Stainless Steel Coil Cold Rolled 201 Half Cu 0.8 Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Stainless Steel Coil Cold Rolled 201 Descriptions

Stainless Steel 201 is a new kind of Austenite stainless steel by used Mn, N replace Ni. The steel has good corrosion resistance and hot / cold processing performance, instead of 304 stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2. Main Features of the Stainless Steel Coil Cold Rolled 201

Product name: Stainless Steel Coil Cold Rolled 201

Thickness: 0.2mm to 1.5mm

Technical: Cold Rolled

Width: 10mm to 1240mm

Type: 200 Series

Length: As customer's requested

Standard: JIS, SUS, AISI, ASTM

Grade: 201-J1, 201-J4, AISI201, AISI202…

Finish: BA, 2B, 8K, NO.3, NO.4, HL…

MOQ: 25 Metric Tons

Hardness: Low Hard(190 HV Max); Half Hard(240-280HV); Full Hard(42-60 HRC)

Ship Term: FOB any port, China or CFR Destination port

Delivery Time: 15 to 20 day after the receive the deposit or 100%LC

Payment Terms: TT 30% for deposit, Balance against the copy of B/L, or 100%LC

Packaging: By wooden pallet, wooden case or according to customer's request

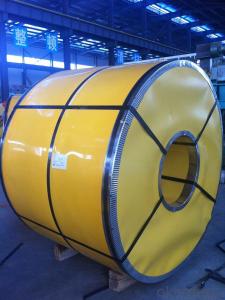

3. Stainless Steel Coil Cold Rolled 201 Images

4. Stainless Steel Coil Cold Rolled 201 Specifications

Mechanical Property Contrast | YS (Mpa) | TS (Mpa) | EL(%) | HV | REMARK |

Stainless Steel 201 | 426 | 880 | 52 | 224 | 1.0t |

Stainless Steel 304 | 285 | 710 | 58 | 165 | 1.0t |

Stainless Steel 200 Series Chemicals Contrast (wt. %) | ||||||||

Chemicals | C | Si | Mn | Cr | Ni | N | Other | |

205 | 0.12-0.25 | ≤0.75 | 14.0-15.0 | 16.5-18.0 | 1.0-1.75 | 0.32-0.4 | ||

JIS, | 201 | ≤0.15 | ≤1.0 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - |

201L | ≤0.03 | ≤0.75 | 5.5-7.5 | 16.0-18.0 | 3.5-5.5 | ≤0.25 | - | |

202 | ≤0.15 | ≤1.0 | 7.5-10.0 | 17.0-19.0 | 4.0-6.0 | ≤0.25 | - | |

201LN | ≤0.03 | ≤0.75 | 6.4-7.5 | 16.0-17.5 | 4.0-5.5 | 0.1-0.25 | Cu≤1.0 | |

India | 201-J1 | ≤0.08 | ≤0.75 | 7.0-8.0 | 15.0-17.0 | 4.0-5.0 | ≤0.1 | Cu≤1.5 |

201-J3 | ≤0.08 | ≤0.75 | 9.0-10.5 | 14.0-16.0 | 2.0-3.0 | ≤0.15 | Cu≤2.0 | |

201-J4 | ≤0.10 | ≤0.75 | 8.5-10.0 | 15.0-16.0 | ≤1.2 | ≤0.2 | Cu≤2.0 | |

America | 204 | ≤0.03 | ≤1.0 | 7.0-9.0 | 15.0-17.0 | 1.5-3.0 | 0.15-0.3 | (Cu) |

H400 | ≤0.10 | ≤1.0 | 6.0-9.0 | 17.0-19.5 | ≤3.5 | ≤0.3 | - | |

Japan | YUS130S | 0.09 | 0.5 | 11.0 | 18.0 | 6.5 | 0.35 | - |

NTK S-4 | 0.17 | 0.43 | 14.7 | 17.7 | 1.3 | 0.35 | - | |

NM15M | 0.08 | 0.8 | 14.5 | 17.0 | 4.3 | 0.33 | - | |

Europe America | 219 | ≤0.04 | ≤0.75 | 8.0-10.0 | 19.0-21.5 | 5.5-7.5 | 0.15-0.4 | - |

Cromanite | ≤0.08 | ≤1.0 | 9.5-11.0 | 18.0-20.0 | ≤1.0 | 0.4-0.6 | - | |

201 Surface | Characteristic and Application of Stainless Steel Coil Cold Rolled 201 |

2B | The surface brightness and flatness of 2B is better than 2D then through a special surface treatment to improve its mechanical properties,2B could nearly Satisfy comprehensive uses |

No.4 | Polished with abrasive belt of grit#150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and electrical appliances kitchen utensils and food processing. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness like mirror kitchen apparatus, etc. |

8K | The product have excellent brightness and prefer bright can be the mirror. |

5. FAQ of Stainless Steel Coil Cold Rolled 201

Q: Can you provide mill test certificate?

A: Yes! Mill test certificate for both hot rolled raw material coils and cold rolled coils are available.

Q: How to get a sample?

A: Free samples are available for your checking and testing. And to get free samples, please send us your detailed receiving address (including post code) and your DHL/FEDEX/UPS account for collecting samples, courier cost will be paid in your side.

Q: How about your company?

A world class manufacturer & supplier of castings forging in stainless steel, is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 90000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service are available, all according to customer’s requirements.

Q: How to guarantee the quality of the products?

A: We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

Q: How is the packaging and delivery?

A: Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden box), or as your requirement and the delivery term is based on the project.

- Q: Can stainless steel strips be coated or painted?

- Yes, stainless steel strips can be coated or painted.

- Q: Can stainless steel strips be used in construction applications?

- Certainly, construction applications can indeed utilize stainless steel strips. Stainless steel, known for its outstanding durability, strength, and resistance to corrosion, proves to be an incredibly versatile material. These remarkable qualities render it suitable for an extensive array of construction applications, including structural components, roofing, cladding, flooring, and decorative elements. In fact, stainless steel strips find their place in the construction of buildings, bridges, pipelines, and various other infrastructure projects. They are particularly favored in areas demanding exceptional strength and resilience against harsh environmental conditions. Moreover, stainless steel strips can be easily tailored and customized to fulfill specific construction requirements, making them a highly sought-after choice within the industry.

- Q: How do you prevent corrosion fatigue of stainless steel strips?

- To prevent corrosion fatigue of stainless steel strips, there are several measures that can be taken: 1. Proper material selection: Choose a stainless steel grade that is resistant to corrosion and fatigue. Grades such as 316 and 304L are commonly used for their excellent corrosion resistance properties. 2. Surface treatment: Apply a protective coating or passivation treatment to the stainless steel strips. This will enhance the corrosion resistance and prevent the initiation of fatigue cracks. 3. Regular cleaning and maintenance: Keep the stainless steel strips clean and free from contaminants that can accelerate corrosion. Regularly inspect the strips for any signs of corrosion or fatigue and address them promptly. 4. Avoid harsh environments: Limit exposure of the stainless steel strips to corrosive environments such as saltwater, acidic solutions, or high humidity conditions. If exposure is necessary, consider implementing additional protective measures like applying a barrier coating or using cathodic protection. 5. Proper handling and storage: Handle the stainless steel strips with care to prevent any damage that could lead to corrosion or fatigue cracks. Store them in a dry and controlled environment to avoid exposure to moisture or other corrosive agents. 6. Design considerations: Ensure that the design of the stainless steel strips takes into account factors such as stress concentration, surface finish, and proper installation techniques. These considerations can help minimize the risk of fatigue and corrosion. 7. Regular inspections and testing: Implement a regular inspection and testing program to detect any early signs of corrosion fatigue. This can include visual inspections, non-destructive testing methods, and monitoring of environmental conditions. By implementing these preventive measures, the risk of corrosion fatigue in stainless steel strips can be significantly reduced, ensuring their long-term durability and performance.

- Q: Are stainless steel strips suitable for chemical pipes?

- Yes, stainless steel strips are suitable for chemical pipes. Stainless steel is highly resistant to corrosion and can withstand the corrosive effects of various chemicals, making it a suitable material for constructing chemical pipes.

- Q: What are the typical hardness values of stainless steel strips?

- The typical hardness values of stainless steel strips can vary depending on the specific grade and type of stainless steel being used. However, stainless steel strips generally have a hardness range between 150 and 250 on the Vickers hardness scale (HV). Some grades of stainless steel may have higher hardness values, reaching up to 300 HV or more, while others may have lower hardness values, closer to the lower end of the range. It is important to note that the hardness of stainless steel strips can also be influenced by factors such as the heat treatment process and the thickness of the strip.

- Q: Can 111 stainless steel strips be coated or plated for added protection?

- 111 stainless steel strips have the capability to be coated or plated for extra protection. By adding a protective layer to the strips, their resistance to corrosion, wear, and other types of damage can be improved. The choice of coating or plating material will be determined by the desired level of protection and the intended application of the strips. When it comes to stainless steel, common coating options consist of epoxy, acrylic, and powder coatings, while plating options may include nickel, chrome, or zinc. To ensure the best coating or plating technique is selected, it is essential to thoroughly consider the intended use and environment of the strips.

- Q: Can 111 stainless steel strips be used in the automotive industry?

- Indeed, the automotive industry can make use of 111 stainless steel strips. Due to its exceptional resistance to corrosion, great strength, and durability, stainless steel finds widespread application in the automotive sector. In particular, the grade 111 stainless steel is renowned for its favorable formability and weldability, rendering it suitable for a variety of automotive uses. These strips can find utility in the construction of car bodies, exhaust systems, fuel tanks, and other components that necessitate resistance to corrosion and impressive mechanical properties. Moreover, the integration of stainless steel strips within the automotive industry aids in enhancing safety measures, improving fuel efficiency, and reducing the overall weight of vehicles.

- Q: Can 111 stainless steel strips be polished to a mirror-like finish?

- Yes, 111 stainless steel strips can be polished to a mirror-like finish. The ability to achieve a mirror-like finish depends on the quality of the stainless steel strips and the polishing method used. Stainless steel has a natural ability to be polished to a high shine due to its smooth surface and corrosion resistance. However, achieving a mirror-like finish requires a thorough polishing process involving multiple stages of abrasive materials and polishing compounds. With the right equipment and technique, it is possible to polish 111 stainless steel strips to a mirror-like finish, resulting in a highly reflective and visually appealing surface.

- Q: How do you determine the grade of a stainless steel strip?

- The grade of a stainless steel strip is determined by its chemical composition, which includes the percentages of various elements such as chromium, nickel, and carbon. Additionally, the properties of the stainless steel strip, such as its corrosion resistance, strength, and heat resistance, are considered when determining its grade. Various testing methods, including spectroscopy and mechanical tests, are used to analyze these factors and assign the appropriate grade to the stainless steel strip.

- Q: How do stainless steel strips resist scaling?

- Stainless steel strips resist scaling primarily due to the presence of chromium in their composition. The chromium content in stainless steel forms a passive oxide layer on the surface, known as chromium oxide. This thin layer acts as a protective barrier against oxidation, preventing the metal from further reacting with oxygen in the environment and thus resisting scaling. Additionally, the presence of other alloying elements such as nickel and molybdenum further enhances the corrosion resistance and scaling resistance properties of stainless steel strips. The combination of these elements creates a stable and durable oxide layer, making stainless steel highly resistant to scaling even at high temperatures.

Send your message to us

Stainless Steel Coil Cold Rolled 201 Half Cu 0.8 Prime Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords