All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

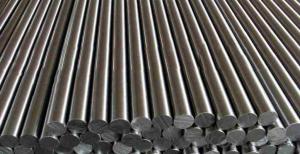

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does hot-rolled steel perform in applications with strict seismic codes?

Hot-rolled steel performs well in applications with strict seismic codes due to its inherent strength and ductility. The material's ability to absorb and redistribute energy during seismic events makes it a reliable choice for constructing structures that need to withstand earthquakes. The flexibility of hot-rolled steel allows it to deform without fracturing, ensuring the safety and stability of buildings in high-risk seismic zones.

How is hot-rolled steel tested for quality and integrity?

Hot-rolled steel is tested for quality and integrity through various methods. One common method is visual inspection where the steel surface is examined for any defects, such as cracks, surface irregularities, or scale. Additionally, mechanical testing is conducted to assess the steel's strength, ductility, and toughness. This can include tensile and hardness tests. Ultrasonic testing is also utilized to detect internal flaws by sending sound waves through the steel and analyzing the reflected waves. Magnetic particle testing is another technique that uses magnetic fields and iron particles to identify surface or near-surface defects. Overall, a combination of these methods ensures that hot-rolled steel meets the required quality and integrity standards.

What is the role of hot rolled steel in the production of structural steel sections?

The role of hot rolled steel in the production of structural steel sections is significant as it is the initial stage in the manufacturing process. Hot rolled steel is produced by heating the steel at high temperatures, which makes it more malleable and easier to shape. This process allows for the creation of various structural steel sections, such as beams, columns, and channels. Hot rolled steel sections are known for their strength and durability, making them suitable for construction projects that require robust and reliable structural components.

How does hot rolled steel perform in extreme weather conditions?

Hot rolled steel performs well in extreme weather conditions due to its high tensile strength and durability. It retains its structural integrity even in extremely hot or cold temperatures, making it suitable for various applications such as construction, transportation, and infrastructure.

Wholesale Hot Rolled Steel from supplier in Grenada

We are a Hot Rolled Steel supplier serving the Grenada, mainly engaged in the sale, quotation, and technical support services of various Hot Rolled Steel products in the Grenada region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Hot Rolled Steel procurement services in the Grenada. Not only do we have a wide range of Hot Rolled Steel products, but after years of market development in the Grenada, we can also provide valuable experience for your projects.