Square Steel Billets Hot Sale Deformed Billet Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

1.M.S. Billets

2.CRS Billets

3.Special Alloy Billets

Festures of steel billet:

Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products. Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

Specifications of steel billet:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

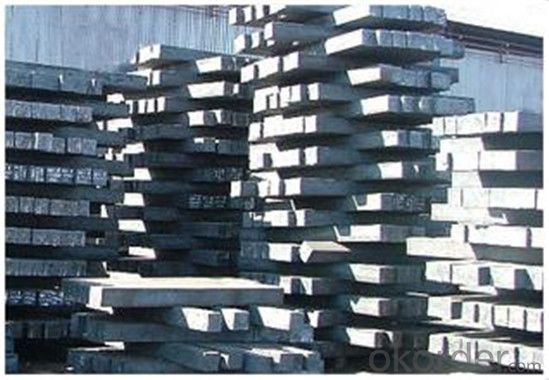

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the advantages of using steel wire rod compared to other materials?

- There are several advantages of using steel wire rod compared to other materials. Firstly, steel wire rod offers superior strength and durability. Steel is known for its high tensile strength, which means it can withstand heavy loads and resist deformation. This makes it an ideal material for various applications that require strong and reliable support, such as in construction, manufacturing, and transportation industries. Secondly, steel wire rod has excellent flexibility. Its elasticity allows it to bend and twist without breaking, making it suitable for applications that require dynamic movement or vibrations, such as in suspension systems, springs, and wire ropes. This flexibility also makes it easier to handle and install in various settings. Additionally, steel wire rod is highly resistant to corrosion. It can withstand exposure to moisture, chemicals, and extreme weather conditions without rusting or deteriorating. This resistance to corrosion makes steel wire rod a long-lasting and low-maintenance option, reducing the need for frequent replacements and repairs. Moreover, steel wire rod is readily available and cost-effective. Steel is one of the most commonly used materials worldwide, which means it is readily available in various shapes, sizes, and grades. This availability makes it easy to source and procure steel wire rod, reducing lead times and costs associated with production. Furthermore, steel's recyclability makes it a sustainable and environmentally-friendly choice. Lastly, steel wire rod offers versatility in terms of its applications. It can be used in a wide range of industries and settings, such as in construction, automotive, aerospace, agriculture, and telecommunications. Its adaptability and compatibility with various manufacturing processes make it a go-to material for many engineering and construction projects. In conclusion, the advantages of using steel wire rod compared to other materials include its superior strength, flexibility, corrosion resistance, availability, cost-effectiveness, and versatility. These qualities make steel wire rod a reliable and efficient choice for a wide range of applications.

- Q: What are the different quality control measures for steel wire rod production?

- To ensure the quality and conformity of steel wire rods to industry standards, various quality control measures are implemented during production. These measures include: 1. Thoroughly analyzing the chemical composition of the steel wire rods to ensure it meets specified requirements. This is typically done using techniques like spectrometry to identify impurities or elements that may affect the wire rod's properties. 2. Close monitoring of dimensions, including diameter and length, using precision instruments and gauges to ensure they meet required specifications and tolerances. 3. Visual inspection of the surface of the wire rods to identify defects such as cracks or scratches. Optical or visual inspection techniques are used to ensure a smooth and defect-free surface. 4. Conducting mechanical tests, such as tensile testing, hardness testing, and impact testing, to evaluate the strength and other mechanical properties of the wire rods. 5. Using non-destructive testing techniques like ultrasonic testing or magnetic particle inspection to identify any internal defects or discontinuities in the wire rods. 6. Closely monitoring and controlling heat treatment processes, such as annealing or quenching, to ensure the wire rods achieve the desired hardness, strength, and microstructure. 7. Ensuring proper packaging and labeling to protect the wire rods during transportation and storage. This includes using suitable packaging materials and techniques to prevent damage or corrosion, and accurate labeling to provide necessary information about the wire rods' specifications and quality. By implementing these quality control measures throughout the production process, steel wire rods can consistently meet the required standards and specifications, providing customers with reliable products for their various applications.

- Q: What are the main factors affecting the product innovation of steel wire rod?

- The main factors affecting the product innovation of steel wire rod include technological advancements, market demand, competition, government regulations, and environmental sustainability. Technological advancements play a crucial role in enhancing the quality, strength, and durability of steel wire rod. Market demand and competition drive manufacturers to continuously innovate and develop new products to meet customer needs and stay ahead in the market. Government regulations, such as safety standards and environmental regulations, also influence product innovation by setting requirements and guidelines that manufacturers must adhere to. Lastly, the focus on environmental sustainability has prompted the steel industry to develop innovative and eco-friendly products and processes, leading to further innovation in steel wire rod.

- Q: What is the difference between hot rolled and cold drawn steel wire rod?

- Various industries use hot rolled and cold drawn steel wire rods for different purposes. The manufacturing process is where the main distinction lies. Hot rolled steel wire rods undergo production by heating a billet or ingot to a high temperature. They are then rolled through a series of rollers to achieve the desired shape and dimensions. As a result, they have a larger diameter and a rougher surface finish. Construction, automotive, and machinery sectors commonly utilize hot rolled steel wire rods due to their strength and durability. Additionally, they are more cost-effective than cold drawn wire rods. In contrast, cold drawn steel wire rods are manufactured by pulling the hot rolled wire rod through a series of dies at room temperature. This process produces a smaller diameter and a smoother surface finish compared to hot rolled wire rods. Cold drawn wire rods are frequently used in applications that require precision and a smooth surface finish. Examples include the manufacturing of precision components, automotive parts, and electrical conductors. To summarize, the manufacturing process is the main factor that distinguishes hot rolled and cold drawn steel wire rods. This process affects the diameter, surface finish, and suitability for different applications. Hot rolled wire rods have a larger diameter and a rougher surface finish, while cold drawn wire rods have a smaller diameter and a smoother surface finish. The choice between the two depends on the specific requirements of the application, such as strength, precision, and surface finish.

- Q: What are the different tensile strengths available for steel wire rod?

- The tensile strengths available for steel wire rod vary depending on the specific grade and composition of the steel. Common tensile strengths for steel wire rod range from 400 MPa (megapascals) to 1200 MPa, with some specialty grades reaching even higher strengths.

- Q: How are steel wire rods used in the manufacturing of wire brushes for cleaning purposes?

- Wire brushes for cleaning purposes require steel wire rods as an essential component. These rods are typically crafted from high-quality steel, renowned for its strength, durability, and flexibility. To produce wire brushes, the steel wire rods undergo a series of procedures. Initially, the wire rods are carefully chosen based on their composition and tensile strength. Next, they are fed through a wire drawing machine, which reduces their diameter and elongates their length. This process allows for the creation of slender and lengthy wires, perfect for brush bristles. Once the wires are drawn, they are straightened and cut to the desired length, which may vary depending on the brush type. The straightened wires are then either inserted into a metal ferrule or twisted together to form a bundle, depending on the brush design. The wire bristles are subsequently affixed to a handle or base, which can be crafted from wood, plastic, or metal. This assembly procedure can be performed manually or with the assistance of specialized machinery. The bristles are securely fastened to prevent them from coming loose during use. Steel wire rods are favored for manufacturing wire brushes due to their outstanding cleaning properties. The strength and flexibility of steel enable the bristles to effectively eliminate dirt, grime, and debris from various surfaces. They are suitable for use on a wide range of materials, including metal, wood, and concrete. Wire brushes made from steel wire rods are commonly employed for cleaning tasks such as rust removal, paint stripping, and corrosion elimination from surfaces. They are also utilized in preparing surfaces for painting or welding, cleaning welding joints, and scrubbing hard-to-reach areas. These brushes find applications in industries like automotive, manufacturing, construction, and maintenance. To summarize, steel wire rods are vital in the production of wire brushes for cleaning purposes. Their strength, durability, and flexibility make them ideal for crafting efficient and dependable cleaning tools. Whether it involves rust removal, weld cleaning, or surface scrubbing, wire brushes made from steel wire rods are indispensable in numerous industries and households.

- Q: What are the different types of steel wire rod finishes available?

- There are several types of steel wire rod finishes available, including black, galvanized, and coated finishes. Black finish refers to untreated steel wire rods that have a natural dark gray or black appearance. Galvanized finish involves applying a protective zinc coating to the steel wire rods to prevent corrosion. Coated finishes, on the other hand, involve applying a layer of polymer or other materials to enhance the wire rod's properties, such as lubricity or resistance to wear and tear.

- Q: What are the common production processes for seaborgium-coated steel wire rod?

- The common production processes for seaborgium-coated steel wire rod typically involve several steps. Firstly, the steel wire rod is cleaned and prepared through processes like pickling and surface grinding to remove any impurities or oxides. Then, a layer of seaborgium is applied onto the steel wire rod using techniques like electroplating or physical vapor deposition. This ensures a uniform and durable coating on the surface. Finally, the coated steel wire rod undergoes quality control checks to ensure that the seaborgium coating meets the required specifications before it is ready for further applications.

- Q: What are the major challenges faced by the steel wire rod industry?

- Today's market presents several major challenges for the steel wire rod industry. Among these challenges, the fluctuation in raw material prices, particularly iron ore and coal, stands out. The production of steel wire rods heavily relies on these inputs, and any significant price increase can have a substantial impact on the overall cost of production. Additionally, the industry faces intense global competition, both domestically and internationally. To stay competitive, steel wire rod manufacturers must constantly improve their production efficiency, reduce costs, and enhance product quality. Moreover, the industry must address environmental regulations and sustainability concerns. The energy-intensive processes involved in steel wire rod production can lead to high carbon emissions. To meet the increasing demand for sustainability, manufacturers must invest in cleaner technologies and adopt eco-friendly practices to reduce their carbon footprint. Furthermore, fluctuating demand for steel wire rods poses a challenge. The demand for these rods in sectors such as construction, automotive, and manufacturing is subject to economic cycles and external factors. Manufacturers must closely monitor market trends and adjust their production accordingly to avoid overproduction or underutilization of capacity. In addition, technological advancements present a challenge for the industry. With the rise of automation and digitalization, steel wire rod manufacturers must invest in advanced technologies to improve production efficiency, reduce downtime, and enhance product quality. However, this requires significant capital investment and skilled labor, which can be a challenge for some companies. Finally, the industry must address the issue of counterfeit products. Counterfeit steel wire rods can pose safety risks to end-users. Manufacturers must implement strict quality control measures and collaborate closely with regulatory authorities to prevent the circulation of counterfeit products in the market. In conclusion, the steel wire rod industry is confronted with challenges such as fluctuating raw material prices, intense global competition, environmental regulations, fluctuating demand, technological advancements, and the issue of counterfeit products. Overcoming these challenges necessitates continuous innovation, strategic planning, and a focus on sustainability to ensure the long-term success of the industry.

- Q: How are steel wire rods used in the manufacturing of wire ropes?

- Steel wire rods are an essential component in the manufacturing of wire ropes. These wire rods serve as the raw material for producing the individual wires that are twisted together to form the rope. The first step in the manufacturing process involves drawing the steel wire rods through a series of dies to reduce their diameter and increase their length. This process is known as wire drawing and results in wires of different sizes and strengths. Once the desired wires are obtained, they are then twisted together in a specific pattern to form strands. These strands are typically twisted in a helical manner around a core, which can be another wire or a fiber material. The number of strands and the direction of the twist depend on the intended use and load requirements of the wire rope. The steel wire rods used in this process are specifically chosen for their high tensile strength, durability, and resistance to corrosion. Steel is known for its excellent strength-to-weight ratio, making it ideal for applications requiring reliable and robust wire ropes. Moreover, the quality of the steel wire rods plays a crucial role in determining the performance and longevity of the wire rope. The steel must meet stringent specifications to ensure that it can withstand heavy loads, extreme weather conditions, and repetitive stress without compromising the integrity of the wire rope. In conclusion, steel wire rods are transformed into wires through wire drawing and subsequently used in the manufacturing of wire ropes. These wire ropes find applications in various industries, such as construction, mining, maritime, and transportation, where they are relied upon for their strength, durability, and ability to withstand demanding conditions.

Send your message to us

Square Steel Billets Hot Sale Deformed Billet Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords