Stainless Steel Sheet/Plate 430 for Automobile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet/Plate 430 for Automobile

Description of Stainless Steel Sheet/Plate 430 for Automobile:

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series

stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the

excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Main Features of Stainless Steel Sheet/Plate 430 for Automobile:

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Specifications of Stainless Steel Sheet/Plate 430 for Automobile:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Surface Finish Characteristics Stainless Steel Sheet/Plate 430 for Automobile:

| Surface finish | Characteristics and application |

| 2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

| No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

| No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

| HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

| BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

| 8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

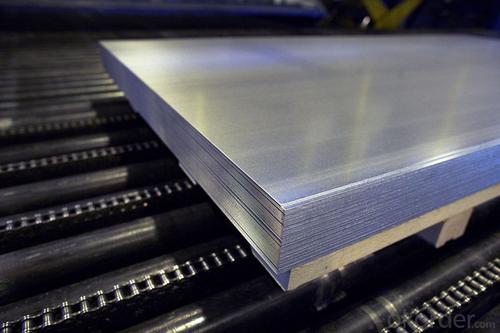

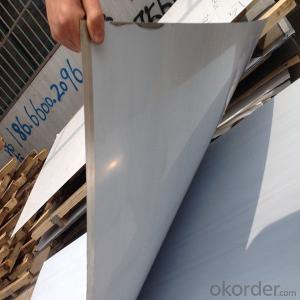

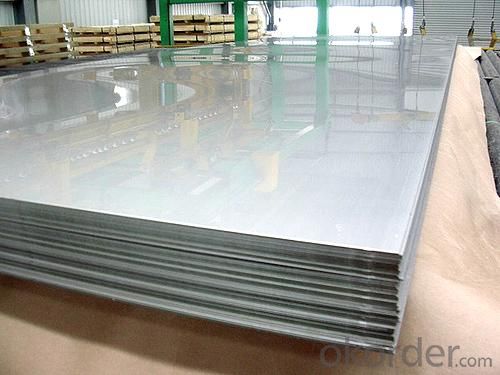

Images of Stainless Steel Sheet/Plate 430 for Automobile:

Sandard Seaworth Packing(wooden packing with water proof paper):

FAQ of Stainless Steel Sheet/Plate 430 for Automobile:

1. What are we supplying?

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently supplying grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321, 410/420/430/443/444/409L, and 904L.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: What are the different types of stainless steel sheet surface treatments available?

- There is a wide range of surface treatments available for stainless steel sheets, each with its own distinct benefits and appearances. Some of the most commonly used treatments are: 1. No.1 Finish: This finish is ideal for industrial purposes and is achieved through hot-rolling, annealing, and pickling. It has a rough texture with visible grain lines. 2. No.2B Finish: Also known as a bright, cold-rolled finish, this treatment provides a smooth and reflective surface with a moderate level of gloss. It is obtained through annealing and pickling. 3. No.3 Finish: By using progressively finer abrasive materials, a finely polished surface is achieved. It has a semi-reflective appearance and is often used for decorative applications. 4. No.4 Finish: Similar to the No.3 finish, but with a higher level of polish, this treatment gives the stainless steel sheet a satin-like appearance. It is commonly used in architectural and kitchen equipment applications. 5. BA (Bright Annealed) Finish: This treatment results in a mirror-like, highly reflective finish. It is achieved by annealing the stainless steel sheet in a controlled atmosphere and is often used for decorative purposes and in the production of household appliances. 6. Embossed Finish: This treatment involves stamping a pattern onto the stainless steel sheet to create a textured surface. It is frequently used for decorative purposes or to enhance grip on surfaces. 7. Colored Finish: Stainless steel sheets can also be treated with various colored coatings, such as gold, black, or bronze. These finishes are achieved through processes like PVD (Physical Vapor Deposition) or electroplating. Each surface treatment offers its own advantages and is suitable for specific applications. When selecting the appropriate treatment for a stainless steel sheet, it is important to consider factors such as durability, corrosion resistance, aesthetic appeal, and intended use.

- Q: Can stainless steel sheets be used in automotive industry?

- The automotive industry finds stainless steel sheets to be a valuable resource. This material has gained popularity due to its numerous advantageous properties. Its exceptional resistance to corrosion makes it an ideal choice for components that are exposed to harsh weather conditions, like car exteriors and body panels. Stainless steel sheets are also renowned for their impressive strength-to-weight ratio, enabling the creation of lightweight yet sturdy automobile parts. Moreover, stainless steel exhibits remarkable heat resistance and can endure high temperatures, making it suitable for applications like exhaust systems. In summary, stainless steel sheets are extensively utilized in the automotive industry because of their durability, ability to resist corrosion, and versatility in various applications.

- Q: Are stainless steel sheets suitable for oil refineries?

- Yes, stainless steel sheets are suitable for oil refineries. Stainless steel is often chosen for its excellent resistance to corrosion, high temperature resistance, and durability. These properties make it highly suitable for the harsh conditions found in oil refineries, where the presence of corrosive chemicals, high temperatures, and constant exposure to moisture can be detrimental to other materials. Stainless steel sheets are commonly used in various applications within oil refineries, including storage tanks, pipelines, heat exchangers, and other equipment where corrosion resistance is crucial. Additionally, stainless steel sheets can be easily cleaned and maintained, which is important in maintaining the efficiency and functionality of equipment in oil refineries.

- Q: What are the different types of stainless steel sheet finishes for medical applications?

- Medical applications commonly utilize various types of stainless steel sheet finishes, each designed to possess specific qualities and characteristics necessary for such environments. A prevalent finish is the 2B finish, acquired through a cold-rolling process, which yields a smooth, reflective surface. This finish is frequently employed in medical instruments and equipment due to its ease of cleaning and high resistance to corrosion. Additionally, the No. 4 finish, also referred to as a satin finish, is widely used in medical cabinets and surfaces. This finish showcases a brushed appearance and offers a favorable combination of aesthetics and functionality. It boasts easy cleaning capabilities and reliable corrosion resistance. For more specialized applications, options like the No. 8 mirror finish are available. This finish exhibits a highly reflective surface and often finds application in surgical instruments and other high-end medical equipment. It not only presents a visually appealing surface but also demonstrates excellent corrosion resistance. Furthermore, alternative finishes, such as the bead blast finish, contribute to the medical equipment industry. This finish imparts a matte surface with a textured appearance, ideal for medical equipment requiring a non-reflective surface. Ultimately, the selection of a stainless steel sheet finish for medical applications depends on the specific requirements of the equipment or surface. Each finish possesses distinct advantages and characteristics, necessitating careful consideration to ensure optimal performance and longevity in a medical environment.

- Q: What are the benefits of using brushed stainless steel sheets in hospitality design?

- There are several benefits of using brushed stainless steel sheets in hospitality design. Firstly, brushed stainless steel sheets add a sleek and modern aesthetic to any space. The brushed finish creates a unique texture and visual appeal, making it a popular choice in contemporary design. This material can elevate the overall look and feel of a hospitality establishment, giving it a sophisticated and upscale ambiance. Secondly, brushed stainless steel sheets are highly durable and long-lasting. Stainless steel is known for its resistance to corrosion, scratches, and stains. In a high-traffic environment like a hotel or restaurant, where there is constant use and potential for spills, this durability is crucial. These sheets can withstand the wear and tear of daily use, ensuring they maintain their pristine appearance for years to come. Thirdly, brushed stainless steel sheets are easy to clean and maintain. They are non-porous, meaning they do not absorb liquids or odors. This makes them hygienic and suitable for use in hospitality settings where cleanliness is of utmost importance. A simple wipe down with a mild detergent is usually sufficient to remove any dirt or smudges, making it a practical choice for busy establishments. Additionally, brushed stainless steel sheets are available in a variety of finishes and colors, allowing for creative customization. This versatility enables designers to incorporate them into various design schemes, whether it be a minimalist, industrial, or even a more traditional look. The ability to choose from different textures and shades ensures that brushed stainless steel sheets can seamlessly integrate with the overall design concept of a hospitality space. Lastly, brushed stainless steel sheets are environmentally friendly. Stainless steel is fully recyclable, making it a sustainable choice in design. By opting for this material, hospitality establishments can contribute to reducing waste and minimizing their environmental footprint. In conclusion, the benefits of using brushed stainless steel sheets in hospitality design are numerous. From its aesthetic appeal and durability to its ease of maintenance and environmental sustainability, this material is an excellent choice for creating a stylish and functional space in the hospitality industry.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets typically ranges from 70 to 80 micro-ohm centimeters (µΩ·cm).

- Q: What are the advantages and disadvantages of net drawing stainless steel users?

- Brushed stainless steel refers to: stainless steel surface like filamentous texture, this is only a stainless steel processing technology. The surface is Matt, and carefully look at the above there is a trace of texture, but can not touch it.

- Q: Are stainless steel sheets safe for medical applications?

- Yes, stainless steel sheets are safe for medical applications. They are widely used in the medical industry due to their excellent corrosion resistance, biocompatibility, and durability. Stainless steel is easy to clean, sterilize, and maintain, making it suitable for surgical instruments, medical devices, and equipment used in healthcare settings.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The quality and consistency of stainless steel sheets are ensured by several common manufacturing standards. One widely recognized standard is the ASTM International standard, formerly known as the American Society for Testing and Materials. Specifically, the ASTM A240 standard specifies the chemical composition, mechanical properties, and other relevant characteristics of stainless steel sheets. Another important standard is the EN standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers dimensions, tolerances, surface finishes, and more. Different countries also have their own national standards. For example, in Japan, stainless steel sheets are classified under specifications such as JIS G4304 and JIS G4305, which are part of the Japanese Industrial Standards (JIS). These standards define the chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in manufacturing, and their properties are defined by the AISI. Manufacturers and suppliers must adhere to these standards to ensure that stainless steel sheets meet quality requirements and can be reliably used in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across industries.

- Q: Are stainless steel sheets resistant to sulfuric acid?

- Yes, stainless steel sheets are generally resistant to sulfuric acid.

Send your message to us

Stainless Steel Sheet/Plate 430 for Automobile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 8500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords