Steel sheet coil cold rolled buy from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56435 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled Steel coil is a mill product made with a high degree of gauge accuracy and uniformity of physical characteristics.

The smooth deoxidized matte finish gives an excellent base for paint, lacquer and enamel. Box annealing and absence of scale

permit stamping and moderate drawing operations. Sheets bend flat on themselves without cracking. Oiling protects Surface

against rust. The application of surface oil to cold rolled steel coil/sheet is intended to provide protection from corrosion ("rusting")

during shipment and warehousing.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

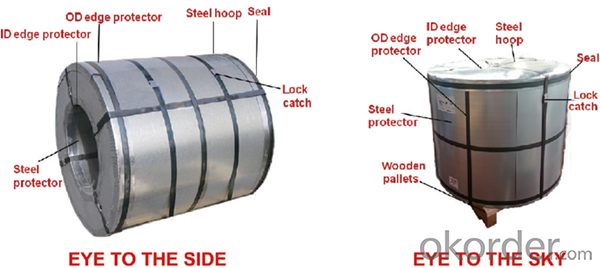

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What are the different methods of punching steel coils?

- For punching steel coils, there are several methods available that vary depending on specific requirements and desired outcomes. The following are some commonly used methods: 1. Mechanical Punching: To create holes in the steel coil, a mechanical press is employed. This method involves utilizing a punch and die set, where the coil is subjected to force from the punch to create the hole. Mechanical punching is best suited for small to medium-sized holes and finds frequent use in high-volume production settings. 2. Hydraulic Punching: In hydraulic punching, hydraulic pressure is utilized to drive the punch into the steel coil. This method is commonly employed for punching larger holes or shapes that demand greater force. Hydraulic punching machines offer precise control and can handle thicker and harder materials. 3. Laser Cutting: Laser cutting is a non-contact technique that employs a laser beam to cut through the steel coil. By directing a focused laser beam onto the coil, the material is melted and evaporated to form the desired shape or hole. Laser cutting provides high precision and can be used for complex shapes and patterns. 4. Plasma Cutting: Plasma cutting involves the use of a high-velocity jet of ionized gas (plasma) to melt and remove the steel coil material. This method is suitable for cutting thicker steel coils and is often employed for larger holes or irregular shapes. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure jet of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can effectively cut various materials, including steel. Waterjet cutting is renowned for its high precision and clean cuts. Each method of punching steel coils possesses its own advantages and considerations. Factors such as material thickness, desired precision, production volume, and cost will determine the most suitable method for a specific application.

- Q: I am a beginner (never played before!) and I am going to try to teach myself since I think it is a lovely instrument. I am fourteen-years-old so I am not 'adult-size', haha. Anyway, what is difference between nylon strings and steel strings?Thanks :)

- Make your choice based on the type of music you intend to play. Nylon strings are used primarily for classical, flamenco and folk music. Steel strings are used for pop, rock, blues, country, folk, bluegrass.... Both types of guitar are tuned the same, so you *can* play any style of music on either guitar. The big difference is in the tone. Nylon strings are rich and full...if perhaps a little mellow. Steel strings are twangy and have a bite to the sound. There are differences in the construction and feel of the guitars, but that's not critical to your decision. Match the guitar to the music you intend to play. At 14 yrs old, you are certainly big enough for a full sized guitar....and I'll bet you're still growing, right? Even full sized guitars still vary in the size of the body. Try a few out to see how well they fit your reach.

- Q: How does coil slitting work?

- Coil slitting is a process used in manufacturing industries to cut large coils of material, such as metal, into narrower strips of desired widths. The coil is unwound and passed through a set of circular blades that make precise cuts along the length of the coil. The blades can be adjusted to the desired width, and the process continues until the entire coil is slit into multiple smaller coils or strips.

- Q: which pokemon has the most steel pokemon???

- Probaly Pokemon Platinum or Pokemon HGSS

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a common method used to join steel coils together or to other steel components, allowing for the formation of strong and durable connections in various applications.

- Q: If a make a dish antenna of steel and of fiberglass, which would be more heavy and also which would be more expensive?

- Why not go one better. An aluminum mesh would be lighter than both for the same size and would not need to be painted. It would probably be more expensive than the steel however.

- Q: How are steel coils transported internationally?

- Steel coils are typically transported internationally using various modes of transportation such as ships, rail, and trucks. Ships are commonly used for long-distance transportation, where steel coils are loaded onto specialized vessels equipped with cranes for efficient loading and unloading. Rail and trucks are often used for shorter distances or for transporting steel coils from the port to the final destination. Specialized equipment such as flatbed trailers or intermodal containers are utilized to ensure the safe and secure transport of steel coils.

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems by being formed into sheets or strips, which are then shaped and welded to create the framework and shelves of the storage units. The high strength and durability of steel make it an ideal material for supporting heavy loads and ensuring the longevity of storage systems.

- Q: hi i was doing a little history project on guns. i was just wondering if anyone could help me find out what material was used before steel and why this material wasnt as good as steel ( its faults)thanks for your help

- The most common was bronze, which was the strongest material that could be cast, at least until the industrial revolution. Until that time, furnaces which could reach temperatures hot enough to melt steel did not exist. The only way to work with steel would have been forging, which means hammering it into shape while red-rot. Obviously, this is not a very practical method for making large thick-walled cannons (though it was done on occasion. Small arms such as pistols and muskets could be easily made of steel by hand forging.) The most practical way to make cannons was pouring molten bronze which melts at significantly lower temperature than steel. Cast iron was also used. Note that Cast Iron contains 3%-7% carbon, compared to steel which only contains between 2% to 0.2% carbon. Due to the excessive carbon content of cast iron, it's melting point is about 500 degrees lower than steel enabling it to be melted with pre-industrial furnaces. Unfortunately, cast iron is also brittle, unlike steel or bronze. This means that a defective or cracked casting could easily explode, sending iron shrapnel everywhere. (Also, maiming and killing the gun crew, an experienced gun crew was as valuable as the cannon itself!) For this reason. Cast iron cannon were usually considered a cheap, risky alternative to expensive but durable bronze.

- Q: I need new sprockets on my GSX-R1, I've heard that alumnium sprockets wear out twice as fast as steel and the difference is not noticable

- i also have a gsx-r1000 06.. always change the sprockets and chain at the same time if you don't it will just wear out the chain faster. all you really need is to go down 1 on the front sprocket and 2 up on the back. stick with the steel sprockets they will save you money in the long run. if you like to wheelie all the time stay away from the aluminum it will wear out quicker.. they also make sprockets that are aluminum on the inside and steel on the outside.

Send your message to us

Steel sheet coil cold rolled buy from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 56435 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords