranes offer excellent resistance to puncture, tear, and chemical degradation, making them ideal for containing and isolating liquids and solids in mining operations. Additionally, they can be customized to meet specific project requirements, ensuring their suitability for various mining applications.

- Q: Function introduction of geomembrane welding machine

- whose role is to weld two geomembranes into one, just like welding two metal plates into one.

- Q: Are geomembranes resistant to fire?

- Yes, geomembranes are generally resistant to fire. They are typically made from materials like high-density polyethylene (HDPE) or polyvinyl chloride (PVC) that have low flammability and are self-extinguishing. However, the level of fire resistance may vary depending on the specific type and thickness of the geomembrane.

- Q: Are geomembranes resistant to punctures from rocks and sharp objects?

- Yes, geomembranes are designed to be resistant to punctures from rocks and sharp objects. They are typically made from high-strength materials that provide a protective barrier against potential damage, ensuring their durability and long-term performance.

- Q: Can geomembranes be used in stormwater management systems?

- Yes, geomembranes can be used in stormwater management systems. They are often used as liners or covers in stormwater ponds, detention basins, and other detention structures. Geomembranes help to prevent the infiltration of stormwater into the ground, reducing the risk of contamination and protecting groundwater. They also help to control the flow of stormwater, allowing for proper storage and gradual release. Overall, the use of geomembranes in stormwater management systems can improve water quality and reduce the risk of flooding.

- Q: What are the advantages of using geomembranes in landfill gas collection systems?

- There are several advantages to using geomembranes in landfill gas collection systems. Firstly, geomembranes act as a barrier, preventing the escape of landfill gas into the environment. This helps to reduce greenhouse gas emissions and air pollution. Secondly, geomembranes provide a durable and flexible lining that can adapt to the changing conditions of a landfill, ensuring the integrity of the gas collection system. Additionally, the use of geomembranes helps to protect groundwater from contamination by preventing the migration of leachate, a liquid byproduct of landfill decomposition. Overall, the use of geomembranes enhances the efficiency and effectiveness of landfill gas collection systems, making them an essential component of environmentally responsible waste management.

Send your message to us

Teranap Geomembrane - Saltworks High-Quality, Low-Priced Geomembrane

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords