Stainless Steel Sheet CNBM ,Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

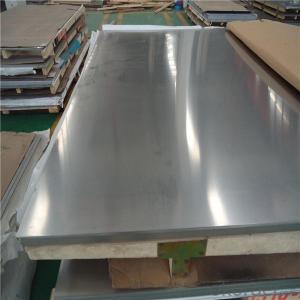

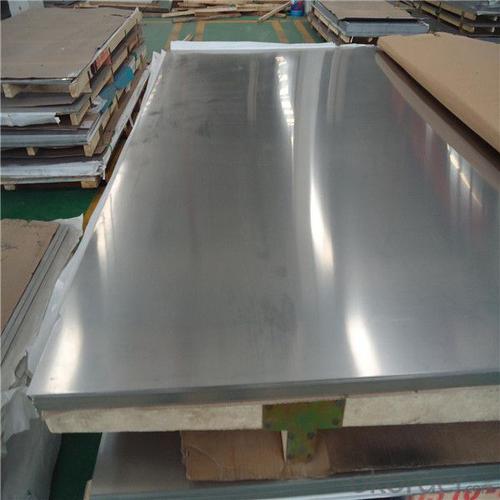

Stainless Steel Sheet

Features Stainless Steel Sheet:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information Stainless Steel Sheet:

1. Steel grade: 321

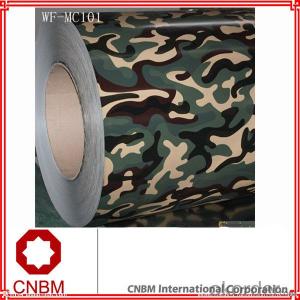

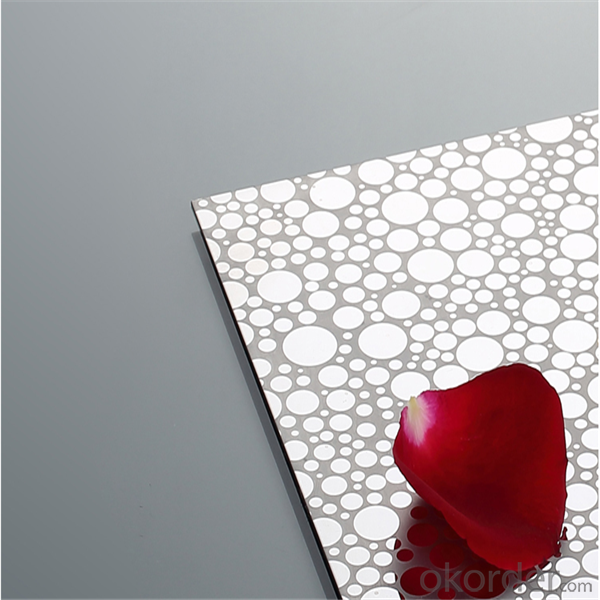

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

1. Specifications about stainless steel sheet

Commodity | stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 5 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

Stainless Steel Sheet

- Q: Are stainless steel sheets suitable for outdoor sculptures?

- Yes, stainless steel sheets are highly suitable for outdoor sculptures. Stainless steel is a durable and corrosion-resistant material, making it ideal for withstanding harsh outdoor conditions. It is resistant to rust, staining, and fading, making it a low-maintenance choice for outdoor sculptures. Additionally, stainless steel has a sleek and modern appearance, which can enhance the aesthetic appeal of outdoor artworks. Its strength and malleability also make it suitable for creating intricate and detailed sculptures. Therefore, stainless steel sheets are an excellent choice for outdoor sculptures, ensuring longevity and enhancing their visual impact.

- Q: What are the different types of etched finishes available for stainless steel sheets?

- There are several different types of etched finishes available for stainless steel sheets, each providing a unique and distinctive appearance. Some of the most common etched finishes include: 1. Brushed Finish: This is a popular etched finish that creates a uniform and linear texture on the surface of the stainless steel sheet. It is achieved by brushing the sheet with a fine abrasive material, resulting in a smooth and satin-like appearance. 2. Bead Blasted Finish: In this etched finish, small glass or ceramic beads are blasted onto the surface of the stainless steel sheet at high pressure. This process creates a non-directional and uniform texture, giving the sheet a matte and slightly rough appearance. 3. Mirror Finish: Also known as a No. 8 finish, this etched finish creates a highly reflective and mirror-like surface on the stainless steel sheet. It is achieved through a series of grinding, buffing, and polishing processes, resulting in a flawless and shiny appearance. 4. Satin Finish: This etched finish is similar to a brushed finish but has a finer and smoother texture. It is achieved by using a finer abrasive material during the brushing process, resulting in a soft and elegant appearance. 5. Patterned Finish: This etched finish involves creating various patterns or designs on the surface of the stainless steel sheet. It can be achieved through techniques such as laser etching, chemical etching, or embossing, allowing for a wide range of creative and customizable options. These different etched finishes offer a variety of aesthetic choices for stainless steel sheets, allowing them to be used in various architectural, decorative, and industrial applications. The choice of finish depends on the desired appearance, functionality, and intended use of the stainless steel sheet.

- Q: Can stainless steel sheets be used for architectural cladding?

- Yes, stainless steel sheets can be used for architectural cladding. Stainless steel is a popular choice for architectural cladding due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and modern look to buildings while also offering a long-lasting and low-maintenance solution for exterior cladding applications.

- Q: How do you prevent intergranular corrosion on stainless steel sheets?

- Intergranular corrosion, which causes structural damage and reduced strength, occurs along the grain boundaries of stainless steel. To prevent this corrosion on stainless steel sheets, several steps can be taken: 1. Material Selection: To prevent intergranular corrosion, it is crucial to select the appropriate grade of stainless steel. Grades like 304L or 316L, which have low carbon content, are less susceptible to this type of corrosion due to their reduced sensitivity to sensitization. 2. Heat Treatment: One can heat treat stainless steel sheets to eliminate carbide precipitation, a common cause of intergranular corrosion. This process, known as solution annealing or sensitization heat treatment, involves heating the material to a specific temperature range and rapidly cooling it. This treatment ensures the formation of a consistent and corrosion-resistant microstructure. 3. Passivation: Passivation is a chemical process that removes contaminants and forms a protective oxide layer on the surface of stainless steel sheets. This layer acts as a barrier against corrosion and prevents intergranular attack. Typically, nitric acid or citric acid solutions are used for passivation. 4. Welding Techniques: Proper welding techniques should be employed when welding stainless steel sheets to minimize the risk of intergranular corrosion. This includes using low heat input, preventing excessive heat build-up, and using filler materials with low carbon content to prevent sensitization. 5. Avoiding Contamination: It is essential to protect stainless steel sheets from contamination by other metals, particularly those with higher galvanic potentials. Contact with carbon steel, for instance, can lead to galvanic corrosion and promote intergranular attack. Therefore, it is important to store and fabricate stainless steel sheets separately from other metals. 6. Regular Cleaning and Maintenance: Regularly cleaning and maintaining stainless steel sheets is vital to prevent the accumulation of corrosive substances or contaminants on the surface. Non-abrasive cleaners and proper cleaning methods should be used to avoid scratching the stainless steel, as scratches can create sites for corrosion initiation. By implementing these preventive measures, one can significantly reduce intergranular corrosion, ensuring the durability and performance of stainless steel sheets.

- Q: How do you remove oil stains from stainless steel sheets?

- To remove oil stains from stainless steel sheets, you can start by wiping the surface with a clean, soft cloth dampened with warm water and mild dish soap. If the stain persists, apply a small amount of vinegar or rubbing alcohol onto the cloth and gently rub the affected area. Rinse with water and dry thoroughly to avoid water spots.

- Q: Can stainless steel sheets be used in outdoor environments?

- Yes, stainless steel sheets can be used in outdoor environments. Stainless steel is highly resistant to corrosion, making it suitable for outdoor applications. It can withstand exposure to harsh weather conditions, such as rain, sunlight, and temperature fluctuations, without deteriorating. Additionally, stainless steel is also resistant to rust, staining, and oxidation, further enhancing its suitability for outdoor use. This makes stainless steel sheets a popular choice for various outdoor applications, including construction, architecture, signage, and outdoor furniture.

- Q: How do you prevent fingerprints on stainless steel sheets?

- To prevent fingerprints on stainless steel sheets, there are several steps you can take: 1. Clean the surface: Before taking any preventive measures, make sure to thoroughly clean the stainless steel sheets using a mild detergent or stainless steel cleaner. This will remove any existing fingerprints or smudges. 2. Use gloves: When handling stainless steel sheets, wear gloves to prevent transferring natural oils from your hands onto the surface. Opt for cotton or nitrile gloves, as they provide a good grip and won't leave behind residue. 3. Avoid touching directly: Try to minimize touching the stainless steel surface as much as possible. This can be achieved by using specialized tools or wearing gloves when handling and installing the sheets. 4. Apply a protective coating: There are various protective coatings available in the market specifically designed for stainless steel. These coatings create a barrier that repels fingerprints and makes cleaning easier. Follow the manufacturer's instructions for proper application. 5. Use microfiber cloth: When you need to clean the stainless steel sheets, use a soft microfiber cloth. Microfiber is gentle on the surface and helps prevent streaks and fingerprints. Avoid using abrasive materials or rough scrubbers that can damage the stainless steel finish. 6. Regular cleaning routine: Establish a regular cleaning routine to remove any fingerprints or smudges that may appear over time. Dilute a mild detergent in warm water and use a soft cloth or sponge to wipe down the stainless steel sheets. Rinse with clean water and dry thoroughly. By following these preventive measures and cleaning techniques, you can significantly reduce the appearance of fingerprints on stainless steel sheets and keep them looking clean and pristine.

- Q: How do you prevent scratches or dents on stainless steel sheets?

- To prevent scratches or dents on stainless steel sheets, there are a few measures you can take: 1. Handle with care: When handling stainless steel sheets, be cautious to avoid dropping or dragging them against rough surfaces. Use gloves or protective gear to minimize the risk of scratches caused by sharp objects or tools. 2. Clean with soft materials: To prevent scratches during cleaning, use soft cloths or non-abrasive sponges. Avoid using steel wool or harsh cleaning agents that can damage the surface. Additionally, always wipe in the direction of the grain to maintain the stainless steel's appearance. 3. Use protective films or sheets: Applying a protective film or sheet to the stainless steel surface can provide an extra barrier against scratches or dents. These films are typically adhesive and can be easily removed once the stainless steel sheets are installed. 4. Store properly: Store stainless steel sheets in a clean and dry environment to prevent scratches or dents caused by contact with other objects. Avoid stacking sheets directly on top of each other without any protective barrier in between. 5. Invest in edge protectors: Stainless steel sheets are often susceptible to dents or scratches on their edges. Using edge protectors or corner guards can help prevent damage during handling, transportation, or storage. By following these preventive measures, you can significantly reduce the chances of scratches or dents on stainless steel sheets, ensuring their longevity and maintaining their pristine appearance.

- Q: Can stainless steel sheets be used for signage?

- Stainless steel sheets are indeed capable of serving as signage. This material possesses durability and longevity, being highly resistant to corrosion, thereby rendering it suitable for both indoor and outdoor applications. Its sleek and contemporary appearance contributes to its popularity across various signage types, encompassing company logos, directional signs, nameplates, and even expansive outdoor billboards. The flexibility of stainless steel sheets allows for easy customization through cutting, engraving, or laser-etching, thereby offering a vast array of creative possibilities. Furthermore, the choice of stainless steel signage often stems from its ability to withstand adverse weather conditions, UV rays, and acts of vandalism, thereby preserving the integrity and legibility of the signage for numerous years.

- Q: Are stainless steel sheets available in different colors?

- No, stainless steel sheets are typically only available in their natural silver color. Stainless steel is a type of steel alloy that contains chromium, which gives it its characteristic silver appearance. While it is possible to treat stainless steel sheets with various coatings or finishes to achieve a different color, such as black or gold, these are not typically available as standard options. However, there are alternatives like powder coating or painting stainless steel sheets to achieve different colors, but these processes may affect the material's corrosion resistance and durability.

Send your message to us

Stainless Steel Sheet CNBM ,Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords