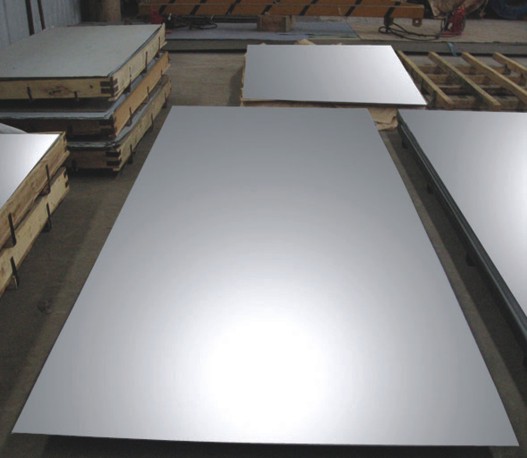

Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm: 25 Tons/20FCL.

Grade of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm: 201, 306, 316 Etc.

Delivery Time of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm: 20 days Per Container.

Application of Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: How do you prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, it is essential to avoid exposure to corrosive substances, such as salt, bleach, and strong acids. Regular cleaning with mild soap and water, followed by thorough drying, can help maintain the stainless steel's appearance. Additionally, applying a protective coating or using specialized cleaning products made for stainless steel can provide an extra layer of defense against discoloration.

- Q: What are the different types of stainless steel sheet surface textures for decorative purposes?

- There are several types of stainless steel sheet surface textures that are commonly used for decorative purposes. These textures can enhance the overall aesthetic appeal of the stainless steel sheet and make it suitable for various applications. Some of the different types of stainless steel sheet surface textures include: 1. Brushed Finish: This texture is achieved by rubbing the stainless steel sheet surface with a fine abrasive material, resulting in a uniform satin-like appearance. Brushed finish is popular for its smooth and subtle texture, making it suitable for various decorative applications. 2. Mirror Finish: Also known as a highly reflective finish, the mirror finish is achieved by polishing the stainless steel sheet surface to a high gloss. This texture creates a mirror-like reflection and is often used in decorative applications where a sleek and modern appearance is desired. 3. Bead Blast Finish: This texture is created by blasting the stainless steel sheet surface with small glass beads, resulting in a matte and textured appearance. Bead blast finish is commonly used in decorative applications where a non-reflective and textured surface is desired. 4. Embossed Finish: This texture involves creating patterns or designs on the stainless steel sheet surface by stamping or pressing it with a patterned roller or plate. Embossed finishes can vary in pattern and depth, adding a visually appealing and tactile element to the stainless steel sheet. 5. Etched Finish: This texture is achieved by chemically etching the stainless steel sheet surface with an acid or other corrosive substances. Etched finishes can create various designs, patterns, or even images on the surface, making it ideal for decorative applications where intricate detailing is required. 6. Hairline Finish: This texture is created by mechanically polishing the stainless steel sheet surface with fine abrasive belts or brushes, resulting in a narrow and uniform textured pattern. Hairline finishes are commonly used in decorative applications where a subtle and elegant appearance is desired. These are just a few examples of the different types of stainless steel sheet surface textures available for decorative purposes. Each texture offers a unique visual and tactile quality, allowing for a wide range of design options when using stainless steel sheets for decorative applications.

- Q: What is the standard size of a stainless steel sheet?

- The size of a stainless steel sheet can vary depending on the manufacturer and the specific application. Different standard sizes are commonly available, such as 4 feet by 8 feet (1220mm by 2440mm) or 4 feet by 10 feet (1220mm by 3050mm). These dimensions are widely used in industries like construction, manufacturing, and fabrication. Moreover, stainless steel sheets are also available in various thicknesses, ranging from 0.4mm to 6mm or more, depending on the intended use and requirements. It's worth noting that manufacturers can provide custom sizes and dimensions for specific projects or applications that require non-standard sizes.

- Q: What are the different types of stainless steel sheet coatings available?

- There are several different types of stainless steel sheet coatings available, each offering unique properties and benefits. Some of the most common types include: 1. Galvanized Coatings: These coatings are made by applying a layer of zinc to the surface of the stainless steel sheet. This helps to protect the steel from corrosion and rusting. Galvanized coatings are commonly used in outdoor applications or in environments where the steel is exposed to moisture or chemicals. 2. Powder Coatings: Powder coatings are a popular choice for stainless steel sheets as they provide excellent durability and resistance to corrosion. This type of coating is applied as a dry powder and then heated to form a hard protective layer. Powder coatings come in a variety of colors and finishes, allowing for customization and aesthetic appeal. 3. Electroplating: Electroplating involves the deposition of a thin layer of another metal onto the stainless steel sheet. Common metals used for electroplating include chrome, nickel, and zinc. This coating not only enhances the appearance of the steel but also improves its resistance to corrosion and wear. 4. PVD Coatings: Physical Vapor Deposition (PVD) coatings involve the deposition of a thin film onto the stainless steel sheet using a vacuum process. These coatings can provide various properties such as improved hardness, scratch resistance, and color options. PVD coatings are commonly used in architectural applications or for decorative purposes. 5. Organic Coatings: Organic coatings, such as paints or lacquers, can also be applied to stainless steel sheets. These coatings provide an additional layer of protection against corrosion, as well as offering aesthetic options. Organic coatings are often used in applications where color matching or branding is important. Each type of stainless steel sheet coating has its advantages and is suitable for specific applications. The choice of coating will depend on factors such as the intended use, desired appearance, and environmental conditions in which the stainless steel will be exposed. It is important to carefully consider these factors and consult with experts to choose the most suitable coating for your specific needs.

- Q: What are the cost considerations when purchasing stainless steel sheets?

- There are several cost considerations to bear in mind when buying stainless steel sheets. The cost is greatly influenced by the grade of stainless steel. Stainless steel comes in different grades, each with its own properties and levels of corrosion resistance. Higher grades like 316 or 304 are generally more expensive due to their superior corrosion resistance and durability. The size and thickness of the sheets also impact the cost. Thicker sheets are generally more expensive than thinner ones, and larger sheets are priced higher than smaller ones. It's important to accurately determine the required size and thickness to avoid unnecessary expenses. The surface finish is another factor that can affect the cost. Stainless steel sheets are available in various finishes, including brushed, mirror, or matte. Finishes that require additional processing or polishing usually add to the overall cost. Moreover, the quantity of sheets needed can have an impact on pricing. Bulk purchases often come with discounts or lower per-unit costs compared to buying small quantities. Transportation and delivery costs should also be taken into account. Stainless steel sheets are heavy and can be costly to transport, especially if shipping over long distances. These costs should be factored in to ensure that the overall purchase remains within budget. Finally, it is crucial to consider the reputation and reliability of the supplier. While lower-priced options may be tempting, it's important to ensure that the supplier offers high-quality stainless steel sheets that meet the required specifications. Purchasing from a reputable supplier may come at a slightly higher cost, but it guarantees the quality and reliability of the product. In conclusion, when purchasing stainless steel sheets, it's vital to consider the grade, size, thickness, surface finish, quantity, transportation costs, and the reputation of the supplier. By carefully considering these factors, one can make an informed decision that balances cost-effectiveness with the desired quality and specifications.

- Q: Are stainless steel sheets suitable for water tanks?

- Yes, stainless steel sheets are suitable for water tanks. Stainless steel is highly resistant to corrosion and rust, making it an ideal material for water storage. It is durable, long-lasting, and can withstand high water pressures. Additionally, stainless steel is hygienic, easy to clean, and does not contaminate the water.

- Q: Can stainless steel sheets be used for decorative ceiling tiles?

- Yes, stainless steel sheets can indeed be used for decorative ceiling tiles. Stainless steel is a versatile material that offers a modern and sleek appearance, making it a popular choice for decorative purposes. Its durability, resistance to corrosion, and ability to withstand high temperatures also make it suitable for ceiling applications. Additionally, stainless steel sheets can be easily customized with various finishes, patterns, and designs to create unique and visually appealing ceiling tiles.

- Q: Are stainless steel sheets resistant to nitric acid?

- Stainless steel sheets are typically known for their resistance to nitric acid. Nitric acid, an extremely powerful oxidizing agent, has the ability to corrode and dissolve numerous metals. However, stainless steel contains a significant amount of chromium, which creates a protective oxide layer on the material's surface. This oxide layer acts as a barrier, effectively preventing direct contact between the nitric acid and stainless steel, thereby providing corrosion resistance. It is crucial to acknowledge that the level of resistance may differ depending on various factors such as the grade and composition of the stainless steel, as well as the nitric acid's concentration and temperature.

- Q: How do you calculate the bending radius for stainless steel sheets?

- To calculate the bending radius for stainless steel sheets, you need to consider the material's thickness, tensile strength, and the desired level of bendability. The bending radius can be determined using formulas or tables specific to stainless steel, taking into account these factors to ensure the sheet does not crack or deform during bending.

- Q: Can stainless steel sheets be used for aerospace fasteners?

- Aerospace fasteners can indeed utilize stainless steel sheets. The reason for stainless steel's popularity in aerospace applications lies in its exceptional resistance to corrosion, impressive strength, and long-lasting nature. This material can endure both extreme temperatures and challenging environments, rendering it suitable for aircraft components that face demanding conditions. By manipulating stainless steel sheets into various shapes and sizes, they can function as fasteners like screws, bolts, and rivets, providing a dependable and secure connection within aerospace structures. Furthermore, stainless steel's lack of magnetic properties proves advantageous in specific aerospace scenarios where reducing magnetic interference becomes crucial. All in all, stainless steel sheets represent a trustworthy and extensively employed choice for aerospace fasteners.

Send your message to us

Stainless Steel Sheet 4K Surface Treatment 2mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords