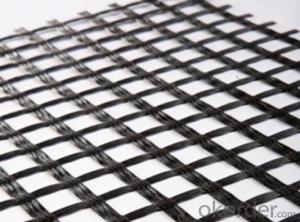

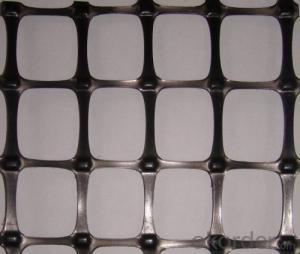

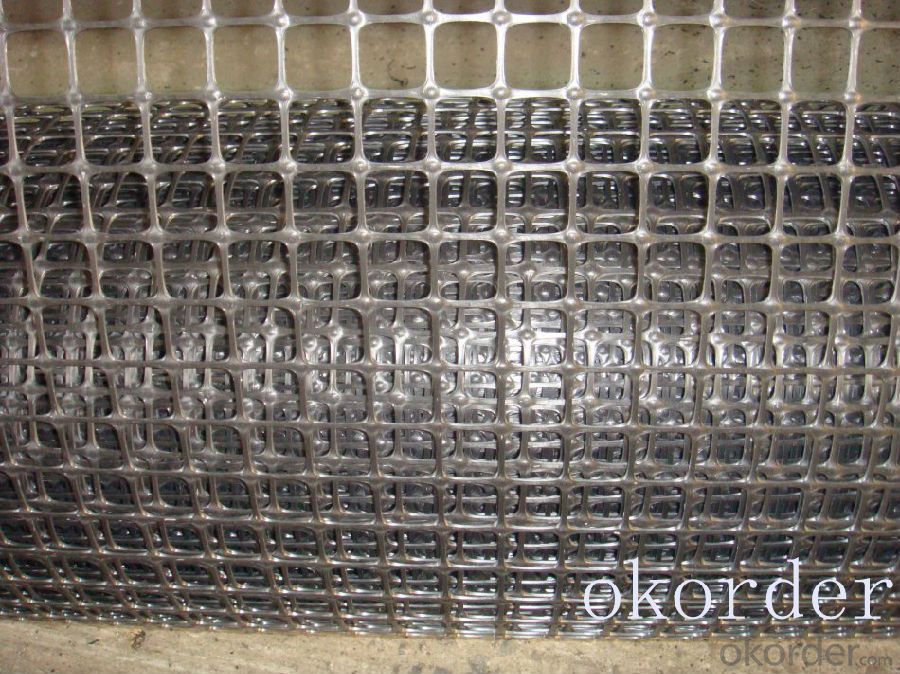

Uniaxial and Biaxial Reinforcement Geogrids for Civil Engineering in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Geogrids are flat structures in polymer (usually high density polyethylene or polypropylene) that are extruded and then pulled: this may be done in one direction (mono-oriented geogrids), or in the two main directions (bi-oriented geogrids).

color:

black

certification:

ISO9001,ISO14001

standard:

GB/T 17639-2008

MOQ:

5000m2

Place of origin:

Shandong,China

packing:

according to customer's need

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geogrids be used in temporary soil stabilization applications?

- Yes, geogrids can certainly be used in temporary soil stabilization applications. Geogrids are commonly employed in various civil engineering projects to reinforce and stabilize soil. They provide temporary support and enhance the strength of the soil, preventing erosion and maintaining stability during construction or other temporary applications.

- Q: Do geogrids affect the permeability of soil?

- Yes, geogrids can affect the permeability of soil. Geogrids are typically used to reinforce soil and improve its stability. They create a barrier that prevents soil particles from shifting, which can reduce the permeability of the soil. However, geogrids can also enhance the drainage properties of soil by providing channels for water to flow through, thereby potentially increasing its permeability in certain cases.

- Q: Product features: high strength, small deformation; creep; corrosion resistance, long service life: steel plastic geogrid with plastic material as a protective layer, which is supplemented with a variety of additives in aging resistance, oxidation resistance, corrosion resistance to acid and alkali, salt and other harsh environment

- Normal should read Zha, but because of the dialect or engineering terminology habits, read Shan, habit, this is just a personal idea.

- Q: How do geogrids improve the performance of geosynthetic tube structures?

- Geogrids improve the performance of geosynthetic tube structures by providing reinforcement and stability. They are typically used as a base or wrap around the tube, enhancing its strength and preventing deformation or collapse. Additionally, geogrids help distribute loads evenly, improve load-bearing capacity, and increase the overall durability and longevity of the structure.

- Q: Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are flexible, high-strength polymer materials that can provide structural support to the surrounding soil or rock mass. They are commonly used to enhance the stability and strength of underground structures by improving their load-bearing capacity and preventing soil or rock movement. Geogrids can be installed during the construction or rehabilitation of tunnels and underground excavations to increase their durability and safety.

- Q: Who knows the laying method of geogrid?

- Geogrid price Description: now all over the country, many manufacturers of geogrid, product prices vary, the price of raw materials and the impact of regional differences,

- Q: What is the elongation of fiberglass geogrid?

- GB/T21825-2008 glass fiber

- Q: Fiberglass grille width

- Width indicators are in 1-6

- Q: The geogrid is not less than 3 meters on each side, what does it mean?

- I think it is not a few geogrid lap width than the roadbed width of three meters, and then backfill roadbed soil after 60 or 80 cm and then the two sides of the geogrid back.Or the design requirements are back folding 30CM

- Q: Classification of plastic geogrid

- First, what is a one-way plastic geogrid: one-way plastic geogrid is a high density polyethylene (HDPE) as raw material, through the extrusion press into a thin plate and then the rules of the hole network, and then the longitudinal tensile geogrid.Two, what are the characteristics of one-way plastic geogrid:1, the polymer into a linear state and the formation of a uniform distribution, high strength of the node of the long elliptical mesh integral structure. This kind of structure has high tensile strength and rigidity, and it provides the ideal chain system of bearing and diffusion of soil.

Send your message to us

Uniaxial and Biaxial Reinforcement Geogrids for Civil Engineering in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords