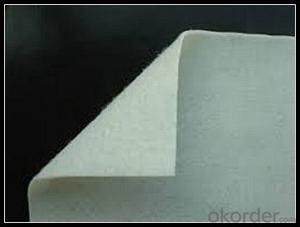

Stabilization Geotextile Fabric - Polypropylene Nonwoven Industrial Geotextile for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Geotextile

Geotextile is a non-woven geosynthetic material, manufactured by needle-punch method. Having wonderful physical and mechanical qualities (high tensile strength, mechanical damage resistance, acid and aggressive biological environment resistance) geotextile is widely used in civil and road construction, oil-gas area, for domestic needs, melioration and landscape architecture.

Polyester fabrics is not water soluble and that is why environmental friendly.

Applications

Filtration

gabions and river mattresses

roads

concrete retaining walls.

Separation

the separation of good and poor roadway layer work materials

roads over soft soils.

Roadway lining

provides waterproofing qualities for layer works and wearing courses.

Drainage of

sports fields

railway tracks

behind concrete walls & embankments.

Membrane liner protection

gabion structures

landfill sites.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

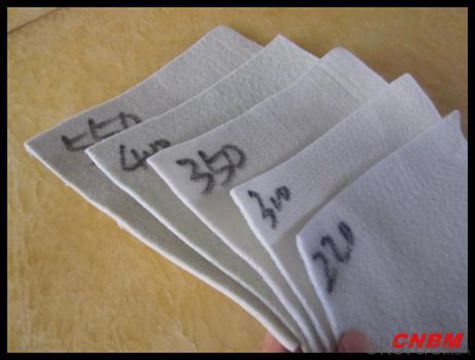

A: Yes, please check the pictures:

- Q: Can geotextiles be used in geosynthetic reinforced walls?

- Yes, geotextiles can be used in geosynthetic reinforced walls. Geotextiles are commonly used as a separation and filtration layer in geosynthetic reinforced walls. They help prevent the migration of fine particles and provide stability to the soil layers, enhancing the overall performance and longevity of the wall.

- Q: Are geotextiles suitable for use in waste containment systems?

- Yes, geotextiles are suitable for use in waste containment systems. They provide excellent filtration and separation capabilities, preventing the migration of fine particles and facilitating proper drainage. Geotextiles also enhance the stability and integrity of waste containment systems by acting as a barrier against puncture and tear. Additionally, they help to control erosion and soil erosion, ensuring the long-term effectiveness of waste containment structures.

- Q: How do geotextiles contribute to sustainable drainage systems?

- Geotextiles contribute to sustainable drainage systems by providing effective filtration and separation of soil layers, preventing clogging and improving water infiltration. They also help in reducing erosion and promoting vegetation growth, thus enhancing the overall sustainability and longevity of drainage systems.

- Q: Can geotextiles be used in green roof systems?

- Yes, geotextiles can be used in green roof systems. They can serve multiple purposes such as providing drainage, filtration, and separation layers. Geotextiles help to control water flow, prevent soil erosion, and promote healthy plant growth in green roofs.

- Q: What are the key factors affecting the interface friction of geotextiles?

- The key factors affecting the interface friction of geotextiles include the type of geotextile material used, the surface roughness of the adjacent materials, the normal stress applied to the interface, the moisture content of the materials, and the degree of compaction.

- Q: How do geotextiles help with ground reinforcement?

- Geotextiles help with ground reinforcement by providing a strong and stable support system. They are typically made of synthetic materials and are placed beneath the ground surface to distribute the load and prevent soil erosion. The geotextiles act as a barrier, allowing water to pass through while retaining soil particles, which helps in maintaining the stability of the ground and preventing any potential damage or failure.

- Q: Can the roof waterproof with geotextiles?

- According to personal circumstances, but suggested to find professional personnel assessment. First of all, professional construction, roof waterproofing is a very test of professional skills work, need to hold the local construction administrative departments issued the job certificate. Professional construction units will be detailed survey and roofing drawings. Survey the actual situation of statistics, regional climate, housing and other factors, with the data obtained to develop professional construction program. Construction will be the future may cause housing flaws in the defect to be repaired, so to prevent the future. Secondly, qualified materials, roof leakage in China, about 20% of the material is unqualified, resulting in leakage of the roof of the situation. So in the choice of roof or roof of the material must meet the relevant national standards, and generally qualified roofing materials will have qualified documents and quality inspection departments of qualified certification. In the choice of decoration materials can request the relevant proof, at the same time to check the decoration materials production date, brand, batch number, specifications and so on information to ensure that the quality of qualified roofing materials. Finally, the acceptance of the project, because the roof or roof environment is very complex, so its decoration construction requirements must be strict. The process needs to have a waterproof, leak-proof, anti-seepage function, the summer high temperature can be high temperature, anti-ultraviolet, cold winter to have anti-freeze-resistant low temperature, daily sunshine to have anti-aging and so on.

- Q: Are geotextiles suitable for use in bridge construction?

- Yes, geotextiles are suitable for use in bridge construction. Geotextiles provide several benefits such as soil stabilization, erosion control, and drainage, which are crucial in bridge construction to enhance the overall performance and longevity of the structure.

- Q: What are the maintenance requirements for geotextile installations?

- The maintenance requirements for geotextile installations typically involve regular inspection to ensure the fabric is intact and functioning properly. Any signs of damage or deterioration should be repaired or replaced promptly. Additionally, geotextiles may require occasional cleaning to remove debris or sediment that can affect their performance. Overall, proper maintenance practices can help prolong the lifespan and effectiveness of geotextile installations.

- Q: Do you need to use geotextile for construction site? Mainly used where?

- What do you want to specify? In what position. Are generally used in waterproof engineering.

Send your message to us

Stabilization Geotextile Fabric - Polypropylene Nonwoven Industrial Geotextile for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords