Textiles Winder Drums of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

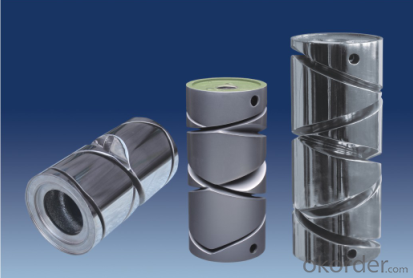

Textiles Winder Drums of Winding Machine Parts

Adavantages:

Textiles Winder Drums of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

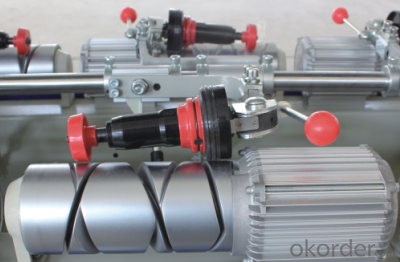

Pictures shows of Textiles Winder Drums of Winding Machine Parts:

Models of Textiles Winder Drums of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Textiles Winder Drums of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Textiles Winder Drums of Winding Machine Parts:

· Q:What is the machine used for?

A:Textiles Winder Drums of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: How to promote the textile machinery industry transformation and upgrading?

- From low production efficiency to high production efficiency, from the provision of product functionality

- Q: When the textile industry, as well as the history of the textile industry development?

- Ancient countries in the world for the textile fibers are natural fibers, usually wool, linen, cotton) three short fibers, such as the Mediterranean region before the textile fiber is only wool and linen; India Peninsula region before the use of cotton

- Q: What are the main producing areas of Chinese textile machinery?

- Yuci textile machinery industry from the last century 50's, state-owned Jingwei Textile Machinery Plant put into operation. "Nine after five, by virtue of the latitude and longitude of the radiation and drive in the Economic and Technological Development Zone, Yuci District, the gradual rise of a private enterprise as the main textile machinery parts production and processing groups.

- Q: Is there a textile industry in the Qin Dynasty?

- Until today, our daily clothing, certain daily necessities and works of art are the products of textile and printing and dyeing technology.

- Q: How is the machine automatically connected to the machine?

- Pick yarn yarn, so that cotton fiber, synthetic fiber and wool fiber and other raw materials of different colors and monochrome warp can be firmly together, so the smooth completion of the process

- Q: What is the history of the development of textile machinery?

- Human beings originally used natural fibers as raw materials for spinning and weaving, earlier than the invention of the text (see World Textile History, China Textile History).

- Q: Is the textile machine made of those accessories?

- The mechanical part of the loom, including the opening, weft insertion, beating, winding, sent by the five major sports institutions, a lot of auxiliary parts, especially the modern loom, mechanical and electrical integration, a high degree of automation

- Q: What are the classification of textile machinery?

- 3. Hydraulic large spinning wheel

- Q: What modern textile machinery?

- Textile machinery is usually classified according to the production process, including: spinning equipment, weaving equipment, printing and dyeing equipment, finishing equipment, chemical fiber spinning equipment, reeling equipment and non-woven equipment

- Q: Textile machinery production process is probably what kind of?

- All kinds of machinery in terms of the principle to the structure has a very big difference.

Send your message to us

Textiles Winder Drums of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords