Stainless Steel Plate 443 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

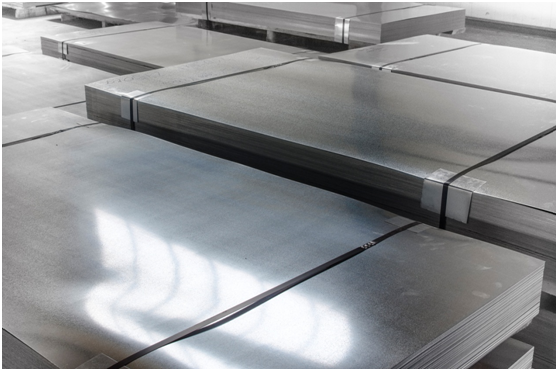

Stainless Steel Plate 443 with Surface Treatment

Description of Stainless Steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Material |

201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L

|

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

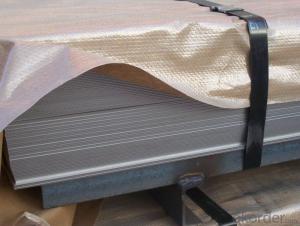

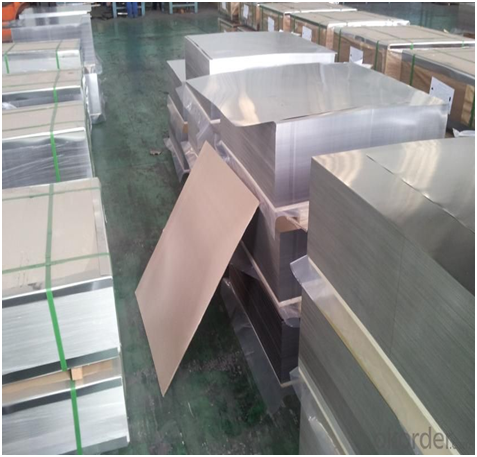

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Main Features of stainless steel sheet :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

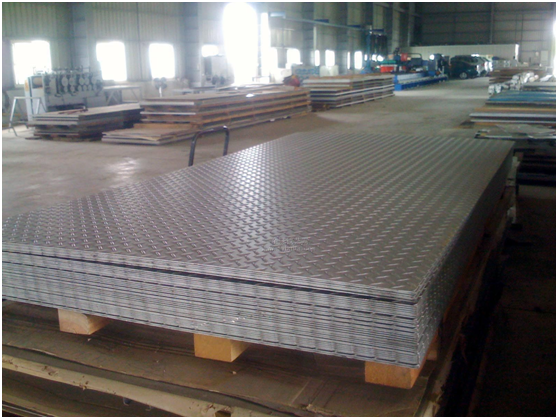

Cold Rolled and Hot Rolled:

Packaging & Shipping

Our Services

Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured.

Company Information

CNBM(China National Building Material Company)International Corporation is a state owned Enterprise.

We are listed in the fortune global 500 companies, and we are the second largest building material company in the world.

We are specialized in producing stainless steel coil, stainless steel (plate/sheet), and duplex stainless steel for a prelonged period. We are currently doing grade of steel of 201/202,304/304L, 310S/309S/316L/316Ti/321,410/420/430/444/443/409L, and 904L.

FAQ

1. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

2. How long do we usually reply your request?

We always reply our customer within 24 hours.

3. What material are we supplying now?

We are specialized in producing Stainless Steel Coil, Stainless steel(plate/sheet), and duplex stainless steel for 2 decades. We are currently supplying 201/202, 304/304l, 310S/309S/316l/316Ti/321, 410/420/430/444/443/409l, and 904l.

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- It has excellent corrosion resistance, acid, alkali and salt corrosion, which can meet the special requirements of oil well, not because of the erosion of the gap becomes larger; one welding multilayer structure, can make the filter hole stability, anti deformation ability.

- Q: What are the different surface finishes available for stainless steel sheets?

- Stainless steel sheets come in a variety of surface finishes, each with its own unique characteristics and aesthetics. Let's explore some of the options available: 1. The No.1 Finish is the most commonly used finish for stainless steel sheets. It has a rough and dull appearance with visible grain lines. This finish is achieved through hot rolling and is suitable for applications where a rough finish is acceptable. 2. For a smooth and slightly dull surface, the No.2B Finish is ideal. It is obtained by cold rolling and annealing the stainless steel. This finish is commonly used for kitchen appliances, architectural accents, and decorative purposes. 3. Similar to the No.2B Finish, the No.2D Finish also involves cold rolling and annealing. However, it has a smoother and shinier appearance, making it suitable for applications that require a more polished look. 4. The No.3 Finish, also known as a brushed finish, is achieved by polishing the stainless steel with abrasive belts or brushes. It creates a unidirectional satin-like appearance, often used for decorative purposes in architecture and interior design. 5. If you desire a more refined and smoother appearance, the No.4 Finish is the way to go. This finish is obtained by polishing the stainless steel with finer abrasive belts or brushes than the No.3 Finish. It is commonly used for decorative purposes, such as elevator panels, kitchen equipment, and automotive trim. 6. For a highly reflective surface, the No.8 Finish, also known as a mirror finish, is perfect. This finish is achieved by continuously polishing the stainless steel with finer abrasive materials until a glossy, mirror-like appearance is obtained. It is ideal for architectural and decorative applications. 7. The Hairline Finish is achieved by mechanically polishing the stainless steel surface with a fine abrasive material. It creates a subtle, linear pattern with a matte appearance, commonly used for architectural accents, appliances, and decorative items. These are just some of the most common surface finishes available for stainless steel sheets. The choice of finish will depend on the desired aesthetics, functionality, and application requirements.

- Q: What are the different types of stainless steel sheet patterns available?

- There exists a variety of stainless steel sheet patterns, each possessing its own distinct design and characteristics. Some commonly encountered patterns include: 1. Smooth or plain: This pattern serves as the most elementary and widespread option, showcasing a sleek and uncomplicated surface without any discernible texture or design. 2. Satin or brushed: By subjecting the stainless steel sheet to the gentle abrasion of a fine grit abrasive, this pattern is achieved, resulting in a uniform and directional grain. It imparts a subtle and sophisticated appearance. 3. Quilted or diamond: With a raised diamond-shaped design on its surface, this pattern enhances traction and slip resistance. It finds frequent application in flooring, stairs, and industrial settings. 4. Linen: Resembling the texture of linen fabric, this pattern is achieved by etching a series of parallel lines onto the stainless steel sheet. It adds a distinctive visual appeal and is suitable for various uses, including interior design and architectural projects. 5. Perforated: Comprising a series of small holes or perforations punched into the stainless steel sheet, this pattern creates a visually captivating and functional design. It is commonly employed in situations requiring ventilation or filtration. 6. Tread or checker: Displaying a raised checkerboard design on the surface of the stainless steel sheet, this pattern offers a non-slip surface. It is often utilized in flooring, stairs, and transportation equipment. These examples merely scratch the surface of the diverse array of stainless steel sheet patterns available. Each pattern offers a unique combination of aesthetics and functionality, enabling versatile use across a wide range of applications.

- Q: What are the features of stainless steel plates?

- Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium. It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

- Q: Can stainless steel sheets be used in the aerospace industry?

- Yes, stainless steel sheets can be used in the aerospace industry. Stainless steel possesses excellent strength, corrosion resistance, and high-temperature stability, making it suitable for various aerospace applications such as aircraft frames, engine components, and structural parts.

- Q: Can stainless steel sheets be used for electrical or electronic applications?

- Yes, stainless steel sheets can be used for electrical or electronic applications. Stainless steel has excellent electrical conductivity and is resistant to corrosion, making it an ideal material for various electrical components. It is commonly used in electrical enclosures, switchgear, control panels, and other electrical equipment. Additionally, stainless steel sheets can be fabricated into different shapes and sizes, making them suitable for various electronic applications such as printed circuit boards (PCBs), connectors, and terminals. The durability and high temperature resistance of stainless steel also make it a preferred choice for electrical and electronic applications in harsh environments.

- Q: Are stainless steel sheets resistant to radiation?

- Yes, stainless steel sheets have excellent resistance to radiation. The high levels of chromium present in stainless steel make it highly resistant to corrosion and oxidation caused by radiation exposure. This property makes stainless steel sheets a suitable choice for various applications in nuclear power plants, medical facilities, and other industries that involve exposure to radiation.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Yes, stainless steel sheets can be used for medical instrument trays. Stainless steel is a commonly used material in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. Medical instrument trays are used to store and organize various medical instruments during procedures. Stainless steel sheets are ideal for this purpose as they are non-reactive and can withstand frequent sterilization processes such as autoclaving. Additionally, stainless steel has a smooth surface that is resistant to scratches and dents, ensuring the trays remain hygienic and easy to clean. Overall, stainless steel sheets are a reliable and suitable material choice for medical instrument trays.

- Q: What does 8K stainless steel mean?

- The literal definition of 8K: the composition of the alloy corrosion resistance of stainless steel white just depends on its (Cr, Ni, Ti, Si, Mn) and internal organizational structure, which play a decisive role is chromium, it can form a passivation film on the surface of the steel, the metal isolation does not produce oxidation and enhance the ability of corrosion resistance of steel plate. In 8K, the "8" refers to the proportion of ingredients containing alloy (304 stainless steel mainly refers to the content of Ni element), "K" refers to after polishing after the reflectance grade (grade K grade mirror). 8K mirror, that is, chrome nickel alloy steel reflects the mirror level.

- Q: Are stainless steel sheets suitable for high-temperature environments?

- Stainless steel sheets are generally considered suitable for high-temperature environments. The reason for this is that stainless steel possesses exceptional heat resistance and retains its structural integrity even at elevated temperatures. The maximum temperature resistance of stainless steel depends on the specific grade used. Austenitic stainless steel varieties, such as 304 and 316, can endure temperatures as high as 870°C (1600°F). In contrast, ferritic stainless steel, like 430, has a slightly lower maximum temperature limit of approximately 760°C (1400°F). Moreover, the corrosion resistance, durability, and ease of maintenance of stainless steel sheets make them a popular choice for high-temperature applications.

Send your message to us

Stainless Steel Plate 443 with Surface Treatment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords