Subgrade Stabilization Geotextile - Polypropylene Non-Woven Geotextile Drainage for Highway / 1000g

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1

PP (Polypropylene) woven geotextile for Road

It is a reinforcement material and can improve performance and durality in roadway and soil applications.

The equipment is introduced from Germany. This geotextile can be made of polypropylene (PP), or polyester (PET), Polyvinyl or synthetic fiber on needle punch machine. The mass is available from 100gsm/m² to 1000gsm/m² and the width available from 2.0m-8m, monolayer or multilayer (reinforcement geotextiles), long fiber or short fiber. Color: all kinds of color are available. The annual production ability is 10 million square meters.

The fabric can also be heat treated by infrared at customer's requirements. Our geotextile are UV stabilized to give protection against aging under exposure to natural ultra-violet light and anti-acid and alkali.

The major functions: envormental,separation, filtration, drainage, reinforcement, protection, and liquid barrier.

Application: It is widely used in the areas of railway, airport,,highway, water conservancy, dam, tunnel, subway, environmental protection and so on.

Application range

1.Reinforcement: Used in the constructions of highway, railway, airport, dam, prevent slope dike, retaining wall, etc. to improve stability.

2.Protection: To prevent the bank from eroding by wind, wave ,tidal and rain. Used for the projects such as revetment, slope protection and bottom protection, anti-soil erosion,etc.

3.Filtration: Used as filtering layer of dike, the dam, river and coast stone , slope, retaining wall to prevent sand grain through and allow freedom through of air or water.

Technical Parameters

No. | Project | Iindex | ||||||

20-15 | 30-22 | 40-28 | 50-35 | 60-42 | 80-56 | 100-71 | ||

1 | Breakage Strength KN/m ≥(LD) | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

2 | Breakage Strength KN/m ≥(LD) | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

3 | Elongation Rate %≤(LD, TD) | 28 | ||||||

4 | Trapozoidal Tearing Strength KN≥(LD) | 0.3 | 0.45 | 0.5 | 0.6 | 0.75 | 1 | 1.2 |

5 | Burst Strength KN≥ | 1.6 | 2.4 | 3.2 | 4 | 4.8 | 6 | 7.5 |

6 | Vertical Permeability Coefficient cm/s | 10-1~10-3 | ||||||

7 | Sieve size (O95.) mm | 0.085~0.5 | ||||||

8 | Unit weight g/m2 | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

9 | Variation % | ±10 | ||||||

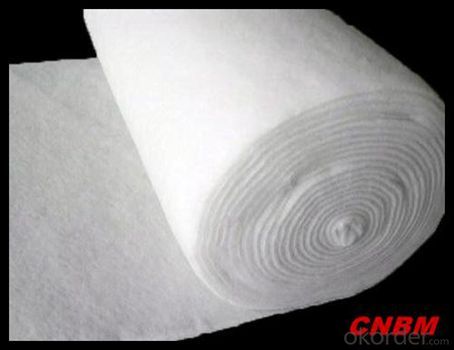

Detailed Images

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Is there a geotextile between the waterproofing membrane and the rigid layer?

- Need to prevent the waterproof layer from being pierced. Huazhi geotextile material manufacturers

- Q: What are the specifications for geotextiles used in geosynthetic tubes?

- The specifications for geotextiles used in geosynthetic tubes may vary depending on the specific application and project requirements. However, some common specifications include factors such as the tensile strength, permeability, UV resistance, puncture resistance, and filtration properties. It is important to consider the specific project conditions and engineering design to determine the suitable specifications for geotextiles used in geosynthetic tubes.

- Q: How do geotextiles help in soil reinforcement?

- Geotextiles help in soil reinforcement by providing a strong and stable base for the soil. They act as a barrier between the soil and other materials, preventing erosion and maintaining the integrity of the soil structure. Additionally, geotextiles distribute the load evenly across the soil, reducing the risk of settlement and increasing the overall stability of the area.

- Q: What are the installation guidelines for geotextiles used in erosion control blankets?

- The installation guidelines for geotextiles used in erosion control blankets typically involve the following steps: 1. Site preparation: Ensure that the area where the erosion control blanket will be installed is properly graded and free of any debris or vegetation. 2. Unroll the geotextile: Start by unrolling the geotextile fabric along the slope or area where erosion control is needed. Make sure to overlap the fabric by the specified amount to ensure complete coverage. 3. Secure the fabric: Use stakes or landscape pins to secure the geotextile to the ground, especially at the edges and corners. This will prevent it from shifting or being displaced during installation or heavy rainfall. 4. Seam connection: If multiple rolls of geotextile fabric are required, ensure that they are properly overlapped and securely connected using a recommended seam connection method. This will ensure a continuous and seamless coverage. 5. Anchoring: In certain cases, additional anchoring may be required to provide extra stability. This can include using sandbags, rocks, or other suitable materials along the edges or across the surface of the geotextile fabric. 6. Vegetative cover: If the erosion control blanket is designed to support vegetation growth, follow the recommended guidelines for seed or plant installation. This may involve spreading seeds or planting live vegetation through the geotextile fabric. It is important to note that these guidelines may vary depending on the specific erosion control blanket and geotextile manufacturer, as well as the site and project requirements. It is always recommended to refer to the manufacturer's installation instructions and consult with a professional engineer or erosion control specialist for proper installation and best results.

- Q: What is the difference in role of earth anchors and geotextiles in the construction of retaining wall?

- Geotextiles prevent the infiltration of the natural, insitu soil into sand or structural gravel that you may place as a foundation to the retaining wall. You can think of it as a membrane that keeps the two types of material of different densities, from gradually mixing together. A free standing retaining wall will likely not be successful as the pressure of the retained soil behind the wall will build up due to settlement, and eventually cause the wall to topple. Earth anchors that tie into the wall and extend into the backfill material (retained earth) serves to support the wall and keep it from failing.

- Q: Can geotextiles be used for reinforcement of railway embankments?

- Yes, geotextiles can be used for reinforcement of railway embankments. Geotextiles are often used in civil engineering projects to improve the stability and performance of soil structures. In the case of railway embankments, geotextiles can be placed beneath the ballast layer to enhance the load-bearing capacity of the soil, prevent erosion, and improve overall embankment stability.

- Q: How do geotextiles help with vegetation establishment?

- Geotextiles help with vegetation establishment by providing a stable and favorable environment for plant growth. They act as a barrier against weed growth, erosion, and sedimentation, while allowing water and nutrients to pass through. Geotextiles also protect newly planted vegetation from wind damage and promote healthier root development, leading to successful establishment and growth of plants.

- Q: Geotextile was wetted by what kind of treatment

- Geotextile was originally in the project to play a reinforced, protective, filter effect. So geotextile is not afraid of water, not afraid of wet, so do not fear wet. Damped geotextile is easy to get dirty, easy to carry. Generally dried can be used, do not need to do any treatment.

- Q: How do geotextiles help in erosion control?

- Geotextiles help in erosion control by providing a barrier that separates soil layers and prevents them from being washed away by water or wind. They stabilize the soil, promote vegetation growth, and enhance drainage, ultimately reducing erosion and maintaining the integrity of the landscape.

- Q: Can geotextiles be used in retaining wall construction?

- Yes, geotextiles can be used in retaining wall construction. They are often used as a reinforcement material to improve the stability and longevity of the wall. Geotextiles can help in preventing soil erosion, providing drainage, and increasing the overall strength of the retaining wall.

Send your message to us

Subgrade Stabilization Geotextile - Polypropylene Non-Woven Geotextile Drainage for Highway / 1000g

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords