Square Steel Billet Hot Sale Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Name: | steel billets |

LENGTH: | 6 meter to 12 meter (+ 50mm) |

Size: | 100*100, 120*120, 150*150, 200*200 |

Grade: | 3SP,5SP,Q235,20MnSi. |

Shape: | Square, Round |

Technique: | Hot-Rolled |

Standard: | ASTM/GB |

BENDING | No more than 5mm in 1 meter |

ANGULAR TWIST | No more than 1 degree per meter and not more than 6 degree over 12 meter length. |

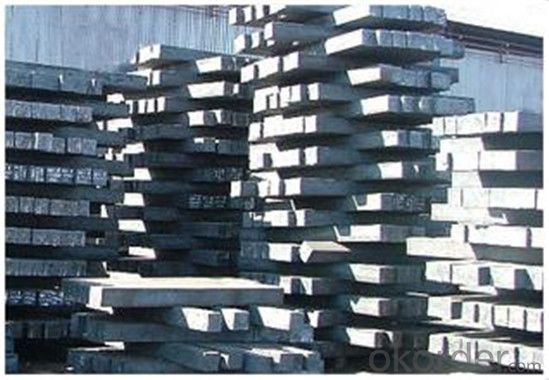

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the main factors affecting the toughness of steel wire rod?

- The main factors affecting the toughness of steel wire rod include the composition of the steel, the heat treatment process, the presence of impurities or defects, and the wire rod's microstructure.

- Q: What are the common material specifications for steel wire rod?

- Some common material specifications for steel wire rod include the type of steel used (such as carbon steel or alloy steel), the diameter or gauge of the wire rod, the tensile strength, and the chemical composition of the steel (including elements like carbon, manganese, and silicon). Other specifications may include surface condition, surface quality, and any specific industry standards or certifications required.

- Q: What are the main factors influencing the choice of steel wire rod order tracking system?

- The main factors influencing the choice of a steel wire rod order tracking system include the size and complexity of the supply chain, the volume and variety of orders, the need for real-time visibility and tracking, the integration with other systems, the availability of data analytics and reporting capabilities, and the cost and scalability of the system.

- Q: How is steel wire rod used in the manufacturing of wire for springs in mattresses?

- Steel wire rod is an essential raw material used in the manufacturing of wire for springs in mattresses. It serves as the building block for creating sturdy and durable springs. The steel wire rod undergoes a series of processes such as drawing, annealing, and tempering to enhance its strength and flexibility. These processed rods are then coiled and formed into springs, which are ultimately incorporated into the mattresses to provide support and enhance comfort.

- Q: How is steel wire rod used in the manufacturing of wire mesh conveyor belts?

- Steel wire rod is used in the manufacturing of wire mesh conveyor belts as it serves as the base material for creating the wire mesh. The steel wire rod is drawn and shaped into individual wires that are then woven together to form the mesh pattern of the conveyor belt. This process helps to provide strength, durability, and flexibility to the belt, making it suitable for various industrial applications such as conveying heavy loads or high-temperature materials.

- Q: How is steel wire rod packaged for transportation?

- Steel wire rod is typically packaged for transportation in a variety of ways, depending on the specific requirements of the customer and the mode of transportation being used. One common method of packaging steel wire rod is by using coils. The wire rod is wound tightly around a central core, creating a coil that is easy to handle and transport. These coils can vary in size and weight, depending on the specific needs of the customer and the transportation method being used. Coils are often wrapped in protective materials, such as plastic or paper, to prevent damage during transportation. In addition to coils, steel wire rod can also be packaged in bundles. Bundles are typically made up of a certain number of individual rods that are securely bound together using straps or wire. This type of packaging is often used for larger quantities of wire rod, as it allows for easier handling and loading onto trucks or shipping containers. Bundles are also typically protected with some form of wrapping material to prevent damage during transportation. When it comes to shipping steel wire rod internationally, it may be necessary to use containers for transportation. In this case, the wire rod can be loaded into containers either as coils or bundles, depending on the preference of the customer and the efficiency of loading and unloading at the destination. Overall, the packaging of steel wire rod for transportation is designed to ensure the safe and efficient delivery of the product to the customer. It takes into account factors such as the quantity of wire rod being transported, the mode of transportation being used, and the specific requirements of the customer. By using coils, bundles, or containers, steel wire rod can be securely packaged for transportation, minimizing the risk of damage and ensuring the product arrives in its desired condition.

- Q: What are the major barriers to entry in the steel wire rod market?

- The major barriers to entry in the steel wire rod market include high capital requirements for setting up production facilities, the need for advanced technology and expertise, significant economies of scale enjoyed by existing players, and the presence of established distribution networks. Additionally, stringent industry regulations and the need for extensive quality certifications can also pose challenges for new entrants.

- Q: What are the safety considerations for handling steel wire rod?

- Some safety considerations for handling steel wire rod include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. It is also important to ensure proper lifting techniques are used to prevent strains or back injuries. Additionally, workers should be trained on the proper handling and storage procedures to avoid accidents caused by improper stacking or movement of the rods. Regular inspections of the wire rods and equipment should be conducted to identify any potential hazards or defects that could compromise safety.

- Q: What are the main factors influencing the choice of steel wire rod order cancellation policy?

- The choice of cancellation policy for steel wire rod orders is influenced by several key factors. These factors include market conditions, manufacturing lead time, cost implications, customer relationships, and legal and contractual obligations. 1. Market conditions: The cancellation policy is determined by the current state of the market. If there is high demand and limited supply, the policy may be stricter to maintain a smooth supply chain. Conversely, if the market is experiencing a downturn with low demand, the policy may be more flexible to accommodate changes in customer requirements. 2. Manufacturing lead time: The lead time required to produce steel wire rods is an important consideration for the cancellation policy. If the lead time is long, the policy may be more stringent to avoid unnecessary production or inventory costs caused by cancellations. On the other hand, if the lead time is short, the policy may be more flexible as adjustments to the production schedule can be made quickly. 3. Cost implications: The cancellation policy takes into account the costs associated with cancelling an order. This includes costs related to raw material procurement, production setup, and storage. If the cancellation costs are high, the policy may be more strict to minimize financial losses for the manufacturer. 4. Customer relationships: The nature of the relationship between the manufacturer and the customer can influence the cancellation policy. If there is a long-standing and strong relationship, the manufacturer may be more accommodating to cancellations in order to maintain customer satisfaction and loyalty. Conversely, if the relationship is new or strained, the policy may be stricter to protect the manufacturer's interests. 5. Legal and contractual obligations: Legal and contractual obligations are also important factors in determining the cancellation policy. The manufacturer must ensure compliance with any legal requirements or contractual agreements with the customer. These obligations may dictate the terms and conditions for order cancellations, including any penalties or liabilities. In conclusion, the cancellation policy for steel wire rod orders is shaped by market conditions, manufacturing lead time, cost implications, customer relationships, and legal and contractual obligations. Manufacturers must carefully consider these factors in order to find a balance between meeting customer needs and safeguarding their own interests.

- Q: How is steel wire rod used in the manufacturing of wire for power generation systems?

- Wire rod made of steel is a crucial raw material utilized in the production of wire for power generation systems. It acts as the main material for manufacturing top-quality cables used for transmitting and distributing electricity from power plants to various destinations. The manufacturing process commences by carefully selecting steel wire rod based on its specific properties, such as strength, durability, and conductivity. The rod is then heated to the suitable temperature and passed through a series of dies to shape it into the desired wire diameter. This process, known as wire drawing, involves reducing the rod's diameter while increasing its length. After the wire has been drawn to the required size, it undergoes various treatments to enhance its mechanical properties. These treatments may include annealing, where the wire is heated and gradually cooled to relieve internal stresses and improve its flexibility and ductility. Additionally, the wire may be galvanized, which involves applying a protective layer of zinc to prevent corrosion and prolong its lifespan. The manufactured wire is then utilized in the construction of power transmission and distribution cables. These cables play a crucial role in efficiently and safely delivering electricity over long distances. The steel wire provides the necessary strength and tensile properties to support the cables' weight and withstand the mechanical stresses during installation and operation. It also ensures that the cables maintain their shape and structure even when subjected to external forces like wind, ice, and temperature changes. Furthermore, the electrical conductivity of the steel wire allows for efficient transmission of electricity, reducing power losses during transmission. This property is particularly important in power generation systems, where minimizing energy losses is vital for the effective and economical delivery of electricity. In conclusion, steel wire rod is an indispensable component in the production of wire for power generation systems. It possesses the required mechanical strength, durability, and electrical conductivity needed for power transmission and distribution cables. By enabling efficient and reliable electricity transmission, steel wire plays a crucial role in powering our homes, businesses, and industries.

Send your message to us

Square Steel Billet Hot Sale Q275/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords