Steel IPE Heavy Weight I Beam in Europe Standard En10025 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel IPE Description:

Steel IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel IPE is usually made of structural steel and is used in construction and civil engineering. The steel IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel IPE Form:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel IPE Images:

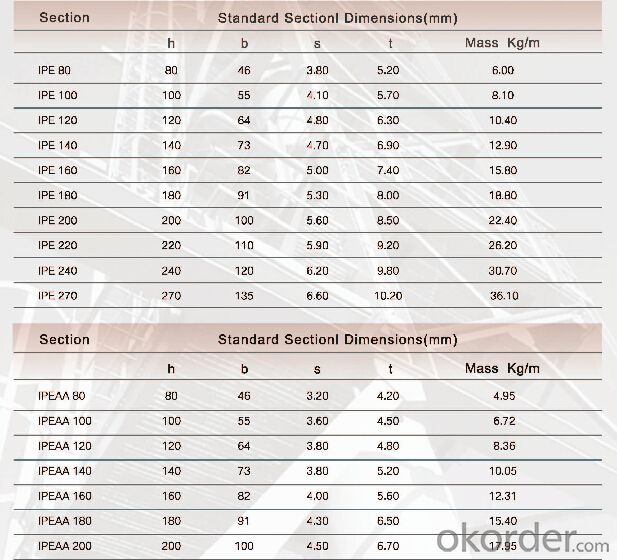

4. Steel IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do Steel I-Beams compare to wood beams in terms of strength?

- Steel I-beams are significantly stronger than wood beams. Steel has a much higher tensile strength and rigidity, making it able to bear heavier loads and withstand bending or warping better than wood. Additionally, steel I-beams have a uniform and predictable strength, while wood beams can vary in strength due to natural defects and variations in grain direction. Overall, steel I-beams are a more reliable and sturdy choice for structural applications.

- Q: What are the different types of connections used for steel I-beams?

- There are several different types of connections used for steel I-beams, depending on the specific application and structural requirements. Some common types of connections include: 1. Welded Connections: This is the most common and widely used type of connection for steel I-beams. It involves welding the I-beam to a connection plate or another beam to create a strong and durable joint. 2. Bolted Connections: Bolted connections are another common method used to connect steel I-beams. This involves using bolts and nuts to fasten the beams together. Bolted connections can be easily adjusted or dismantled if needed, making them a flexible option. 3. Riveted Connections: Riveted connections were historically used but are less common nowadays. This method involves using rivets, which are metal pins with a formed head on one end, to connect the I-beams. Riveted connections provide high strength and durability. 4. Pinned Connections: Pinned connections allow for rotational movement between the connected beams. This type of connection is often used in structures where flexibility is required, such as bridges or seismic-resistant buildings. Pinned connections typically use pins or bearings to allow rotation. 5. Moment Connections: Moment connections are designed to transfer both vertical and horizontal loads between beams. These connections are used in structures where a rigid connection is required to resist bending moments. Moment connections can be achieved through welding or bolting, and they provide high strength and stability. It's important to note that the choice of connection type depends on factors such as load requirements, structural design, and construction methods. Consulting with a structural engineer or a qualified professional is crucial to ensure the appropriate connection type is chosen for specific applications.

- Q: Are steel I-beams suitable for modular construction?

- Indeed, steel I-beams prove to be a fitting option for modular construction. Their impressive structural attributes render them a prime selection for bearing substantial burdens and spanning extensive distances within modular edifices. Steel I-beams possess advantageous strength-to-weight ratios, enabling resourceful material utilization whilst upholding structural soundness. Furthermore, they offer exceptional resilience against bending, an imperative aspect in guaranteeing the steadfastness and longevity of modular frameworks. Moreover, steel I-beams exhibit high durability, fire resistance, and the ability to endure severe weather conditions, thereby qualifying them for a plethora of modular construction applications.

- Q: Are steel I-beams resistant to corrosion?

- Yes, steel I-beams are highly resistant to corrosion. They are typically made from a type of steel known as carbon steel, which contains a high amount of carbon and other elements that enhance its corrosion resistance. Additionally, steel I-beams can be further protected from corrosion by applying coatings such as galvanization or painting. These coatings create a barrier between the steel surface and the surrounding environment, preventing moisture and other corrosive elements from coming into direct contact with the steel. As a result, steel I-beams are commonly used in construction projects where corrosion resistance is essential, such as in the construction of bridges, buildings, and other structures exposed to harsh environments.

- Q: How do steel I-beams contribute to energy efficiency in buildings?

- Steel I-beams contribute to energy efficiency in buildings in several ways. Firstly, steel is a highly durable material that can withstand heavy loads, allowing for the construction of larger and taller buildings. This enables the use of efficient building designs, such as open floor plans and large windows, which maximize natural light and ventilation, reducing the need for artificial lighting and HVAC systems. Additionally, steel I-beams have a high strength-to-weight ratio, meaning they can support heavier loads with less material compared to other building materials. This allows for the construction of lighter and more efficient structures, reducing the overall energy consumption during construction and minimizing the environmental impact. Moreover, steel I-beams can be fabricated off-site with precision, reducing construction time and minimizing waste. This streamlined construction process further contributes to energy efficiency by reducing the energy required for on-site activities and minimizing construction-related carbon emissions. Lastly, steel is a recyclable material, and steel I-beams can be easily salvaged and reused in other construction projects. This promotes sustainability by reducing the demand for new steel production, which is an energy-intensive process. Overall, the use of steel I-beams in building construction enhances energy efficiency through their durability, lightweight nature, efficient fabrication process, and recyclability.

- Q: What are the different types of steel coatings available for I-beams in renovations?

- There are several different types of steel coatings available for I-beams in renovations, each with its own unique properties and benefits. Some of the most commonly used coatings include: 1. Galvanized Coating: Galvanized coating involves applying a layer of zinc to the surface of the I-beam. This coating provides excellent corrosion resistance, making it ideal for applications where the I-beams may be exposed to moisture or harsh environments. Galvanized coatings also offer good paint adhesion, which allows for additional decorative or protective coatings to be applied if desired. 2. Epoxy Coating: Epoxy coatings are a popular choice for I-beams in renovations due to their high resistance to chemicals, abrasion, and corrosion. These coatings are typically applied in multiple layers and require proper surface preparation for optimal adhesion. Epoxy coatings also offer excellent durability and can provide a smooth and glossy finish. 3. Polyurethane Coating: Polyurethane coatings are known for their exceptional resistance to UV radiation, making them an ideal choice for I-beams that will be exposed to sunlight or outdoor elements. These coatings provide excellent protection against corrosion, abrasion, and chemical exposure. Polyurethane coatings are available in various finishes, including gloss, semi-gloss, or matte, allowing for different aesthetic preferences. 4. Powder Coating: Powder coating involves applying a dry powder to the surface of the I-beam, which is then baked to form a protective and decorative layer. This coating provides excellent durability, impact resistance, and color retention. Powder coatings are available in a wide range of colors and finishes, allowing for customization and aesthetic appeal. They also offer good resistance to corrosion and chemicals. 5. Fire-Resistant Coating: Fire-resistant coatings are specifically designed to protect steel structures, including I-beams, from the damaging effects of fire. These coatings form an insulating barrier that delays the spread of flames and helps to maintain the structural integrity of the steel. Fire-resistant coatings can be applied as a paint or spray and are often used in buildings where fire safety is a primary concern. It is important to consider the specific requirements of the renovation project and consult with a professional to determine the most suitable steel coating for I-beams. Factors such as the environment, desired aesthetic, and level of protection required will help determine the best coating option.

- Q: Are steel I-beams suitable for outdoor structures like pergolas or carports?

- Pergolas or carports, outdoor structures that require durability and the ability to withstand the elements, are indeed suitable for steel I-beams. Steel, a material highly resistant to weather and known for its durability, is perfect for such applications. I-beams, specifically, are recognized for their strength and capacity to bear heavy loads and endure strong winds, making them a dependable option for outdoor structures. Furthermore, steel I-beams can be easily tailored and built to meet specific design needs, ensuring stability and structural integrity. In conclusion, utilizing steel I-beams in outdoor structures like pergolas or carports is a sensible and trustworthy decision that guarantees years of strength and endurance.

- Q: What are the common design codes for steel I-beams?

- The common design codes for steel I-beams include the American Institute of Steel Construction (AISC) 360, Eurocode 3, and the British Standards Institution (BSI) BS 5950.

- Q: Are steel I-beams suitable for supporting rooftop helipads?

- Rooftop helipads can indeed be supported by steel I-beams. Renowned for their strength and ability to bear heavy loads, I-beams are perfectly suited for such structural purposes. Steel, a widely used construction material, boasts high tensile strength and durability, enabling it to withstand the weight and impact associated with helicopter landings and takeoffs. Moreover, steel I-beams can be customized and engineered to meet specific load requirements, ensuring the necessary support for a helipad. The popularity of steel I-beams in supporting rooftop helipads across a range of buildings and structures stems from their versatility and dependable nature.

- Q: What are the advantages of using painted steel I-beams?

- There are several advantages of using painted steel I-beams in construction projects. Firstly, the paint coating on the steel I-beams provides a protective barrier against corrosion and rust. Steel is vulnerable to oxidation when exposed to moisture and chemicals, but the paint acts as a shield, preventing contact between the metal and these elements. This extends the lifespan of the I-beams and reduces the need for frequent maintenance or replacement. Secondly, painted steel I-beams offer enhanced aesthetics to the overall structure. The paint can be customized to match the desired color scheme or architectural style, making the beams blend seamlessly with the surrounding elements. This allows for a more visually appealing and cohesive appearance, enhancing the overall appeal and value of the building. Furthermore, the application of paint on steel I-beams can also improve their visibility and safety. By using high-visibility paint, the beams become more noticeable in low-light conditions, increasing safety for workers and pedestrians. This is particularly beneficial in industrial or construction settings where heavy machinery or vehicles operate near these beams. Additionally, painted steel I-beams offer easier identification and labeling within a construction site. By assigning different colors or markings to specific beams, it becomes simpler to identify and track their location and purpose. This aids in the organization and efficiency of the construction project, reducing errors and saving time. Lastly, painted steel I-beams are cost-effective in the long run. While the initial investment may be slightly higher compared to unpainted beams, the added protection against corrosion and rust significantly reduces maintenance and repair costs over time. Additionally, the enhanced durability of the painted beams ensures a longer lifespan, minimizing the need for replacement or repairs. In conclusion, the advantages of using painted steel I-beams include corrosion protection, enhanced aesthetics, improved visibility and safety, easier identification, and long-term cost savings. These benefits make painted steel I-beams a popular choice in various construction applications.

Send your message to us

Steel IPE Heavy Weight I Beam in Europe Standard En10025 S235JR

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords