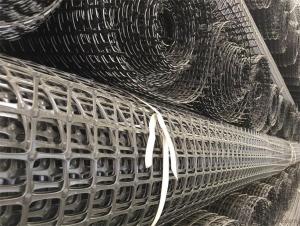

Tenax TT Geogrids for Construction and Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Introduction

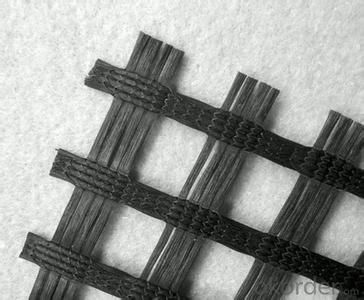

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance

Fiberglass Geogrid Features :

1. Fiberglass geogrid for soil reinforcement

2. Pavement subgrade stabilization

3. Area /Ground stabilization

4. Pavement base reinforcement

5. Working & load transfer platforms

6. Rail Track-bed stabilization

7. Reinforced granular foundation beds

PROPERTIES

1. High tensile strength in both the warp and weft directions;

2. Low elongation;

3. Excellent temperature range;

4. Good anti-age and alkali-resistance;

5. Reduce construction cost, extend service life of road and prevent deflection cracks.

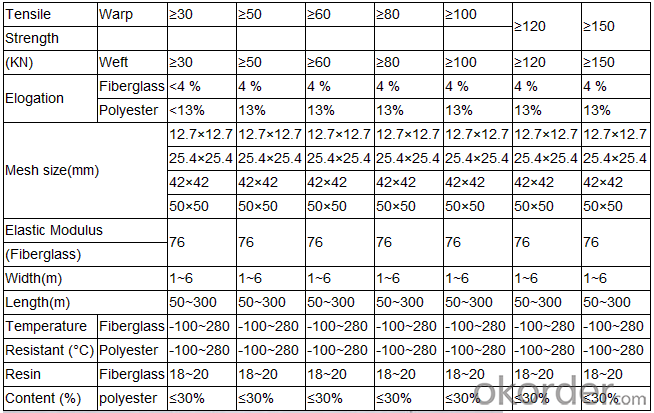

Fiberglass Geogrid Specification:

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

- Q: How do geogrids help in reducing construction labor requirements?

- Geogrids help in reducing construction labor requirements by providing reinforcement and stability to the soil, which eliminates the need for excessive excavation, backfilling, and compaction. This saves time and effort for the construction workers, as geogrids can bear heavy loads and prevent soil movement, reducing the need for extensive manual labor.

- Q: What are the quality assurance measures for geogrid installation?

- Quality assurance measures for geogrid installation include: 1. Proper preparation of the subgrade: Ensuring that the subgrade is well-graded, compacted, and free from any debris or vegetation is crucial before geogrid installation. This ensures a stable base for the geogrid and enhances its effectiveness. 2. Correct geogrid selection: Choosing the appropriate type and strength of geogrid based on the specific project requirements and design specifications is essential. This involves considering factors such as load capacity, soil type, and expected performance. 3. Accurate geogrid placement: Ensuring that the geogrid is correctly positioned and securely anchored is vital for its effectiveness. Careful attention should be paid to the alignment, overlap, and anchorage of the geogrid to prevent any shifting or displacement during and after installation. 4. Proper tensioning: Geogrids need to be adequately tensioned to achieve the desired tensile strength and load distribution. This requires following manufacturer guidelines and using appropriate tensioning equipment to achieve the recommended elongation or strain. 5. Regular inspection and testing: Conducting frequent inspections during geogrid installation helps identify any defects, damage, or non-compliance with specifications. Additionally, conducting pull-out tests or other relevant performance tests can verify the geogrid's adherence to the desired strength and load-bearing capacity. 6. Documentation and record-keeping: Maintaining comprehensive documentation of geogrid installation, including materials used, installation procedures, test results, and any deviations or corrective actions taken, ensures traceability and accountability. This documentation can be valuable for quality control and future reference. By implementing these quality assurance measures, geogrid installation can be carried out effectively, ensuring the desired performance and longevity of the geogrid system.

- Q: How do geogrids help in soil reinforcement?

- Geogrids help in soil reinforcement by distributing the load applied to the soil over a wider area, thereby reducing the pressure on the soil and improving its stability. They act as a reinforcement material, providing tensile strength to the soil and preventing it from sliding or shifting. Additionally, geogrids enhance the cohesion between soil particles, increasing the overall strength and preventing the formation of cracks or failures.

- Q: What are the factors that affect the long-term oxidation resistance of geogrids?

- The factors that affect the long-term oxidation resistance of geogrids include the material composition and quality of the geogrid, exposure to environmental conditions such as temperature and moisture, presence of chemicals or pollutants in the surrounding environment, and the design and installation of the geogrid in the application.

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are generally resistant to microbial attack. Their construction materials, such as polyester or polypropylene, are not easily degraded by microorganisms, making geogrids a durable and long-lasting solution in various applications.

- Q: Are geogrids resistant to chemical attack?

- Yes, geogrids are generally resistant to chemical attack. They are typically made from high-strength polymers like polyester or polypropylene, which have excellent chemical resistance properties. This allows geogrids to withstand exposure to various chemicals commonly found in soil, water, and other environmental conditions, making them a reliable option for reinforcement and stability in different applications.

- Q: What are the differences between geogrids and geocells?

- Geogrids and geocells are both materials used for soil reinforcement and stabilization, but they have distinct differences. Geogrids are typically made of high-strength synthetic materials such as polyester or polypropylene, and they are formed into a grid-like structure. They provide tensile strength to soil, preventing lateral movement and improving load distribution. On the other hand, geocells are three-dimensional cellular structures made from materials like high-density polyethylene. They create a honeycomb-like network that confines soil particles, preventing erosion and promoting load-bearing capacity. While geogrids are commonly used for soil stabilization in applications like road construction, geocells are often employed for erosion control and slope stabilization.

- Q: Can geogrids be used in underground mining applications?

- Yes, geogrids can be used in underground mining applications. Geogrids are commonly used for reinforcement and stabilization purposes in mining operations, specifically in the construction of underground tunnels, shafts, and walls. They provide support to the surrounding soil or rock, enhance stability, and help prevent deformation and collapse. Geogrids are particularly useful in underground mining environments as they are resistant to chemical and biological degradation, have high tensile strength, and can withstand heavy loads.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids are commonly used in civil engineering projects to improve soil stability and prevent soil erosion. They are effective in providing reinforcement and reducing the potential for soil settlement, making them suitable for enhancing the stability of pipelines in various soil conditions.

- Q: How do geogrids help in reducing the need for excavation and replacement of poor soils?

- Geogrids help in reducing the need for excavation and replacement of poor soils by providing reinforcement to the soil, increasing its load-bearing capacity. This reinforcement allows for the construction of structures on weak or unstable soil without the need for extensive excavation and replacement. Geogrids distribute the load more evenly, reducing soil movement and potential settlement, thus eliminating the need for costly and time-consuming excavation and replacement processes.

Send your message to us

Tenax TT Geogrids for Construction and Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords