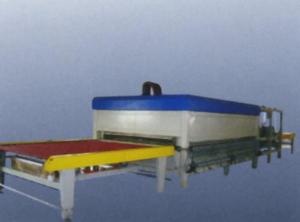

Tempering Furnace-6

- Loading Port:

- Dalian/Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Glass tempering furnace.Mainly termpering glass for domestic furniture,appliances,architectural decoration,shower booths,autombile,trains,ships,etc

- Q: What kinds of equipment are there in FRP production facilities?

- Grinding and mending toolsPainting equipment,There are winding forming and hand paste, and other forms of molding, I do not know the kind of question you ask

- Q: What kind of machinery and equipment do we need for the glass processing plant?

- Look what line you need to go, there are architectural engineering and Art Deco, and others, Art Deco, mainly carved machines, mosaics, sandblasting and painting.

- Q: How much do you charge for a set of insulating glass processing equipment?

- A set of insulating glass processing equipment can be divided into two horizontal and vertical, horizontal and divided into 1 glass washing and drying machine for hot press, mainly is the hollow glass manufacturing combined rubber strip type washing and drying machine; 2 butyl rubber coating machine

- Q: What equipments are used in glass production?

- Cutting: Manual: rake ruler, hand knife machine cut: take piece + cutting machinePretreatment: horizontal drilling, vertical drilling, straight edge machine, double side grinding, water cuttingGlaze, tempered, laminated, hollow and so on.

- Q: Mobile phone glass engraving machine capable of processing large size?

- It depends on how large your equipment is. Many companies have carved machine alone making large stroke, according to the special processing of glass. Cell phone glass is no bigger than a tablet! Can be carved machine large stroke and biaxial processing of two pieces of flat glass. Let alone the cell phone

- Q: How much will it cost to machine ordinary glass into toughened glass? Where can I buy it?

- Different from the raw material, the ordinary glass can be burned by tempering furnace and cooled into toughened glass. Machine made Guangzhou more, of course, more expensive abroad, and good quality. Generally open a steel plant, no 4 million, do not open.

- Q: Can the recycled waste glass be re processed into glass containers (such as beverage bottles, etc.)?

- It's simple. Any glass factory can do that,I am a sales officer in the factory, and I am not sure about the technology and equipment,

- Q: Organic glass (PMMA) hole thread processing, how to eliminate burr? Urgent!

- Plexiglass container opening method: 100mm diameter below the hole of woodworking cutting blade, with portable cutting machine can be completed, or use electric drill direct drilling. If the opening is required, the high precision needs to be machined with laser cutting.

- Q: Can glass fiber reinforced plastics be machined with high precision?

- The so-called glass fiber reinforced plastic (FRP), also known as GRP, that is, fiber reinforced plastics.(1) generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastics made from glass fiber or its products are referred to as glass fiber reinforced plastics or glass fiber reinforced plastics.(2) because of the variety of resin used, it is called polyester glass fiber reinforced plastics, epoxy glass fiber reinforced plastics and phenolic resin glass fiber reinforced plastics. Light and hard, non conductive, high mechanical strength, less recycling, corrosion resistance. It can be used instead of steel to make machine parts, automobiles, ship shells, etc..

- Q: How much does it cost to open a glass grinding machine shop?

- If the ordinary straight side, the machine is about forty-five thousand. Beveling machine ninety-five thousand or so. Shape machine about twenty-three thousand, drilling machine about twenty-three thousand.

We are a professional, experienced ,hi-tech enterprise, specialized in developing and manufacturing glass tempering systems .in the past years ,it has been engaged in the research and development of deep processed glass products and equipments.

1. Manufacturer Overview

| Location | Qinghuangdao, China |

| Year Established | 2002 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Northern Europe; Southern Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Tempering Furnace-6

- Loading Port:

- Dalian/Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 3 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords