Square Steel Billets Hot Sale Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Type | Steel billet / Square steel/ Steel square bar |

Standard grade | 3SP/PS, 5SP/PS, Q195, Q235, Q255, Q275, 20MnSi etc. |

MOQ | 1000 MT |

Technique | Hot rolled |

Size | 50*50mm ~ 160*160mm |

Length | 3~12m |

Packing | Loose packing, in bundle |

Payment terms | T/T, L/C at sight, Usance L/C |

Trade terms | EXW, FOB, CFR, CIF |

Trans terms | FIO, FILO, FLT |

Inspection | Third party inspection accepted |

Delivery time | 15-30 days, according to the quantity |

Applications | carbon structural steel, wire rod, rod, deformed bars, profile steel, machine parts, and steel moulds etc . |

Note | Customized service is available (for sizes,length and chemical components etc.). |

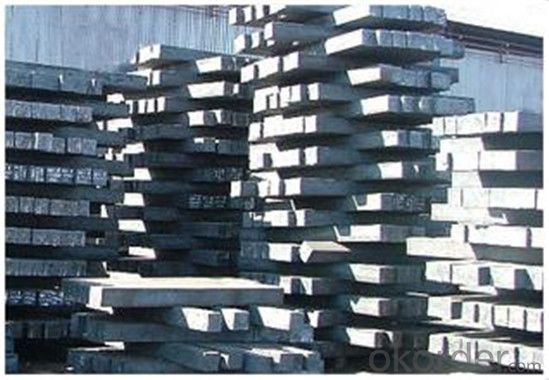

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the main factors influencing the choice of steel wire rod coating?

- The main factors influencing the choice of steel wire rod coating include the intended application, environmental conditions, durability requirements, and cost considerations. Firstly, the intended application of the steel wire rod is crucial in determining the appropriate coating. Different coatings provide specific properties such as corrosion resistance, lubricity, or electrical conductivity. For example, if the steel wire rod is intended for outdoor use or exposure to moisture, a corrosion-resistant coating such as zinc or zinc-aluminum is preferred. On the other hand, if the wire rod is used for electrical purposes, a coating with high electrical conductivity may be necessary. Secondly, the environmental conditions in which the steel wire rod will be used also play a significant role in the choice of coating. Factors like temperature, humidity, exposure to chemicals, and UV radiation can impact the performance and durability of the coating. Therefore, coatings that offer excellent resistance to these environmental factors are often selected. Durability requirements are another influential factor. Depending on the intended lifespan of the wire rod and the level of wear and tear it will experience, different coatings with varying levels of durability may be chosen. Some coatings, such as epoxy or polyurethane, provide excellent resistance to abrasion and impact, making them suitable for applications that involve frequent handling or rough environments. Lastly, cost considerations are an important factor in the choice of steel wire rod coating. Different coatings have different price points, and the cost must be balanced with the desired performance and durability. It is essential to choose a coating that meets the requirements at a reasonable cost, ensuring a cost-effective solution without compromising the performance of the wire rod. In conclusion, the choice of steel wire rod coating is influenced by the intended application, environmental conditions, durability requirements, and cost considerations. By considering these factors, manufacturers can select the most suitable coating that provides the necessary properties and durability for the specific application while being cost-effective.

- Q: What are the different types of steel wire rod finishes for improved heat resistance?

- Some of the different types of steel wire rod finishes for improved heat resistance include galvanized, phosphate, and copper-coated finishes. These finishes provide a protective layer on the surface of the wire rod, enhancing its ability to withstand high temperatures and resist corrosion.

- Q: What are the common production processes for dubnium-coated steel wire rod?

- The common production processes for dubnium-coated steel wire rod typically involve several steps. First, the steel wire rod is cleaned and prepared to remove any impurities. Then, a layer of dubnium coating is applied to the surface of the wire rod using methods such as electroplating or physical vapor deposition. This coating process helps enhance the wire rod's corrosion resistance, durability, and other desired properties. Finally, the dubnium-coated steel wire rod undergoes quality control inspections to ensure it meets the required standards before being made available for various applications.

- Q: How is steel wire rod used in the production of wire ropes for mining applications?

- Steel wire rod is used as the primary raw material in the production of wire ropes for mining applications. It serves as the foundation for creating the wire strands that make up the rope. The wire rod is first cleaned and coated to enhance its durability and resistance to corrosion. It is then drawn through a series of dies to reduce its diameter and increase its strength. These drawn wires are then twisted or braided together to form the wire strands, which are further assembled into wire ropes used in mining operations. The high strength and resilience of steel wire rod make it a crucial component in ensuring the safety and reliability of wire ropes used in demanding mining conditions.

- Q: How is steel wire rod used in the manufacturing of wire for agricultural fencing?

- Steel wire rod is used in the manufacturing of wire for agricultural fencing by being drawn through a series of dies to reduce its diameter and increase its length. This process, known as wire drawing, results in a strong and durable wire that is then woven or welded into the desired fencing shape. The high tensile strength of steel wire rod ensures that the agricultural fencing can withstand the pressure and stress it may encounter in outdoor environments, making it an ideal material for securing livestock and crops.

- Q: How are steel wire rods used in the production of fishing lines for catching fish?

- Steel wire rods are a crucial component in the production of fishing lines for catching fish. These wire rods are used to create the core of the fishing line, providing strength and durability necessary to withstand the tension and pressure exerted by large fish during the catching process. To manufacture fishing lines, the steel wire rods undergo a series of processes. Firstly, the rods are drawn through a series of dies to reduce their diameter and increase their length. This process, known as wire drawing, results in thinner and longer wire rods, which are easier to handle and work with during the production of fishing lines. Once the wire rods are drawn, they are coated with a layer of protective material, such as nylon or polyethylene, to enhance their resistance to abrasion, UV rays, and water damage. This coating also improves the overall flexibility and knot strength of the line, making it more reliable for fishing purposes. After the coating process, the steel wire rods are then twisted or braided together to form the fishing line. The number of wire rods used and the specific twisting or braiding technique employed varies depending on the desired strength, thickness, and characteristics of the fishing line. The resulting fishing line is known for its exceptional strength, durability, and resistance to breakage. It can withstand the harsh conditions of fishing, such as sharp rocks, strong currents, and the thrashing of fish, without losing its integrity. This makes it an essential tool for anglers, enabling them to confidently target and catch a wide variety of fish species. In summary, steel wire rods are integral to the production of fishing lines as they provide the necessary strength and durability required for successful fish catching. The wire rods are drawn, coated, twisted, or braided together to create fishing lines that are strong, flexible, and resistant to the elements, allowing anglers to enjoy a reliable and efficient fishing experience.

- Q: How is steel wire rod used in the production of wire hangers?

- Steel wire rod is used as the main raw material in the production of wire hangers. It is first shaped and cut into the desired length to form the hanger's body. The wire rod's strength and flexibility make it ideal for supporting the weight of garments without bending or breaking. Additionally, the rod can be coated or plated to enhance durability and prevent rusting. Overall, steel wire rod plays a crucial role in ensuring the sturdiness and functionality of wire hangers.

- Q: What are the major players in the global steel wire rod market?

- Some major players in the global steel wire rod market include ArcelorMittal, Nippon Steel Corporation, Gerdau S.A., Tata Steel Ltd., and POSCO. These companies are known for their strong presence, extensive product portfolios, and global reach within the industry.

- Q: How are steel wire rods used in the manufacturing of bicycle spokes for strength and flexibility?

- Steel wire rods are used in the manufacturing of bicycle spokes to provide strength and flexibility. The high tensile strength of steel allows the spokes to withstand the weight and stress exerted on them while riding. Additionally, the flexibility of steel wire rods allows the spokes to absorb shocks and vibrations, contributing to a smoother and more comfortable ride.

- Q: How is steel wire rod used in the manufacturing of coat hangers?

- Due to its strength and flexibility, steel wire rod plays a vital role in the production of coat hangers. Initially, the steel wire rod undergoes a series of drawing processes to decrease its diameter and increase its tensile strength. This process yields a lengthy, continuous wire that can be easily manipulated and shaped. To construct the frame of the coat hanger, specialized machinery is used to bend and twist the steel wire rod into the desired shape. The wire can be manipulated to form the main body of the hanger, as well as the hook and any additional features like trouser clips or notches for straps. The robustness of the steel wire rod ensures that the coat hanger can bear the weight of heavy garments without bending or breaking. Once the wire frame is formed, it is frequently coated with a protective layer to enhance its appearance and prevent rust. This coating may consist of paint, plastic, or even a thin layer of chrome. Not only does the coating provide an attractive finish, but it also safeguards the steel wire rod from corrosion, extending the lifespan of the coat hanger. In summary, steel wire rod is indispensable in the manufacture of coat hangers due to its capacity to offer the necessary strength, flexibility, and durability required to support various garment types. Its versatility allows for the creation of diverse hanger designs while ensuring they can endure the weight and strain of suspended clothing.

Send your message to us

Square Steel Billets Hot Sale Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords