Soft/Tight Fibre Cone Textile Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Application:

Soft/Tight Fibre Cone Textile Winding Machine is suitable for winding yarns on cones with even density and soft package before dyeing.

Main features:

Soft/Tight Fibre Cone Textile Winding Machine

1. Vertical yarn path design, no inflection point, yarn friction is small, less hairiness.

2. Special motor with longer axis can prevent yarn twisting, speed controlled by inverter.

3. Double points tension control system with micro motors, uniform yarn tension.

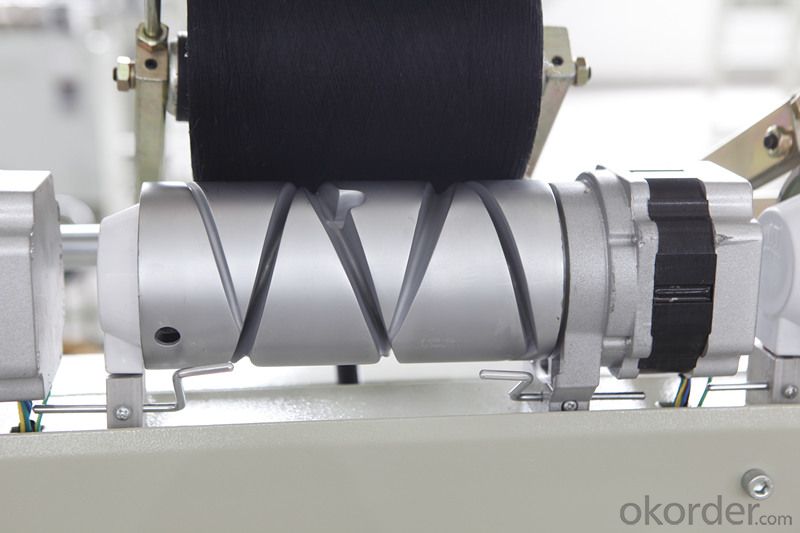

4. Using high quality alloy drums with optimized groove shape, which has the advantages of good anti-overlapping characteristics, light weight, good wear resistance, and static elimination.

5. Single winding motor control for each spindle, electronic length, single spindle automatic stop while yarn breaking or fully filled.

6. High-speed creel with gas spring, which can keep constant winding pressure. This creel is stable and reliable.

7. The traverse device for making the soft edge is very easy to adjust, that will make the loose bobbin be suitable for even dyeing.

8. There is tube conveyor on the machine, it can convey tubes and packing automatically. With it, you can not only save labor, but also keep the production site clean.

9. Our adjustable block yarn sheet metal can prevent the yarn be a mass.

Product pictures of Soft/Tight Fibre Cone Textile Winding Machine:

Delivery Pictures:

Specification:

Soft/Tight Fibre Cone Textile Winding Machine

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 800m/min |

| Package shape | Cylindrical or conical |

| Traverse length | 230mm,280mm, |

| Package bobbin | Cylindrical or conical of 3°30’ |

| package diameter | Up toφ 290 mm |

| Package density | 0.2-0.4g/cm3 |

| Package weight | Up to10kg |

FAQ of Soft/Tight Fibre Cone Textile Winding Machine:

· Q:What is the machine used for?

A: Soft/Tight Fibre Cone Textile Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: How does the mechanical wave generated in the spinning process work?

- The sum bar means that the two columns are superimposed on each other

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- Yuan Dynasty Yuanzhen years, the flow of the state of the Huangdao Po returned home, feel engaged in the hard work of textile women, then its contribution to the improvement of the old textile machinery to become a set of rods, bombs, spinning, weaving The production tool. In addition, she created three foot spinning machine, which can be spinning three yarns at the same time. Tri-spinning car at the time was a very great invention

- Q: Textile machinery industry how to have prospects?

- Foreign-funded enterprises in addition to the equipment for the Chinese market, but also a large number of exports, and even anti-sales back to the country of origin. China is moving from one of the largest textile machinery market demand to Asia Textile Machinery Manufacturing Center, and even the world textile machinery manufacturing center.

- Q: What are the different effects of textile equipment?

- , Low technology content, the process of redundant, such as cotton, to experience spinning, weaving

- Q: What is the chenille mechanical principle?

- Its production and processing products called chenille yarn or spiral, broken wire, is a new variety of fancy

- Q: What are the risks of safety accidents in the textile machinery industry?

- Textile machinery industry is the light industry, mainly to master with high-speed rotating machine production

- Q: Who invented Jenny spinning machine?

- Things start from the day of 1764. England Lancashire has a textile worker James Hargreaves, that night he went home, opened the door after accidentally kicked his wife is using the spinning machine, when his first reaction is to hurry Spinning machine righting. But when he bent down, but suddenly shocked, and he saw that the spinning was spinning the spinning machine is still turning, but the original sideways of the yarn now become upright.

- Q: Why did the first industrial revolution begin with the sign of Jenny's textile machine rather than shuttle?

- But can be called the British industrial revolution began to mark the only 1765 knitting and carpenter Hagrids invented the "Jenny spinning machine"

- Q: What is the textile process?

- , clear cotton process: to remove most of the raw cotton impurities, defects and not spinning short fiber.

- Q: What is the structure and working principle of Jenny's spinning machine?

- The yarn is hooked by the spindle bar was held, the small car on the platen also holds the yarn, spinning rotation wheel to drive the shaft, shaft through the rope rotation spindle, which is the yarn Twist the process. Push the car forward is a stretch process.

Send your message to us

Soft/Tight Fibre Cone Textile Winding Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords