Square Steel Billets Hot Sale 3SP/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of steel billet:

Our company is recognized by ISO9001:2008

1. hot rolled wire rod

2. material: Q195-235

Festures of steel billet:

1. Drawn wire specialist, your wire rod solution

2. ISO9001 Certified Mill &SGS

3. Feature: machinability, high hardness, toughness, corrosion resistant

Specifications of steel billet:

Size | 60*60/90*90/100*100/120*120/150*150 |

Length | 6000mm-12000mm |

Standard | GB |

Applicaton | To produce bars or other applications |

Grade | Q195/Q235/Q275/3SP/5SP/20MnSi |

Packing terms | TT/LC |

Package | Mill's standard packing or as client's requirment |

Delivery time | Within 10-30 days after receiving the deposit or LC |

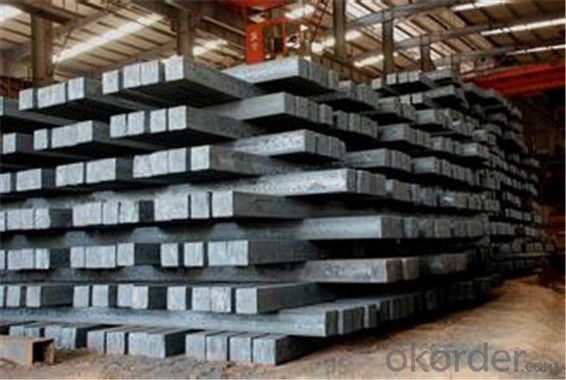

Images of steel billet:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How is steel wire rod used in the manufacturing of wire for automotive seat frames?

- Steel wire rod is used in the manufacturing of wire for automotive seat frames as it serves as the primary raw material for producing the wire. The steel wire rod is first processed through various mechanical and heat treatment processes to enhance its strength and durability. Once transformed into wire form, it is further used to fabricate the intricate seat frame structures, providing strength and support to ensure safety and comfort for automotive passengers.

- Q: How is steel wire rod used in the production of wire baskets and containers?

- Steel wire rod is a crucial component in the production of wire baskets and containers. It is primarily used as the raw material for manufacturing the wires that form the framework of these baskets and containers. The production process begins with the steel wire rod being loaded onto a wire drawing machine, where it is pulled through a series of dies to reduce its diameter and increase its length. This process, known as wire drawing, results in the formation of long, thin wires that are strong and flexible. These wires are then further processed to create the desired shape and size for the wire baskets and containers. They are bent, twisted, and welded together to form a sturdy and durable framework. The steel wire rod provides the necessary strength and rigidity to withstand the weight and pressure exerted on the baskets and containers during use. In addition to providing structural support, steel wire rod also contributes to the overall aesthetics of wire baskets and containers. It can be coated or treated to enhance its appearance, making it more visually appealing. This makes steel wire rod a versatile material that can be customized to meet specific design requirements. Overall, steel wire rod plays a vital role in the production of wire baskets and containers by providing the necessary strength, durability, and versatility required for these products. It serves as the building block that creates the framework and structure, ensuring that the baskets and containers are functional, long-lasting, and visually appealing.

- Q: How is steel wire rod packaged for transportation?

- Steel wire rod is typically packaged for transportation in a variety of ways, depending on the specific requirements of the customer and the mode of transportation being used. One common method of packaging steel wire rod is by using coils. The wire rod is wound tightly around a central core, creating a coil that is easy to handle and transport. These coils can vary in size and weight, depending on the specific needs of the customer and the transportation method being used. Coils are often wrapped in protective materials, such as plastic or paper, to prevent damage during transportation. In addition to coils, steel wire rod can also be packaged in bundles. Bundles are typically made up of a certain number of individual rods that are securely bound together using straps or wire. This type of packaging is often used for larger quantities of wire rod, as it allows for easier handling and loading onto trucks or shipping containers. Bundles are also typically protected with some form of wrapping material to prevent damage during transportation. When it comes to shipping steel wire rod internationally, it may be necessary to use containers for transportation. In this case, the wire rod can be loaded into containers either as coils or bundles, depending on the preference of the customer and the efficiency of loading and unloading at the destination. Overall, the packaging of steel wire rod for transportation is designed to ensure the safe and efficient delivery of the product to the customer. It takes into account factors such as the quantity of wire rod being transported, the mode of transportation being used, and the specific requirements of the customer. By using coils, bundles, or containers, steel wire rod can be securely packaged for transportation, minimizing the risk of damage and ensuring the product arrives in its desired condition.

- Q: What are the safety requirements for steel wire rod used in mining wire ropes?

- The safety requirements for steel wire rod used in mining wire ropes include high tensile strength, resistance to corrosion and abrasion, proper heat treatment to ensure ductility and toughness, reliable breaking strength, stringent quality control measures, and compliance with industry standards such as ISO and ASTM. Regular inspections, testing, and maintenance are also essential to ensure the safe and reliable operation of mining wire ropes.

- Q: What are the major steel wire rod producing countries?

- The major steel wire rod producing countries include China, Japan, India, and the United States.

- Q: What are the common production processes for zinc-coated steel wire rod?

- The common production processes for zinc-coated steel wire rod include cleaning and pickling the steel wire rod, coating it with a layer of zinc through hot-dip galvanizing or electro-galvanizing, and finally, coiling the zinc-coated wire rod for packaging and transportation.

- Q: What are the different types of steel wire rod surface defect monitoring and reporting systems?

- There are various types of steel wire rod surface defect monitoring and reporting systems, including visual inspection systems, automated optical inspection systems, ultrasonic inspection systems, and electromagnetic inspection systems. These systems utilize different technologies and methods to detect and analyze surface defects on steel wire rods, providing accurate and detailed reports for quality control and process improvement purposes.

- Q: What are the different types of steel wire rod surface defect prevention and control measures?

- There are several types of steel wire rod surface defect prevention and control measures. Some of them include implementing proper cleaning and lubrication processes, using high-quality raw materials, ensuring proper temperature control during the rolling process, conducting regular inspections and tests for defect detection, and implementing effective corrective measures to address any identified defects. Additionally, maintaining a clean and controlled production environment, proper storage and handling of the wire rods, and ensuring skilled and trained operators also contribute to preventing and controlling surface defects in steel wire rods.

- Q: How is steel wire rod used in the production of reinforcement bars?

- Steel wire rod is used in the production of reinforcement bars by being heated and passed through a series of dies to form the desired shape and size. This process, known as hot rolling, helps strengthen the steel wire rod and enhances its ductility, making it suitable for use in reinforcement bars. The reinforcement bars, also known as rebars, are then used to provide strength and support to concrete structures, such as buildings, bridges, and highways, by reinforcing them against tension and bending forces. Overall, steel wire rod plays a vital role in the production of reinforcement bars, ensuring the durability and structural integrity of various construction projects.

- Q: What are the factors that affect the strength of steel wire rod?

- The factors that affect the strength of steel wire rod include the composition of the steel, the manufacturing process used, the heat treatment applied, the presence of impurities or defects, and the level of strain or stress the wire rod is subjected to. Additionally, factors such as the diameter, length, and surface condition of the wire rod can also influence its strength.

Send your message to us

Square Steel Billets Hot Sale 3SP/5SP in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords