Steel H Beam Profile with High Quality Structural Hot Rolled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Steel H Beam Profile with High Quality Structural Hot Rolled

1. Standard: GB700-88, Q235B2.

2. Grade: Q235, SS400 or Equivalent

3. Length: 6m,10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Usage & Applications of Steel H Beam Profile with High Quality Structural Hot Rolled

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure. etc.

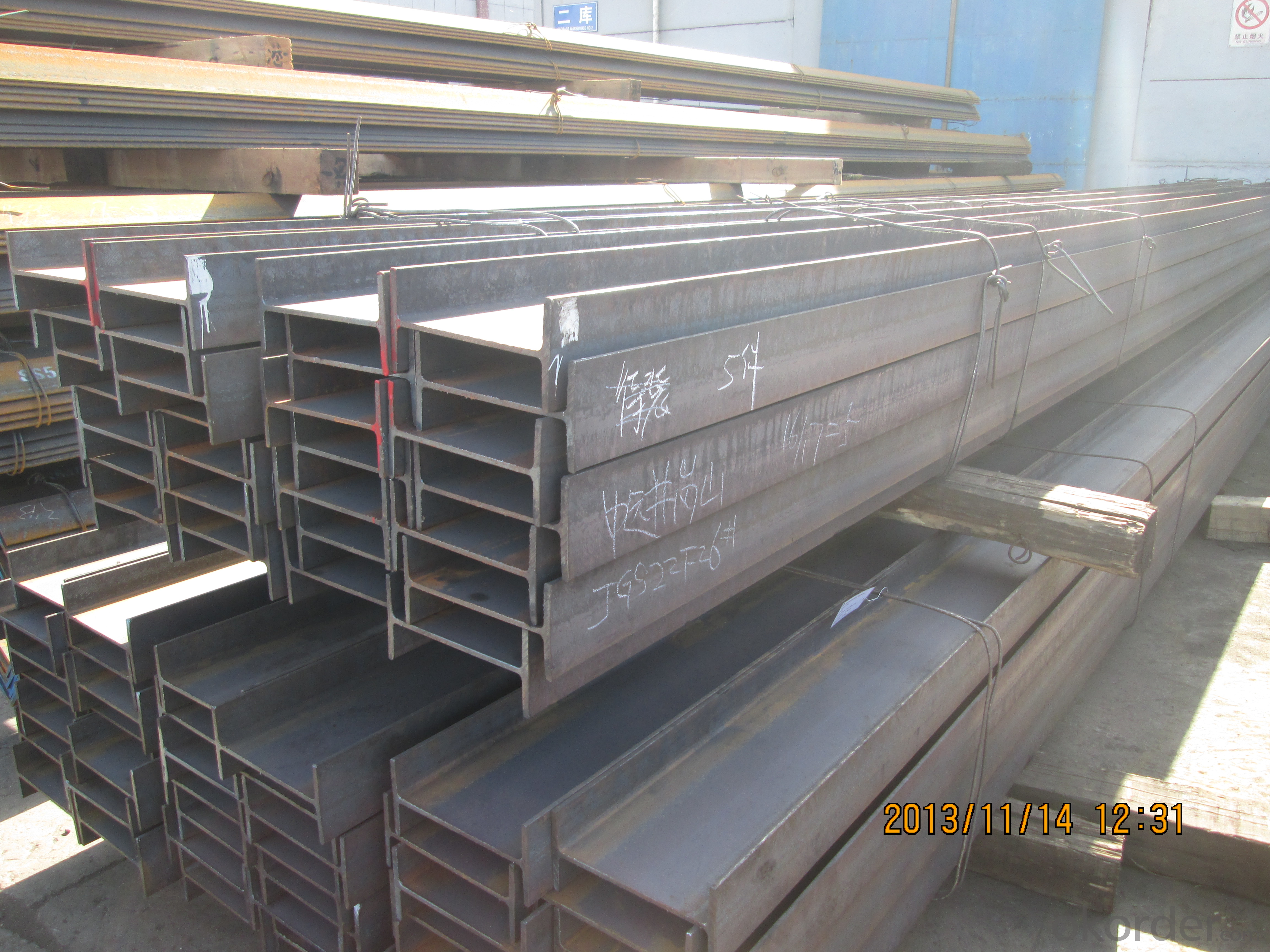

Packaging & Delivery of Steel H Beam Profile with High Quality Structural Hot Rolled

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Steel H Beam Profile with High Quality Structural Hot Rolled

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Images

- Q: Are steel H-beams resistant to pests and insects?

- Steel H-beams possess exceptional resistance against pests and insects. In contrast to wooden beams, which are susceptible to termites, ants, and various other pests, steel beams do not offer nourishment or shelter to these creatures. Furthermore, steel beams remain unaffected by rot or decay, thereby eradicating the possibility of harm caused by wood-boring insects. Consequently, steel H-beams emerge as a superb option for construction endeavors undertaken in regions susceptible to infestations by pests.

- Q: What is the theoretical weight of welded H - section steel 900*350*20*30?

- H steel is mainly used in engineering, plant, equipment, machinery and equipment, bridges, highways, houses, etc., with good mechanical and physical properties, firm and energy-saving and environmental protection. H steel is an economical section steel, widely used in industry, construction, bridge, oil drilling and so on

- Q: How do you calculate the moment capacity of steel H-beams?

- In order to determine the moment capacity of steel H-beams, it is necessary to take into account various properties of the beam, including its dimensions and material properties. The moment capacity, also referred to as the bending strength or flexural strength, is a measure of the beam's ability to withstand bending forces. To calculate the moment capacity of a steel H-beam, the following steps can be followed: 1. Calculate the section properties: The initial step involves determining the section properties of the H-beam, such as the moment of inertia (I) and the section modulus (Z). These properties are dependent on the dimensions of the beam, including the flange width, flange thickness, web height, and web thickness. These values can be obtained from structural design manuals or the specifications provided by the manufacturer. 2. Determine the yield strength: The subsequent step is to establish the yield strength (Fy) of the steel material used in the H-beam. This value represents the maximum stress that the steel can endure without experiencing permanent deformation. The yield strength can also be obtained from design manuals or the manufacturer's specifications. 3. Calculate the plastic moment capacity: The plastic moment capacity (Mp) is the maximum moment that the beam can withstand before it begins to yield or undergo plastic deformation. It is determined by multiplying the yield strength (Fy) by the section modulus (Z). The formula for calculating the plastic moment capacity is Mp = Fy * Z. 4. Determine the allowable moment capacity: The plastic moment capacity is not always the governing factor in design. Depending on the design requirements and safety factors, the allowable moment capacity may be lower than the plastic moment capacity. The allowable moment capacity is calculated by multiplying the plastic moment capacity by a factor of safety (Fs). The factor of safety takes into account uncertainties in materials, loads, and other design considerations. The formula for calculating the allowable moment capacity is Ma = Mp * Fs. By following these steps, one can ascertain the moment capacity of steel H-beams and ensure that the beam is designed to withstand the necessary bending forces in a safe and efficient manner. It is crucial to consult design codes, standards, and principles of structural engineering to guarantee the accuracy and reliability of the calculations.

- Q: How are steel H-beams manufactured?

- Hot rolling is the process used to manufacture steel H-beams. It begins with the selection of high-quality steel, usually in the form of a large billet. This billet is then heated to a temperature above its recrystallization point, typically around 1200 to 1300 degrees Celsius. Once the billet reaches the desired temperature, it is fed into a rolling mill. The mill consists of a series of rollers that gradually shape the heated billet into the H-beam profile. The rollers apply pressure to the billet, causing it to elongate and take on the desired shape. This is known as hot rolling because the steel is rolled while it is still hot and malleable. Throughout the rolling process, the billet is continuously passed through the rollers, undergoing multiple passes until it achieves the required dimensions and shape. The final profile of the H-beam is determined by the shape of the rollers, with each roller gradually shaping the steel. Once the rolling process is completed, the newly formed H-beams are cooled using either air or water. This cooling process is crucial to maintaining the steel's strength and structural integrity. After cooling, the H-beams are cut to the desired lengths and undergo any necessary further processing, such as surface treatment or galvanization. Finally, they are packaged and shipped to customers. In summary, the manufacturing of steel H-beams involves heating a billet to a high temperature, rolling it through a series of rollers to shape it, cooling it, and then further processing it. This process ensures the production of high-quality and structurally sound H-beams that are used in construction and engineering projects.

- Q: Model H is 580*280*12*14. How much is the theoretical weight of the steel?It's better to list the complete formula, thank you!

- Sectional area=(H+2T =(TW)2bt 580×2×14)+2×280×12×14 = 144.64cm2

- Q: What are the common uses of steel H-beams?

- Steel H-beams, also known as I-beams or W-beams, are widely used in construction and structural engineering due to their strength and versatility. Some of the common uses of steel H-beams include: 1. Structural support: H-beams are commonly used to provide structural support for buildings, bridges, and other structures. Their shape and design allow them to bear heavy loads and distribute weight evenly, making them ideal for supporting large structures. 2. Building frames: H-beams are often used as the main structural components in building frames. They can be easily connected together to form the skeleton of a building, providing stability and strength. 3. Bridge construction: Steel H-beams are widely used in the construction of bridges due to their ability to support heavy loads over long spans. They are often used as the main load-bearing beams in bridge superstructures, providing the necessary strength and durability. 4. Mezzanine floors: H-beams are commonly used in the construction of mezzanine floors, which are intermediate floors between the main floors of a building. These floors are often used to create additional storage space or office areas and require strong support structures, which H-beams provide. 5. Industrial structures: Steel H-beams are frequently used in the construction of industrial structures such as warehouses, factories, and manufacturing plants. These structures often require large open spaces and high load-bearing capacities, which H-beams can provide. 6. Support columns: H-beams are also used as support columns in various applications. Whether it is supporting roof structures, building facades, or heavy equipment, H-beams can offer the necessary strength and stability. 7. Piling: H-beams are commonly used in piling applications, where they are driven into the ground to provide foundational support for structures such as bridges, buildings, and retaining walls. They help distribute the weight of these structures and prevent settling or shifting. In summary, steel H-beams are widely used in construction and structural engineering for their strength, versatility, and ability to support heavy loads. They are commonly used in building frames, bridges, mezzanine floors, industrial structures, support columns, and piling applications.

- Q: Can Steel H-Beams be used in convention center or exhibition hall construction?

- Yes, Steel H-Beams can be used in convention center or exhibition hall construction. They are commonly used in such projects due to their high strength, durability, and ability to support heavy loads. Steel H-Beams provide structural integrity and can be easily fabricated and installed, making them a reliable choice for large-scale construction projects like convention centers and exhibition halls.

- Q: How do Steel H-Beams perform in seismic or high-wind conditions?

- Steel H-Beams are known for their excellent performance in seismic or high-wind conditions. Due to their strong structural integrity and flexibility, they can effectively absorb and distribute forces generated by earthquakes or strong winds. This makes them highly resistant to damage and deformation, ensuring the safety and stability of buildings and structures in such conditions.

- Q: How do steel H-beams contribute to natural ventilation in buildings?

- Steel H-beams do not directly contribute to natural ventilation in buildings. However, they play an important role in the structural framework of the building, allowing for open and spacious designs that can incorporate elements like large windows, skylights, or operable vents. These architectural features, combined with proper building orientation and design, can enhance natural ventilation by allowing for the flow of fresh air and the expulsion of stale air, promoting a healthier and more comfortable indoor environment.

- Q: Can steel H-beams be used for residential extensions or additions?

- Yes, steel H-beams can be used for residential extensions or additions. They provide structural support and can be used to create open floor plans or support additional weight. Steel H-beams offer durability, versatility, and can be customized to fit specific project requirements.

Send your message to us

Steel H Beam Profile with High Quality Structural Hot Rolled

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords