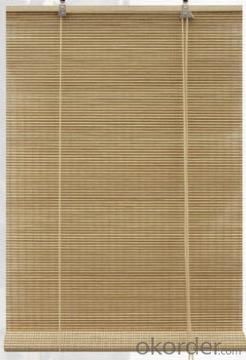

sunscreen fabric design with valance sun shade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the sun shade

| max size | 240W*300Hcm |

| openness factor average | 1-20% |

| top, bottom rail and cassette valance material | aluminum alloy |

| roller tube size | 28 or 38 mm just depends on your window size |

| flammability | class 1 |

| MOQ | 500 pcs |

| bead chain stress heavy | 8kg |

| sample lead time | 2-3 days |

| easy to clean | simply rinse with water and soap and scrub with a soft brush |

Varous systems for your choice

1) The roller blinds can be of chain control, remote control, bluetooth control.

2) If with electric motor, mains power and battery power both are available.

Fabric | Sunscreen / Blackout | ||

COMPOSITION | 30% Polyester,70% PVC | ||

WIDTH(cm) | Sunscreen183/250/300 | ||

FIRE CLASSIFICATION | NFPA 701-2004 TM#1, California Administrative Code, Title 19, BS 5867 Part2 TypeB | ||

ANTI-ULTRAVIOLET | 92%---100% | ||

Usage | Home, office, cafe, school,etc. | ||

Install | Can be mounted on the wall or ceiling | ||

FEATURE

1. Plastic dense chain bead:

The friction and break between chain and clutch are little, equal load-carrying, smooth and steady running, Long service time.

2. Plastic thin chain bead:

The usability of thin chain bead is as similar as the dense. Slight low strength, the drape property is much better.

3. stainless chain bead:

High strength, better drape property, lower influence of circumstance, more durable, a little expensive, used in high and heavy blinds

- Q: The weight of the textile fabric

- We as a textile fabric salesman, the general situation is this, the guests gave a piece of cloth or give a detailed specification, we need to analyze the offer. On the analysis of the fabric, this article has a lot of very detailed, and I will not say here. Fabric cost accounting, the general idea is:

- Q: Textile fabric classification, dyeing and finishing processing is what?

- This question is not a sentence 2 can solve the answer, look at the Chinese fabric finishing textile Daquan

- Q: Textile raw materials of mineral fiber

- The preparation of chemical fibers, usually the first natural or synthetic polymer or inorganic materials made of spinning melt or solution, and then filtered, measured by the spinneret (plate) out into a liquid stream, then Solidified into fibers. At this time the fiber is called the primary fiber, its mechanical properties are poor, must go through a series of post-processing processes to meet the textile processing and use requirements.

- Q: Processing of textiles, processed products were detected formaldehyde exceeded, how to deal with

- Formaldehyde is volatile, soluble in water substances; according to this feature, so formaldehyde after washing or ventilation will disappear

- Q: What are the Advantages and Disadvantages of PE and PVC in Textile Fabrics

- PVC is actually a vinyl polymer, the material is a non-crystalline material. PVC materials in the actual use of often added stabilizers, lubricants, auxiliary processing agents, colorants, impact agents and other additives

- Q: What is eco textile?

- January 27, 2000, the State Environmental Protection Administration approved and began to implement the "eco-textile" standard, indicating that the state of clothing on human health concerns. Ecological textiles should meet the following technical requirements 1. Products shall not go through chlorine bleaching. 2. Products shall not be anti-mildew finishing and flame retardant finishing. 3. No pentachlorophenol and tetrachlorophenol may be added to the product

- Q: DTY FDY POY What are the textile raw materials?

- FDY: full stretch silk. Full name: FULL DRAW YARN. The synthetic filament filaments were further prepared by spinning. The fibers have been fully stretched and can be used directly for textile processing.

- Q: What are the raw materials for textiles?

- To this many of the textile area to the categories are: fabric, knitwear, yarn rope, towel blanket Pa, non-woven fabrics and special textiles. Fabrics according to their use of raw materials to distinguish, there are: cotton, silk, woolen cloth, linen and so on. Knitwear with sweatshirts, pullovers, gloves, socks, camel hair and so on.

- Q: Application of Biological Enzyme in Textile Processing

- Laccase in the textile processing applications: laccase is an oxidoreductase, Connaught letter of the company's Denilit II S is through the genetically modified Aspergillus niger laccase, can be cowboy clothing antique finishing process, get the fabric feel thick , Smooth surface, vouchers, bright color, elegant.

- Q: What is the role of textile degreasing in life?

- Textile degreasing agent in the use of textile processing is unusually common, and the use of the remaining additives is definitely more difficult to practice in terms of light. Therefore, the textile degreasing agent in the textile auxiliaries in this family is particularly popular

Send your message to us

sunscreen fabric design with valance sun shade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches