Supply H Beam Profile with Jis Material Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

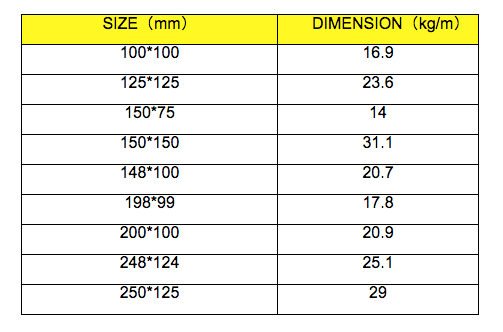

6. Sizes:

Usage & Applications of Hot Rolled Structural Steel H Beam

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

Packaging & Delivery of Hot Rolled Structural Steel H Beam

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: What are the typical weight and mass of steel H-beams?

- The typical weight and mass of steel H-beams can vary depending on their size and specifications. However, as a general guideline, a standard H-beam with a length of 20 feet can weigh around 200 to 300 pounds per foot, with a total mass ranging from approximately 4,000 to 6,000 pounds.

- Q: Can steel H-beams be used in data center structures?

- Yes, steel H-beams can be used in data center structures. Steel H-beams are commonly used in construction due to their high strength and durability. They provide structural support and can effectively bear heavy loads, making them suitable for use in data centers where there is a need for strong and stable framework to support the equipment and infrastructure.

- Q: Can steel H-beams be used for supporting railway structures?

- Yes, steel H-beams can be used for supporting railway structures. H-beams are commonly used in construction projects for their strength and durability. They are able to support heavy loads and provide stability, making them suitable for railway structures such as bridges, platforms, and support beams. The use of steel H-beams ensures the necessary strength and safety required for railway infrastructure, as they can withstand the weight of trains and the forces exerted on the structures. Additionally, steel H-beams are readily available in various sizes and can be easily fabricated and installed, making them a popular choice for railway construction projects.

- Q: Can steel H-beams be used for shopping malls?

- Yes, steel H-beams can be used for shopping malls. Steel H-beams are commonly used in construction due to their high strength and durability. They are capable of supporting heavy loads, making them suitable for large structures like shopping malls. Additionally, steel H-beams provide flexibility in design, allowing for open and spacious layouts commonly found in shopping malls. Their fire resistance properties also make them a safe choice for such commercial buildings. Overall, steel H-beams are a popular choice for constructing shopping malls due to their strength, durability, and design versatility.

- Q: How do steel H-beams contribute to the overall stability of a building?

- Steel H-beams contribute to the overall stability of a building by providing structural support and load-bearing capacity. The H-shape design allows for even distribution of weight and enables the beam to efficiently bear heavy loads. Additionally, the rigid nature of steel helps to resist bending, twisting, and deformation, thereby enhancing the structural integrity of the building.

- Q: How do steel H-beams contribute to indoor air quality in buildings?

- Steel H-beams play a minimally direct role in contributing to indoor air quality in buildings. As load-bearing structural elements, H-beams are typically made from steel, which is an inert material that does not release any volatile organic compounds (VOCs) or harmful emissions. Unlike certain building materials such as wood or certain types of plastics, steel H-beams do not emit any pollutants or allergens into the indoor air. However, it is important to note that the overall indoor air quality of a building is influenced by a wide range of factors, including ventilation systems, building materials, furniture, and occupant activities. Steel H-beams indirectly contribute to a healthy indoor environment by providing a sturdy and durable framework for the building, allowing for proper ventilation and effective air circulation. Furthermore, steel H-beams are commonly used in construction projects due to their fire-resistant properties. In the event of a fire, steel does not release toxic gases or smoke that can compromise indoor air quality. This enhances the safety of the building occupants and minimizes the potential health risks associated with poor air quality during fire incidents. In conclusion, while steel H-beams themselves do not directly impact indoor air quality, they contribute to a healthier indoor environment through their non-emissive nature and fire-resistant properties. The overall indoor air quality is influenced by a combination of factors, and the use of steel H-beams helps create a safe and sustainable building structure that supports good air quality.

- Q: Do steel H-beams require any special maintenance?

- Special maintenance is not typically required for steel H-beams. However, extending their lifespan and maintaining their structural integrity can be achieved through regular inspections and preventive measures. The following maintenance practices are recommended for steel H-beams: 1. Conduct regular inspections: It is important to periodically inspect the beams for signs of corrosion, deformation, or structural damage. Cracks, rust, loose connections, or any other signs of wear and tear should be promptly addressed to prevent further damage. 2. Keep the beams clean: Removing dirt, debris, and other contaminants from the beams helps prevent corrosion and deterioration. Regular cleaning with a mild detergent and water can help maintain their appearance and durability. 3. Prevent rust: Applying a rust-resistant coating or paint to the beams can prevent corrosion. It is essential to use a high-quality coating specifically designed for steel structures and follow the manufacturer's instructions for proper application. 4. Address vibration and movement: H-beams may experience vibrations or movement due to factors like heavy machinery or seismic activities. Regularly check for excessive movement or vibration and promptly address them to prevent further damage. 5. Ensure proper load distribution: Properly distributing the load on the H-beams is crucial to avoid overloading or excessive stress. Consulting with a structural engineer to determine the appropriate load capacity and ensuring it is not exceeded is recommended. In conclusion, while steel H-beams are durable and require minimal maintenance, regular inspections and preventive measures are essential for long-term performance and safety. It is advisable to consult with a professional engineer or contractor to determine specific maintenance requirements based on the project and environmental conditions.

- Q: Can steel H-beams be used for office buildings or commercial complexes?

- Yes, steel H-beams can definitely be used for office buildings or commercial complexes. Steel H-beams are commonly used in the construction industry due to their strength, durability, and versatility. They provide structural support and stability to the building, making them suitable for large-scale projects like office buildings or commercial complexes. Their high load-bearing capacity makes them ideal for spanning long distances and supporting heavy loads, which are common requirements in such structures. Additionally, steel H-beams offer the advantage of being fire-resistant, which is crucial for the safety of occupants in commercial buildings. Overall, using steel H-beams in office buildings or commercial complexes ensures a strong and reliable structural framework that can withstand the demands of these types of structures.

- Q: Can steel H-beams be used for supporting shipyard structures?

- Yes, steel H-beams can be used for supporting shipyard structures. They are commonly used in the construction of shipyards due to their high strength and load-bearing capacity. Steel H-beams provide structural stability and can withstand the heavy loads and dynamic forces exerted by ships during construction, repair, or maintenance.

- Q: Can steel H-beams be used for rooftop structures?

- Yes, steel H-beams can be used for rooftop structures. They are commonly used in construction for their strength, durability, and ability to support heavy loads. Steel H-beams provide structural support and can be an ideal choice for rooftop structures due to their high load-bearing capacity.

Send your message to us

Supply H Beam Profile with Jis Material Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords