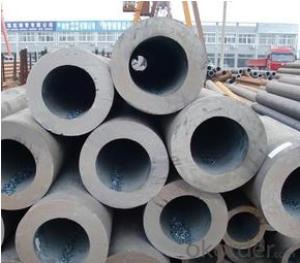

Steel pipe for carbon seamless ,,API P110, cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Thickness: 6 - 50 mm Section

Shape: Round,r

Outer Diameter: 33 - 600 mm

Secondary Or Not: Non-secondary

Application: Fluid Pipe

Technique: Hot Rolled,Hot Rolled,Cold Drawn,Hot Expanded Certification: API Surface Treatment: Beveled end or plain end or varnished as per buyer

Special Pipe: API Pipe Alloy Or Not: Non-alloy

Brand Name: XPY(Xinpengyuan)

Length: 6-12m or according to clients' requirements

Standard: BS 3059-2,JIS G3454-2007,GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB 6479-2000,DIN 1629/3,DIN 2448,ASTM A106-2006,ASTM A53-2007,API 5CT,API 5L,BS,JIS,GB,DIN,ASTM,API

Certification & Standard | SGS & AISI |

Type | Cold Rolled |

Thickness | 0.14mm ~ 1.5mm |

Width | 10mm ~ 1240mm |

Length | As customers' requirements |

Surface finish | NO.2B/ NO.3/ NO.4/ HL/ 8K/ BA |

Chemical Composition (MT)% | (C) :≤0.12% (Si) :≤0.75% (Mn) :≤1.00% (P) :≤0.040% (S) :≤0.030% (Ni) :≤0.60%(Available to contain) (Cr) :16.00~18.00% |

Advantage | Good flexibility, Resistant to corrosion, Thermal Conductivity and lower thermal expansion. |

Application | l Be uesd in manufacturing kitchen ware field. l Auto exhaust parts, Heat exchanger, Washing machinery. l Interior/ Exterior decoration for building l Household Appliances or Appliance components. |

Market | Southeast Aisa, Mid East, Africa, Estern Aisa, Western Europe ,etc. |

Packing | Bundle package, Wooden case, Container or bulk, etc in export standard ;or as customers'requests |

- Q: How are steel pipes insulated for thermal applications?

- Steel pipes are commonly insulated for thermal applications using various materials such as fiberglass, mineral wool, or foam insulation. These insulating materials are typically wrapped around the steel pipes to create a protective barrier that reduces heat transfer. Additionally, a vapor barrier may be installed to prevent moisture condensation. This insulation helps to maintain the desired temperature of the fluid or gas being transported through the pipes and prevents energy loss.

- Q: Can steel pipes be used for oil and gas pipelines?

- Yes, steel pipes can be used for oil and gas pipelines. Steel pipes are commonly used in the oil and gas industry due to their strength, durability, and resistance to corrosion. They can withstand high pressure and extreme temperatures, making them suitable for transporting oil and gas over long distances.

- Q: How are steel pipes marked for identification and traceability?

- Various methods are utilized to mark and trace steel pipes for identification purposes. One prevalent technique involves the use of permanent markers or paint. These markings typically encompass vital information such as the manufacturer's name or logo, the pipe's dimensions and specifications, and the production date or batch number. Aside from surface marking, steel pipes may also be identified through the utilization of tags or labels. These tags are commonly constructed from durable materials such as metal or plastic and are securely affixed to the pipe. They entail comprehensive details regarding the pipe, including its unique identification number, material composition, and any pertinent certifications or standards it adheres to. Another method employed for identification and traceability encompasses the application of barcodes or QR codes. These codes can be scanned using specialized equipment or mobile applications, instantly granting access to comprehensive information concerning the pipe's origin, production process, and quality control measures. Barcodes and QR codes offer a more efficient and automated means of monitoring and tracing steel pipes throughout their lifespan. Moreover, some steel pipes may feature embossed or engraved markings directly on their surface. These markings are typically etched into the metal and possess the ability to withstand harsh conditions, ensuring long-term visibility and legibility. The ultimate objective of marking steel pipes is to guarantee their accurate identification and traceability throughout their lifespan. This aids in quality control, maintenance, and inspection procedures, as well as ensuring compliance with regulatory requirements. Clear and permanent markings enable manufacturers, suppliers, and users to effortlessly track and trace the history and specifications of steel pipes, facilitating better management and accountability in diverse industries such as construction, oil and gas, and infrastructure development.

- Q: How are steel pipes measured and labeled?

- Steel pipes are typically measured and labeled based on their nominal pipe size (NPS), which refers to the inner diameter of the pipe. This measurement is expressed in inches or millimeters. Additionally, steel pipes are often labeled with their schedule or wall thickness, which is represented by a numerical value. The labeling also includes the pipe material, such as carbon steel or stainless steel, and may include other specifications and markings as required by industry standards and regulations.

- Q: How are steel pipes used in the construction of high-rise buildings?

- Steel pipes are commonly used in the construction of high-rise buildings for various purposes. They are primarily used as structural elements, forming the framework and supporting the weight of the building. Steel pipes provide strength and durability, making them suitable for withstanding the vertical and lateral loads experienced by tall buildings. Additionally, steel pipes are used for plumbing and electrical systems, as well as for heating, ventilation, and air conditioning (HVAC) installations. Their versatility, reliability, and ease of installation make steel pipes an essential component in the construction of high-rise buildings.

- Q: How are steel pipes used in the aerospace manufacturing industry?

- Steel pipes are commonly used in the aerospace manufacturing industry for various purposes such as hydraulic systems, fuel lines, and structural components. They offer excellent strength, durability, and resistance to high temperatures, making them ideal for carrying fluids and supporting the overall structure of aircraft.

- Q: How are steel pipes used in the textile industry?

- Steel pipes are commonly used in the textile industry for various applications such as conveying fluids, gases, and chemicals within the manufacturing process. They are used to transport hot water, steam, and air for heating and drying purposes, as well as to supply and distribute water and chemicals for dyeing and printing. Additionally, steel pipes are also utilized in the construction of textile machinery and equipment, providing support and structural integrity to the production line. Overall, steel pipes play a crucial role in ensuring the efficient and reliable operation of textile manufacturing processes.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are used in the telecommunications infrastructure primarily for underground cable installation. They serve as protective conduits that house and secure the fiber optic cables, providing a reliable and durable solution for long-distance communication.

- Q: How are steel pipes protected against corrosion?

- Steel pipes are protected against corrosion through various methods such as applying protective coatings, galvanizing, cathodic protection, and using corrosion inhibitors.

- Q: What do you mean by "SC" in welded pipe SC200? What's the diameter of 200?

- SC in principle, it should be called water gas pipe, also called thick wall steel pipe;

Send your message to us

Steel pipe for carbon seamless ,,API P110, cnbm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords