Steel Tile Roll Forming Machine with CE&ISO

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of steel tile roll forming machine:

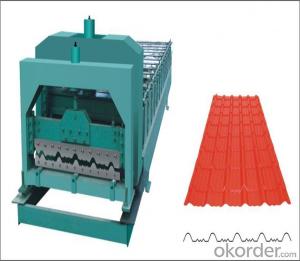

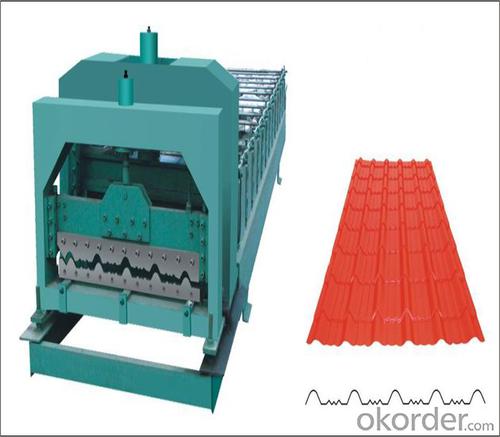

Steel tile roll forming machine consists of feeding, forming, after forming cutting production of color plate smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in industrial and civil buildings, such as workshop, warehouse, gymnasium, exhibition halls, theaters and other surface and wall.

2.Main Features of the steel tile roll forming machine:

The tile roll forming machine has the advantages of good corrosion resistance, colorful, beautiful appearance, convenient processing molding and the advantages of the the original strength of the steel plate and the cost is low.

First generation and second generation "automatic moulding color tile equipment" adopt "swinging cylinder driving sliding table", "swinging cylinder" belong to "moulded caigang watts equipment" is "extremely fragile" in accessories, if the forming speed is too fast, cause a large sliding table shock, buffer vibration easily, cause the tiles have crack, is the first and the second generation "stubborn" in the color tile equipment. So the fastest forming up to 6 pieces per minute.

3.Steel tile roll forming machine Images

4.Steel tile roll forming machine Specification

Steel tile roll forming machine has a lot of parameters to set, by using the text screen or touch screen setting. Parameter setting, which has two kinds of equipment parameters and user setting.

Equipment parameters: single pulse length, impulse, molding, molding time, cutter and so on.

User parameters: the number, length, pitch, the first section, small section, section number, preloading and so on.

Main moter power 5.5KW

Hydraulic station power 4KW

Hydraulic oil pump CB-E310

Sprocket P-25.4

Roller station 13

Yield strength 32MPa

Diameter of principal axis 90MM

Material of roller 45#steel hard chrome plating

Processing speed 10-15m/min

Thickness 0.3-1.2 mm

Installation dimension about(L*W*H) 7.5*1.3*1.5M

Total weight 4.2T

Equipment parts includes:roll forming system, hydraulic system, PLC frequency conversion control system, counter, cutting system,decoiler .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1). What’s your machine installation & commissioning, training:

1or2 technicians will be dispatched to Buyer’s plant for installation & commissioning. Work period: in 5 days. The expense of round trip tickets, accommodation, safety and interpretation shall be covered by Buyer, additional pay allowance to the technicians.

2). Can you make machine according to my design?

Yes, we have experienced technical team to work out the suitable design for you and confirm with you until you agree.

3). What is the warranty for our machine?

We have one year guarantee, and provide whole life's technical support.

4).Is the machine automatic?

Yes, it can be manual and automatic.

5).what policy for broken parts?

within one year,we offer free parts. If beyond one year,you need to buy by factory cost

- Q: Where can a concrete mixer be used?

- Tile is widely used in home outfit sand, sand pavement tiles grey ash stirring, the botanical garden engineering sand ash mixing, floor concrete mixer, small site masonry mortar and plaster mortar mixing sand dust, electricity, communications and other field operations, seedling fertilizer mixing, family wine could stir scenario. Small mixer is widely used in municipal engineering, small water conservancy projects, rural construction, building decoration, electrical, communications engineering, mountains of bad environment, leisure agriculture, scarification, weeding, etc.

- Q: What are the pros and cons of a concrete mixer?

- The noise is very large when mixing and feed, the installation is more trouble, the use of the dust is very large, the accident, the concrete mixing and the uniform time is not easy to control

- Q: Concrete mixers need to be aware of which things

- The concrete mixer driver must be familiar with the performance and operation of the machine, and wear the protective equipment according to the regulation. Article 2: before work should check whether the transmission clutch and brake is flexible and reliable, climbing rope fights with and without broken wires, transmission components such as the mixer of the big gear, pulley guard is in good condition, whether the motor grounding is good, confirmed rear can work. Article 3: the driver is not allowed to leave the job in the operation of the machine, and when the blender is running, it is forbidden to reach into the mixing bowl with an axe, spade or any other object. Article 4: when the hopper arises, no one shall pass or stay in the hopper. If it is necessary to check and repair, the power should be cut off, and the bucket will be held in the back of the link. Article 5: when the feeding operation is strictly prohibited, the operator will put the head into the hopper and the rack to inspect the loading condition. Article 6: if you need to go into the mixing tube for cleaning, you should disconnect the power supply, remove the fuse, and put the lock on the switch box, or be guarded by a special person.

- Q: What is the difference between a concrete mixer and a mortar mixer

- In power, power, and volume, concrete mixers search large

- Q: How the concrete mixer works

- 1) self-falling blender The inner wall of a self-falling mixer has curved blades. When the cylinder is rotated around the horizontal axis, the blade constantly elevating the material to a certain height, and then the free fall, blending with each other. (2) a strong mixer A strong mixer is mainly based on the shear mechanism. In a blender, there are blades that rotate in a stirring shaft. (3) the selection and application of mixers 1) type selection Concrete mixer should according to the project specific conditions (such as size, length of time limit for a project of quantities) and the requirements on the performance of concrete to be right choice. 2) the production capacity of the mixer is calculated The productivity of the blender is calculated in the following form: Q = 3.6, VK/t1t2t3 (m3 / h) Type t1, t2, t3 - for loading, stirring, discharging time (S); V -- the capacity of the blender; K - the utilization factor of each working time.

- Q: Common type of concrete mixer

- The common concrete mixer is divided into two kinds: self-falling concrete mixer and strong concrete mixer.

- Q: The safe distance of the concrete mixer

- Different devices have different requirements. But the principle is, as far as possible little, and can't always wall during operation. Therefore, maintenance convenience, give attention to two or morethings is good with 3 -- 5 mm, the thickness of the maintenance when the replacement is a flat screwdriver

- Q: For example, what is the more detailed and better td-50 td-80 td-60

- Concrete mixer: mainly consists of mixing, loading and unloading mechanism, water supply system, original motive, drive mechanism, frame and supporting device. Concrete mixer function: To make each component macroscopically homogeneous; To destroy the phenomenon of cement grain reunion and promote the development of dispersive phenomena; The initial water coating on the surface of the cement particle. The effect of the friction between the material particles and the dust film is reduced. Increase the frequency of the unit and the cross frequency of the moving track, accelerate the homogenization

- Q: What is the type of concrete mixer?

- There are a lot of models, depending on what you want to use. I don't know what you know about the machine. It is specially designed for the spraying machine, mixer, etc.

- Q: How does a concrete mixer operate

- If the machine is relatively new, the button will have, it's going to go up, go down, automatically add water, add water by hand, mix it up, mix it up, stop, vibrate

Send your message to us

Steel Tile Roll Forming Machine with CE&ISO

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 PCS

- Supply Capability:

- 100 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords