Stainless Steel Sheet with 321 grade 2B in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

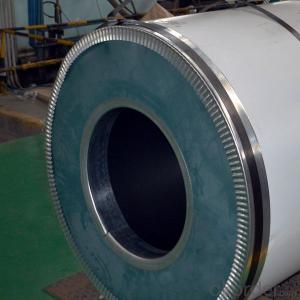

stainless steel sheet with 321 grade 2B

Features:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information:

1. Steel grade: 321

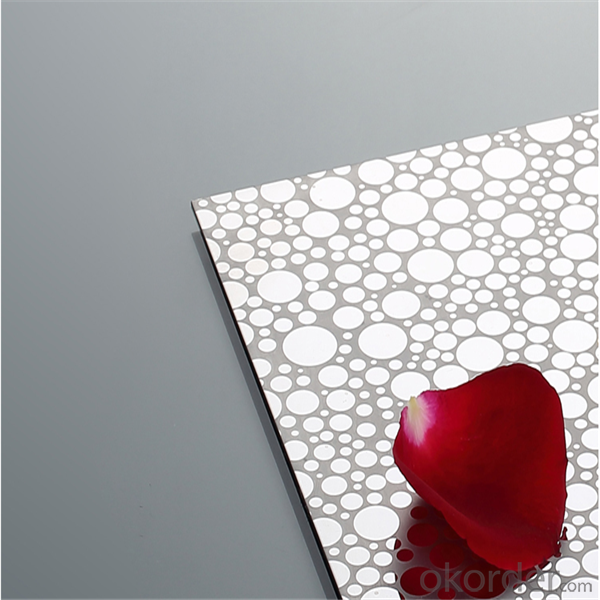

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

9. Advantage: Colorful, showing the splendor of your quality, wear-resistant as well, strong corrosion resistance, anti-rust property and decorative effect, durable and beautiful in good taste.

10. Supplier Product Code: SDJM

11. Competitive Advantages of the product

1) Stainless Steel Decorative Sheet

2) Customize pattern and color coating

3) Advantage: Various patterns, splendid decorative effect, fashionable design

4) Surface finish: Mirror, 2b, no.1, no.4, 6k, 8k, polished, etc

Item | stainless steel plate(Hot rolled,cold rolled) |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

Material | 310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L, 302,301,201,202,403,405,409,409L,410,410S,420,430,631,904L,Duplex,etc |

Surface | 2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,checkered,embossed,hair line,sand blast,Brush,etching,etc |

Thickness | 0.01~200mm |

Width | 1000mm,1219mm,1500mm,1800mm,2000mm,2500mm,3000mm,3500mm,etc |

Length | 2000mm,2440mm,3000mm,5800mm,6000mm,etc |

Package | Standard export package,suit for all kinds of transport,or as required. |

Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High) 40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High) 40ft HC:12032mm(Lengh)x2352mm(Width)x2698mm(High) |

Price term | Ex-Work,FOB,CNF,CFR,CIF,FCA,DDP,DDU,etc |

Payment term | TT,L/C,western Union |

Export to | Ireland,Singapore,Indonesia,Ukraine,Saudi Arabia,Spain,Canada,USA,Brazil,Thailand,Korea,Iran, India,Egypt,Oman,Malaysia,Bangladesh,Dubai,Viet Nam,Kuwait,Peru,Mexico,Russia,etc |

MOQ | 500Kg |

Application | Stainless steel plate applies to construction field, ships building industry, petroleum,chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.Stainless steel plate can be made according to the customers requirements. |

Contact | If you have any question,please feel free to contact me . we are sure your inquiry or requirements will get prompt attention |

- Q: Are stainless steel sheets suitable for elevator handrails?

- Yes, stainless steel sheets are suitable for elevator handrails. Stainless steel is a popular choice for handrails in elevators due to its durability, corrosion resistance, and aesthetic appeal. Elevator handrails are subject to constant use and exposure to various environmental factors, such as moisture and fingerprints. Stainless steel is highly resistant to corrosion, ensuring the longevity and maintenance-free operation of the handrails. Additionally, stainless steel has a sleek and modern appearance that complements the overall design of elevators. Its smooth surface is easy to clean and maintain, making it a hygienic choice for handrails in public spaces. Overall, stainless steel sheets are an excellent material choice for elevator handrails.

- Q: What is the maximum temperature that stainless steel sheets can withstand?

- The maximum temperature that stainless steel sheets can withstand depends on the specific grade or alloy of stainless steel being used. However, most stainless steel sheets can typically withstand temperatures of up to around 1500 degrees Fahrenheit (815 degrees Celsius) before experiencing significant structural or mechanical changes.

- Q: How do you attach stainless steel sheets to a wall?

- To attach stainless steel sheets to a wall, you can use a combination of adhesive and mechanical fasteners. First, ensure that the wall is clean and free from any debris or grease. Apply a strong construction adhesive to the back of the stainless steel sheet, spreading it evenly across the surface. Then, press the sheet firmly against the wall and hold it in place for a few minutes to allow the adhesive to bond. Additionally, use mechanical fasteners such as screws or nails to secure the stainless steel sheet to the wall, placing them along the edges and in the center of the sheet for added support and stability.

- Q: 304 stainless steel plate price ups and downs affected by what factors?

- First of all, the stainless steel ingredients, that is, stainless steel raw materials. Stainless steel is a kind of high alloy steel can resist corrosion in air or chemical corrosive medium. His representative steel 13 steel 1Cr17 (430) and 18- Ocr18Ni9 chromium nickel, stainless steel is the main raw material of iron, chromium, nickel, Cr NI, the price of raw materials has decisive effect on the price of stainless steel to the rising prices of raw materials, to support the formation of stainless steel prices, anti pressure, or become power. So we need to pay attention to the stainless steel market, we must pay close attention to the global price of nickel, especially LME nickel price trend, but also on the global iron ore, molybdenum price trend and the latest developments, and other non-ferrous metal prices.

- Q: Can stainless steel sheets be used in food processing?

- Food processing can make use of stainless steel sheets. They are commonly chosen in the food industry because of their advantageous properties. One crucial property is their resistance to corrosion, which is highly important in food processing environments where contact with water, chemicals, and food is frequent. Stainless steel sheets are also non-reactive, meaning they do not interact with food or impact its taste, thus making them a safe option for food processing equipment. Moreover, stainless steel is easy to clean and maintain, making it ideal for maintaining the high levels of hygiene required in food processing facilities. Its durability and strength ensure that it can withstand the demanding nature of food processing operations. Overall, stainless steel sheets are the preferred choice in the food industry for their suitability in food processing applications.

- Q: Can stainless steel sheets be used for magnetic shielding?

- Yes, stainless steel sheets can be used for magnetic shielding to some extent. While stainless steel is not inherently magnetic, it does have some magnetic properties. Stainless steel alloys contain iron, a magnetic material, which allows them to exhibit weak magnetic characteristics. However, the magnetic shielding effectiveness of stainless steel sheets is limited compared to other materials specifically designed for magnetic shielding, such as mu-metal or nickel-iron alloys. These materials have a higher permeability, meaning they can redirect and absorb magnetic fields more effectively than stainless steel. Nonetheless, stainless steel sheets can still provide some level of magnetic shielding, especially in lower intensity magnetic fields. They can help reduce the transmission of magnetic fields from one area to another, which might be useful in certain applications. However, for high-intensity or sensitive magnetic shielding requirements, it is recommended to use specialized magnetic shielding materials for optimum effectiveness.

- Q: How long do stainless steel sheets last?

- Stainless steel sheets have an exceptionally long lifespan and can last for several decades or even a lifetime with proper care and maintenance.

- Q: Can stainless steel sheets be used for outdoor signage?

- Indeed, outdoor signage can be made using stainless steel sheets. This material, known for its durability and resistance to corrosion, remains unscathed in challenging weather conditions while preserving its visual appeal. Its widespread use in outdoor signage can be attributed to its ability to withstand rust, fading, and harm caused by sunlight, rain, snow, and other environmental factors. Moreover, stainless steel sheets can be personalized with different finishes like brushed or polished, enhancing their aesthetic allure and making them suitable for any outdoor signage requirement.

- Q: What is the weight of stainless steel sheets?

- The weight of stainless steel sheets may differ based on their thickness and dimensions. Typically, stainless steel sheets possess a density of 8 grams per cubic centimeter. To determine the weight of a stainless steel sheet, one must acquire the dimensions (length, width, and thickness) and multiply them to ascertain the volume. Subsequently, the weight can be determined by multiplying the volume by the density.

- Q: What are the common manufacturing standards for stainless steel sheets?

- There are several common manufacturing standards for stainless steel sheets that ensure their quality and consistency. One of the most widely recognized standards is the ASTM International (formerly known as the American Society for Testing and Materials) standard. ASTM A240 is the specific standard for stainless steel sheets, which specifies the requirements for chemical composition, mechanical properties, and other relevant characteristics of the material. Another important manufacturing standard is the EN (European Norm) standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers various aspects such as dimensions, tolerances, surface finishes, and more. Additionally, there are national standards developed by different countries. For example, in Japan, the Japanese Industrial Standards (JIS) classify stainless steel sheets under various specifications such as JIS G4304 and JIS G4305. These standards define the requirements for chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) also sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in the manufacturing of stainless steel sheets, and their properties are defined by the AISI. It is important for manufacturers and suppliers to adhere to these standards to ensure that the stainless steel sheets meet the desired quality requirements and can be used reliably in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across different industries.

Send your message to us

Stainless Steel Sheet with 321 grade 2B in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords