Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantage of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

1.Prime quality

2.Competitive price

3.Professional service

4.Prompt delivery & Seaworthy packing

5.Mill Test Certificate

Specification of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

Material: Q235; A36; SS400; ST37; SAE1006/1008; S275JR; Q345,S355JR; 16Mn; ST52 etc.

thickness: 3-30mm, width 10-400mm, length 5-12M

Length: fixed length, random length

Application of Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

Household Appliance | Refrigerator shutter &side panels, Rice Cooker, Washer, Microwave Ovens, Freezers, Air conditions, Water Heaters, Sterilization Cabinets, Range Hoods, Computer Panels , DVD/DVB panels, TV back panel etc. |

Construction Material | Fireproof Door &Kitchen Cabinet ,Ceiling, Sanitary Unit, Elevator etc. |

Transportation | Car, Ship, Trains, Aircraft Equipment. etc. |

Education and Health Field | Electronic Writing Boards, Projection Screens, Clean Operating Rooms, etc. |

A)Features of Stainless Steel Flat Bar:

a) The appearance of cold-rolled products gloss is good, beautiful;

b) Excellent high temperature strength;

c) Excellent work-hardening (after processing weakly magnetic)

d) Non-magnetic state solution.

B)Specifications of Stainless Steel Flat Bar:

1. Standard: GB ASTM, JIS, etc.

2. Grade: 200,300,400series

3. Size: 3mm*19mm ~ 12mm*140mm

4. Thickness: from 3mm to 12mm

5. Width: from 19mm to 140mm

6. Shape Manufactured: flat bar

7. Length: 2-6m or as customers' request

8. Surface finish: Black & Pickled & Bright

9. Manufacture technology: cold drawn/cold rolled/hot rolled

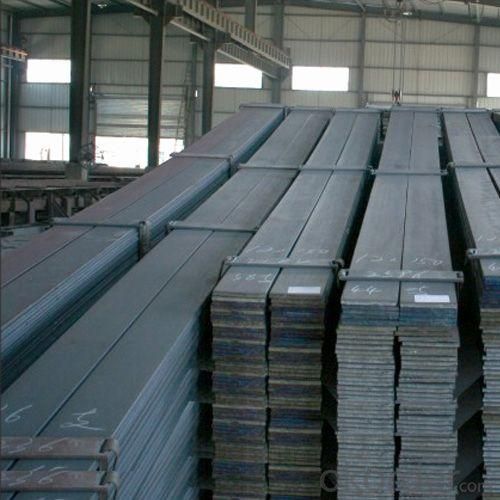

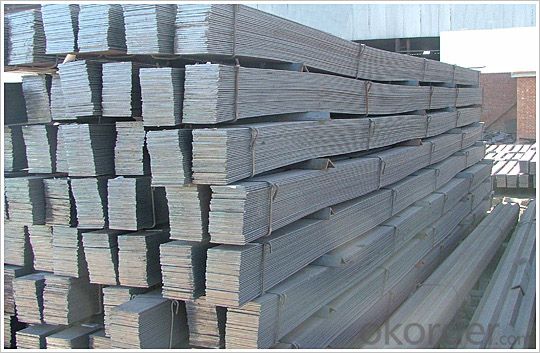

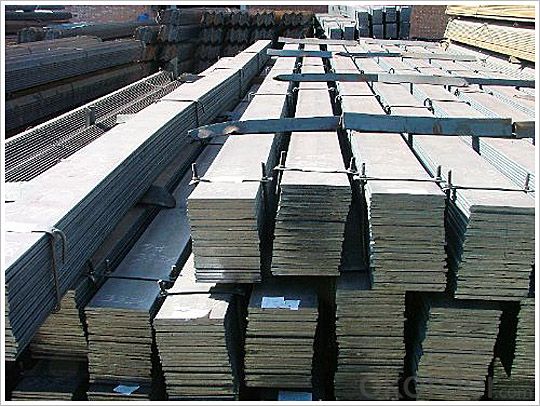

C) Product Photos

- Q: Are steel flat bars suitable for structural applications?

- Yes, steel flat bars are suitable for structural applications. They are widely used in the construction industry to provide support and stability in various structures such as buildings, bridges, and frameworks. Steel flat bars offer high strength, durability, and resistance to bending and deformation, making them an ideal choice for structural applications.

- Q: What are the different surface finishes available for steel flat bars?

- There are several different surface finishes available for steel flat bars, each offering unique properties and aesthetic appeal. 1. Hot rolled finish: This is the most common surface finish for steel flat bars. It is achieved by heating the steel above its recrystallization temperature and then rolling it to form the desired shape. The hot rolled finish has a rough and scaled texture, making it suitable for applications where appearance is not a primary concern. 2. Cold drawn finish: In this process, the steel flat bar is pulled through a die to reduce its thickness and improve its surface finish. Cold drawn bars have a smooth and polished surface, making them ideal for applications where a clean and sleek appearance is desired. 3. Bright finish: This surface finish is achieved by further polishing the cold drawn bars to give them a high-gloss shine. Bright finish steel flat bars are often used in decorative applications, such as handrails, furniture, and architectural elements, where a reflective and aesthetically pleasing surface is desired. 4. Galvanized finish: Galvanizing is a process in which a layer of zinc is applied to the steel flat bar to protect it from corrosion. The galvanized finish provides excellent durability and resistance to rust, making it suitable for outdoor applications or environments with high moisture content. 5. Coated finishes: Steel flat bars can also be coated with various materials to enhance their appearance or provide additional protection. Common coatings include powder coating, which provides a durable and decorative finish, and epoxy coating, which offers increased resistance to chemicals and abrasion. Ultimately, the choice of surface finish for steel flat bars depends on the specific requirements of the application, including factors such as aesthetics, corrosion resistance, and durability.

- Q: Can steel flat bars be used for making frames or supports for signs?

- Frames or supports for signs can indeed be made using steel flat bars. These bars possess both versatility and strength, which makes them excellent for providing structural support. Custom frames of different shapes and sizes can be easily crafted by cutting, bending, and welding these bars. Steel's robust nature allows it to withstand harsh weather conditions, making it suitable for outdoor applications and ensuring long-lasting durability. Moreover, to enhance their aesthetic appeal and protect against corrosion, steel flat bars can be painted or coated. All in all, due to their strength, versatility, and ability to withstand various environmental factors, steel flat bars are widely chosen for constructing frames or supports for signs.

- Q: Can steel flat bars be used in the construction of buildings?

- Indeed, buildings can be constructed using steel flat bars. Owing to their robustness, endurance, and adaptability, steel flat bars are frequently employed in construction. They offer structural reinforcement and are commonly utilized for framing, reinforcement, and support systems within buildings. Steel flat bars can be conveniently fashioned, welded, and molded to fulfill the precise demands of a construction endeavor. Furthermore, they possess resistance against corrosion, fire, and pests, rendering them an excellent option for constructing enduring and robust buildings.

- Q: Are steel flat bars suitable for architectural cladding?

- Yes, steel flat bars can be suitable for architectural cladding. Steel is a popular material choice for cladding due to its durability, strength, and versatility. Steel flat bars can be used to create sleek and modern designs for architectural cladding applications. They can be easily shaped, cut, and welded to achieve the desired look and can be finished with various surface treatments such as galvanizing, powder coating, or painting to enhance their aesthetic appeal and protect against corrosion. Steel flat bars can be used as vertical or horizontal elements in cladding systems, providing structural support and creating visually appealing facades. Additionally, steel is a sustainable material that can be recycled, making it an environmentally friendly choice for architectural cladding. However, it is important to consider the specific requirements of the project, such as the local climate conditions, maintenance requirements, and the desired design aesthetic, to determine if steel flat bars are the most suitable option for the specific architectural cladding application.

- Q: Can steel flat bars be used for manufacturing tools or machinery?

- Manufacturing tools or machinery is indeed possible with steel flat bars. Steel, being a highly versatile and durable material, is apt for a wide array of applications. Due to their strength, rigidity, and capacity to withstand heavy loads and pressure, steel flat bars are commonly employed in the manufacturing industry. They can be easily shaped, welded, and machined to fabricate diverse components and parts for tools and machinery. Moreover, steel flat bars are renowned for their exceptional resistance to corrosion, a vital factor for ensuring the durability and dependability of tools and machinery. All in all, steel flat bars are a favored choice in the manufacturing industry, thanks to their reliability, versatility, and suitability for producing top-notch tools and machinery.

- Q: Can steel flat bars be galvanized or coated with zinc?

- Yes, steel flat bars can be galvanized or coated with zinc. Galvanization or zinc coating is a common method used to protect steel from corrosion. It involves immersing the steel in a bath of molten zinc or applying a zinc coating onto the surface of the steel. This process creates a protective layer of zinc that acts as a barrier against rust and other forms of corrosion. Galvanized steel flat bars are widely used in various industries, including construction, infrastructure, and manufacturing, due to their enhanced durability and resistance to corrosion.

- Q: Is the laying of a 40X4 flat steel for fire fighting metal trunking?

- Without laying, the cable bridge, each section of the joint, there is a copper wire to prepare flat belt connected, it is bridge grounding jumper cable.

- Q: Are steel flat bars resistant to fire?

- Generally, steel flat bars are resistant to fire. Steel, being a non-combustible material, does not burn or aid in the spread of fire. Due to its high melting point and excellent heat resistance, steel is highly resistant to fire. As a result, steel flat bars are commonly used in construction, manufacturing, and industrial settings where fire resistance is necessary. However, it is important to remember that while steel itself is fire-resistant, other materials attached to or surrounding the steel bars may not be. Therefore, it is crucial to consider the entire system and ensure that all components are fire-resistant to provide maximum fire protection.

- Q: Can steel flat bars be used for staircases?

- Yes, steel flat bars can be used for staircases. Steel flat bars are commonly used in construction for various applications, including staircases. They are strong, durable, and can support heavy loads, making them suitable for staircase construction. Steel flat bars can be used as stringers, which are the main structural supports for the stairs, or as treads and risers, which are the steps themselves. They can be welded or bolted together to create a sturdy and stable staircase. Additionally, steel flat bars can be customized and fabricated to fit specific design requirements and dimensions, making them a versatile choice for staircase construction.

Send your message to us

Steel Flat Bar ISO and SGS Certificate Cold Rolled Flat Bars

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords