Square Steel Pipe from Okorder in China with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Square Steel Pipe Description:

The square Steel pipes are used in structural projects, shelves, racks, trailers and in ornamental purpose. The framework made by square steel tubes, is used for providing support to the roof. This framework is also used as roof top ventilation baffles. With compare to round steel pipes, square steel pipes are little more efficient. The reason is that the square column is more efficient than the solid circular column.

2. Main Features of the Square Steel Pipe:

·Prompt delivery

·Time-saving

·High quality

·Competitive price

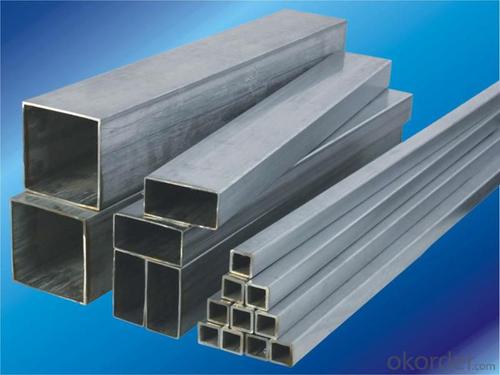

3. Square Steel Pipe Images:

4、Square Steel Pipe Specification:

| Standard | JIS,GB,DIN,ASTM JIS G3466, GB/T 3094-2000, DIN EN 10216-1-2004, ASTM A513-2007 |

| Grade | Cr-Mo alloy, 16Mn, A53-A369, Q195-Q345 30CrMo, 16Mn, A106(B,C), Q235, Q345, Q195, Q215 |

| Thickness | 0.5 - 30 mm |

| Outer Diameter | 10x10---600x600 |

| Technique | Cold Drawn |

| Application | Structure Pipe |

| Certification | ISO9001 |

| Surface Treatment | Galvanized |

Cold rolled square pipe:

1) Size: different sizes according to customers' requirement

2) Grade: many different kinds of materials.

3) Standard: GB50205-2001, JIS, ASTM and EN

4) Detailed requirement please feel free to contact

5)Specification:GB6728,DIN,JIS,ASTM-A500

6).Grade:Q195,Q235,Q345,ST37-2,ST52-3,SS400,SS355

- Q: What are the advantages of using steel pipes over other materials?

- There are several advantages of using steel pipes over other materials: 1. Strength and Durability: Steel pipes are known for their exceptional strength and durability. They can withstand high pressure, heavy loads, and extreme weather conditions, making them suitable for various applications, including transportation of fluids and gases, structural support, and underground pipelines. 2. Corrosion Resistance: Steel pipes can be coated with different materials to enhance their resistance to corrosion. This makes them suitable for transporting water, chemicals, and other corrosive substances without the risk of pipe degradation. Additionally, steel pipes are less susceptible to rust, which prolongs their lifespan. 3. Cost-effectiveness: Although steel pipes may have a higher upfront cost compared to other materials, they offer long-term cost-effectiveness. Due to their durability and resistance to corrosion, steel pipes require less maintenance and replacement, resulting in reduced operational costs over time. 4. Versatility: Steel pipes come in various sizes, shapes, and thicknesses, making them versatile for different applications. They can be easily customized and fabricated to meet specific requirements, such as bending, welding, and threading. 5. Fire Resistance: Steel pipes have a high melting point, making them resistant to fire and reducing the risk of structural damage during a fire incident. This characteristic is particularly important in industries where fire safety is crucial, such as oil and gas, chemical, and construction. 6. Eco-friendly: Steel is a recyclable material, and steel pipes can be recycled and reused multiple times without compromising their quality. This not only reduces the demand for new materials but also contributes to environmental sustainability. 7. Excellent Flow Characteristics: Steel pipes provide smooth internal surfaces, minimizing friction and allowing for efficient flow of fluids and gases. This advantage is particularly significant in industries where fluid dynamics and energy efficiency are essential, such as oil and gas, water supply, and HVAC systems. In conclusion, steel pipes offer numerous advantages over other materials, including strength, durability, corrosion resistance, cost-effectiveness, versatility, fire resistance, eco-friendliness, and excellent flow characteristics. These advantages make steel pipes the preferred choice for a wide range of applications in various industries.

- Q: How are steel pipes used in the manufacturing of shipbuilding and offshore structures?

- Steel pipes are essential components in the manufacturing of shipbuilding and offshore structures. They are widely used due to their strength, durability, and resistance to corrosion, making them ideal for the harsh marine environment. In shipbuilding, steel pipes are used for various purposes. One of the main applications is in the construction of the hull, the framework that provides structural support to the ship. Steel pipes are used to form the keel and the frames, which help to maintain the shape and strength of the hull. These pipes are welded together to create a robust and rigid structure that can withstand the forces exerted on the ship during navigation. Moreover, steel pipes are used in the construction of various systems onboard the ship. For instance, they are utilized in the piping system for transporting fluids like fuel, water, and oil throughout the vessel. Steel pipes are also employed in the ventilation and air conditioning systems, ensuring proper airflow and temperature control within the ship. In offshore structures, such as oil rigs and platforms, steel pipes play a crucial role. These structures are typically subjected to extreme environmental conditions, including severe weather, high pressure, and corrosive saltwater. Steel pipes are used to fabricate the legs, risers, and other load-bearing components of offshore structures. These pipes provide the necessary strength and stability, allowing the structure to withstand the forces exerted by waves, wind, and drilling operations. Additionally, steel pipes are utilized in the construction of subsea pipelines. These pipelines are used to transport oil, gas, and other fluids from offshore drilling sites to onshore facilities. Steel pipes are preferred due to their high tensile strength and ability to withstand the high pressure and corrosive conditions found in subsea environments. Overall, steel pipes are indispensable in the manufacturing of shipbuilding and offshore structures. Their exceptional strength, durability, and corrosion resistance make them the preferred choice for constructing hulls, systems, and load-bearing components. Without steel pipes, the construction of ships and offshore structures would be significantly compromised in terms of safety, reliability, and longevity.

- Q: How do you determine the weight per foot of a steel pipe?

- To determine the weight per foot of a steel pipe, you need to consider two main factors: the thickness and the diameter of the pipe. First, you need to measure the outer diameter (OD) and the wall thickness (WT) of the pipe using a caliper or a measuring tape. Once you have these measurements, you can calculate the inner diameter (ID) by subtracting twice the wall thickness from the outer diameter (ID = OD - 2 * WT). Next, use the formula for the cross-sectional area of a pipe (A = π * (OD^2 - ID^2) / 4) to calculate the cross-sectional area. Finally, multiply the cross-sectional area by the density of the steel, which is typically around 490 pounds per cubic foot, to determine the weight per foot of the steel pipe. Weight per foot (WPF) = A * 490 It's important to note that this calculation provides an estimate of the weight per foot, as manufacturing tolerances and slight variations in the density of the steel may affect the actual weight. Therefore, it is recommended to use this calculation as a guide and consult the manufacturer's specifications for more precise information.

- Q: What are the advantages of using steel pipes in the manufacturing of storage tanks?

- There are several advantages of using steel pipes in the manufacturing of storage tanks. Firstly, steel pipes are known for their strength and durability, making them suitable for holding large volumes of liquids or gases. They can withstand high pressure and extreme weather conditions, ensuring the longevity of the storage tank. Additionally, steel pipes are resistant to corrosion, which is crucial for preventing leaks or contamination of the stored materials. Moreover, steel pipes can be easily welded, allowing for efficient and precise construction of storage tanks. Finally, steel pipes have a high recyclability rate, making them an environmentally friendly choice for storage tank manufacturing.

- Q: How to establish a concrete-filled steel tubular column model in ANSYS?

- A two unit model or a composite unit model can be adoptedTwo units are constructed of steel tubes and concreteA composite unit may be either a fiber element or a section conversion attribute

- Q: Are steel pipes suitable for wastewater treatment plants?

- Yes, steel pipes are suitable for wastewater treatment plants. Steel pipes are commonly used in wastewater treatment plants due to their high strength and durability. They can withstand high pressure and are resistant to corrosion, making them ideal for carrying wastewater and other fluids in the harsh conditions found in treatment plants. Additionally, steel pipes can be easily welded and joined, allowing for flexibility in the design and installation of the piping system. Overall, steel pipes are a reliable and cost-effective choice for wastewater treatment plants.

- Q: Can steel pipes be used for transporting gases?

- Yes, steel pipes can be used for transporting gases. Steel pipes are known for their strength, durability, and resistance to corrosion, making them an ideal choice for transporting various gases over long distances. Additionally, steel pipes can handle high pressure and extreme temperatures, ensuring the safe and efficient transportation of gases.

- Q: What's the difference between hot-rolled seamless steel tube and cold-rolled seamless steel tube?

- Cold rolled seamless steel pipe (DIAL) in general, steel pipe for low and medium pressure boiler tube, high-pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, oil cracking tube and other steel tube, including carbon thin-walled steel, alloy thin-walled steel, stainless steel, thin steel tube.

- Q: How are steel pipes repaired if they are damaged?

- Steel pipes can be repaired if they are damaged through various methods such as welding, patching, or using pipe clamps.

- Q: Welded and seamless steel pipe how to distinguish?

- Generally, careful observation, can see traces of the weld seam pipe, further is the determination of the polished incision, and then with the file can be seen there is no clear cut, interface traces with the file cleanup to remove when cutting was pasted interface.

Send your message to us

Square Steel Pipe from Okorder in China with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1111 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords