Stainless Steel Sheet POSCO LISCO ZPSS TISCO

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Stainless Steel Sheet POSCO LISCO ZPSS TISCO

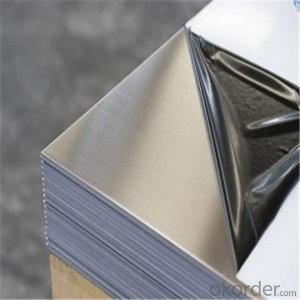

| Name | Stainless Steel Sheet POSCO LISCO ZPSS TISCO |

| Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

| Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | 0.2mm-150mm |

| Width | 1000,1219,1250,1500mm,?or as your requirements |

| Length | 2000,2438,2500,3000,6000mm,?or as your requirements |

| Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

| Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

| Delivery Time | 5-7 days after confirming the order |

| MOQ | 1 Ton |

| Payment Terms | 30% deposit by T/T, the balance should be paid off before delivery |

Stainless Steel Sheet POSCO LISCO ZPSS TISCO

4.Hot rolled stainless steel plate

Thickness : 3.0mm-120mm

Width : 1219mm/1500mm/1800mm/2000mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 3.0mm-120mm(TK)*1219mm(W)*2438mm(L)

3.0mm-120mm(TK )*1500mm(W)*6000mm(L)

3.0mm-120mm(TK) *1800mm(W)*6000mm(L)

3.0mm-120mm(TK) *2000mm(W)*6000mm(L)

Surface : No.1

Stainless Steel Sheet POSCO LISCO ZPSS TISCO

5.Characteristics and application

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

5.Payment : Usually 30% of the amount by T/T as deposit , and the balance money shall be paid by T/T after got the faxed B/L.Or L/C at sight .

6. Package: Kraft paper+Hard board+metal/wooden pallet+metal strip; or based on the customer requirement.

7. USE: construction.machinebuilding,container manufacturing,shipbuilding,bridges and so on.

The operating philosophy of our company : high quality and best service and competitive price and prompt delivery .We sincerely welcome the old and new customers to inquiry the price . any questions and needs you have , pls don't hesitate to contact us anytime .

- Q: Can stainless steel sheets be used for fireplaces?

- Yes, stainless steel sheets can be used for fireplaces. Stainless steel is a popular material choice for fireplaces due to its high heat resistance and durability. It can withstand the high temperatures generated by the fire without warping or melting, making it a safe and reliable option. Stainless steel sheets can be used to construct the interior of the fireplace, including the firebox and chimney, or can be used as a decorative element on the façade of the fireplace. Additionally, stainless steel is resistant to corrosion and rust, ensuring that the fireplace will maintain its appearance over time.

- Q: Can stainless steel sheets be used for air conditioning systems?

- Yes, stainless steel sheets can be used for air conditioning systems. Stainless steel is a durable and corrosion-resistant material, making it suitable for use in air conditioning systems where it may be exposed to moisture and varying temperatures. Additionally, stainless steel's high strength-to-weight ratio makes it ideal for constructing components such as ductwork, evaporator coils, and heat exchangers in air conditioning systems.

- Q: How do you prevent fingerprints on stainless steel sheets?

- There are several steps you can take to prevent fingerprints on stainless steel sheets: 1. Start by thoroughly cleaning the surface of the stainless steel sheets using a mild detergent or stainless steel cleaner. This will eliminate any existing fingerprints or smudges. 2. When handling the sheets, wear gloves to avoid transferring natural oils from your hands onto the surface. Cotton or nitrile gloves are recommended as they offer a good grip and leave no residue. 3. Minimize direct contact with the stainless steel surface as much as possible. This can be achieved by using specialized tools or wearing gloves when handling and installing the sheets. 4. Consider applying a protective coating specifically designed for stainless steel. These coatings create a barrier that repels fingerprints and simplifies the cleaning process. Be sure to follow the manufacturer's instructions for proper application. 5. Use a soft microfiber cloth when cleaning the stainless steel sheets. Microfiber is gentle on the surface and helps prevent streaks and fingerprints. Avoid using abrasive materials or rough scrubbers that can damage the stainless steel finish. 6. Establish a regular cleaning routine to remove any fingerprints or smudges that may appear over time. Dilute a mild detergent in warm water and use a soft cloth or sponge to wipe down the stainless steel sheets. Rinse with clean water and thoroughly dry. By following these preventive measures and cleaning techniques, you can significantly reduce the visibility of fingerprints on stainless steel sheets and keep them looking clean and flawless.

- Q: Can stainless steel sheets be used for elevator flooring?

- Yes, stainless steel sheets can be used for elevator flooring. Stainless steel is a popular choice for elevator flooring due to its durability, strength, and resistance to corrosion. It is able to withstand heavy foot traffic and is easy to clean and maintain. Additionally, stainless steel is visually appealing and can add a sleek and modern look to elevators.

- Q: Can stainless steel sheets be used for countertops?

- Yes, stainless steel sheets can be used for countertops. Stainless steel is a durable and versatile material that is resistant to stains, heat, and bacteria, making it an excellent choice for kitchen countertops. It is easy to clean, maintain, and has a sleek and modern appearance. Stainless steel countertops are commonly used in commercial kitchens but are also becoming increasingly popular in residential settings due to their durability and hygienic properties.

- Q: What is the weldability of stainless steel sheets?

- Stainless steel sheets have good weldability due to their composition and properties. They can be easily welded using various welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. However, the specific weldability may vary depending on the grade and thickness of the stainless steel sheet. It is important to use appropriate welding procedures and techniques to ensure a strong and durable weld.

- Q: What is the ductility of stainless steel sheets?

- The ductility of stainless steel sheets refers to its ability to deform under tensile stress without fracturing or breaking. Stainless steel is known for its excellent ductility, allowing it to be stretched, bent, or hammered into various shapes without losing its structural integrity. This property makes stainless steel sheets highly versatile and suitable for a wide range of applications, including construction, automotive manufacturing, and kitchen appliances. Due to its high ductility, stainless steel can be formed into complex shapes or rolled into thin sheets, making it ideal for intricate designs or thin-walled structures. Additionally, stainless steel's ductility also allows for easy welding, making it a popular choice for fabrication processes.

- Q: Are stainless steel sheets resistant to intergranular corrosion?

- Yes, stainless steel sheets are generally resistant to intergranular corrosion. This is because stainless steel contains a high percentage of chromium, which forms a protective oxide layer on the surface of the metal. This oxide layer acts as a barrier, preventing the metal from coming into contact with corrosive elements in the environment. However, in certain conditions, such as exposure to high temperatures or welding processes, the chromium in stainless steel can be depleted, leading to the formation of chromium carbides at the grain boundaries. This can result in intergranular corrosion, also known as sensitization. To mitigate this, stainless steel sheets can be treated through a process called stabilization, which involves adding elements like titanium or niobium to the steel to bind with the carbon and prevent the formation of chromium carbides. Overall, stainless steel sheets are highly resistant to intergranular corrosion, but precautions should be taken in specific situations to maintain their corrosion-resistant properties.

- Q: What are the different types of finishes available for stainless steel sheets?

- There are several different types of finishes available for stainless steel sheets, each offering its own unique appearance and level of protection. Some of the most common finishes include: 1. No. 1 Finish: This is a dull, rough, and non-reflective finish that is achieved by hot rolling the stainless steel sheet. It is commonly used for industrial applications where appearance is not a primary concern. 2. No. 2B Finish: This finish is a smooth, reflective surface achieved by cold rolling the stainless steel sheet and then annealing it in a controlled atmosphere. It is widely used in applications that require a visually appealing finish, such as kitchen appliances and decorative trim. 3. No. 4 Finish: Also known as brushed or satin finish, this is achieved by applying a series of abrasive grits to the surface of the stainless steel sheet. It creates a uniform, linear grain pattern that is commonly used for architectural and decorative purposes. 4. No. 8 Finish: This is a highly reflective finish that is achieved by polishing the stainless steel sheet to a mirror-like appearance. It is often used in applications where a sleek and sophisticated look is desired, such as in high-end architectural projects and automotive trim. 5. BA (Bright Annealed) Finish: This finish is achieved by annealing the stainless steel sheet in a controlled atmosphere and then pickling or blasting it to remove any oxide scale. It results in a smooth, bright surface that is commonly used in applications that require optimum corrosion resistance, such as medical equipment and pharmaceutical processing. 6. Hairline Finish: This finish is achieved by mechanically brushing the surface of the stainless steel sheet with fine abrasive belts. It creates a subtle, textured look that can be used for architectural and decorative purposes. 7. Embossed Finish: This finish involves imprinting a raised or recessed pattern onto the surface of the stainless steel sheet using a rolling mill or press. It adds texture and visual interest to the sheet and is often used in applications such as elevator interiors, wall cladding, and signage. These are just a few of the many finishes available for stainless steel sheets, each offering its own unique aesthetic and functional properties. The choice of finish depends on the specific application and desired appearance.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

Send your message to us

Stainless Steel Sheet POSCO LISCO ZPSS TISCO

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords