Cnc Machining Turning Aluminium drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

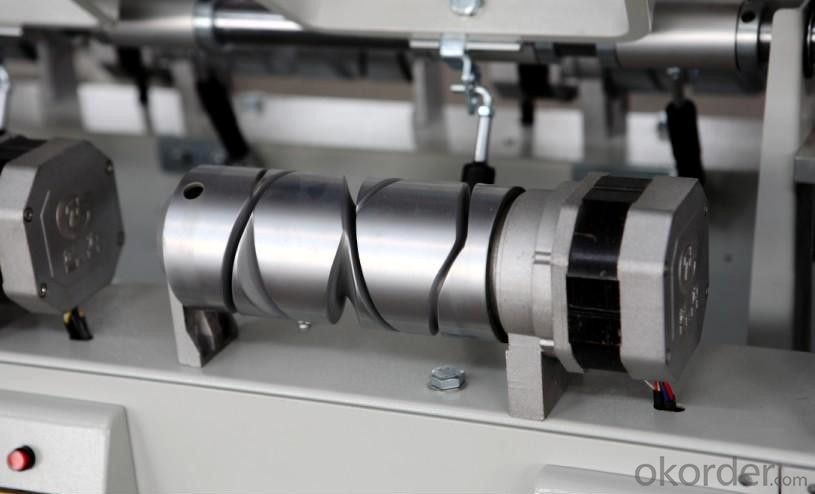

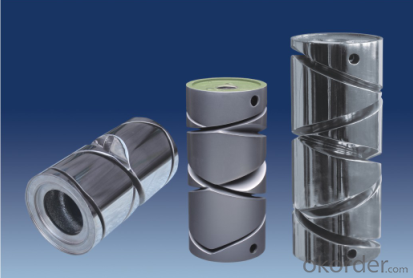

Cnc Machining Turning Aluminium drum of Winding Machine Parts

Adavantages:

Cnc Machining Turning Aluminium drum of Winding Machine Parts has the following advantages:

Best groove curve, ultra-fine processing, and high smooth finish(Ra<0.2μm).

Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

High wear resistance, corrosion resistance.

Coating has high density,small crystallization , low porosity.

Product Description:

Pictures shows of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Models of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Model | Groove number of turns | Lead | Aperture | Outer diameter | Length | Package angle |

CT-B | 2.5 | 154 | φ20 | φ82 | 176 | 0° |

CT-S | 2.5 | 147 | φ20 | φ82 | 183 | 0° |

CT-S1 | 2 | 150 | φ20 | φ95 | 176 | 0°—3°30′ |

CT-J | 2.5 | 152 | φ20 | φ82 | 176 | 3°30′—5°57′ |

Ps: CT-grooved drum, B-used in assembly winder, S-slack winding, J-conical cylinder, Z-gooved drum of atomatic winder, L-roller, M-friction drum

Packaging & Delivery of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

Packaging Detail: Wooden case or as per customers' requirements

Delivery Detail: 5 days from receiving the advance payment

FAQ of Cnc Machining Turning Aluminium drum of Winding Machine Parts:

· Q:What is the machine used for?

A:Cnc Machining Turning Aluminium drum of Winding Machine Parts is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 100 pc.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is spinning down?

- The emergence of spinning has not only changed the original society of textile production, the development of later spinning tool is very far-reaching, and it as a simple spinning tool, has been used for thousands of years

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The earliest use of hydraulic spinning machine is horsepower driven, and later cited hydraulic. The use of hydraulically operated machines is of great importance in the history of the textile industry, where textile workers can operate the machine at hand, but once the power is used, the worker can not leave the power source, As the beginning of the factory system. The first batch of factories in history was established to make textiles. In 1779, S. Crompton, in conjunction with the advantages of the Jenny spinning machine and the hydro spinning machine, developed a spinning mule that spun out fine and strong spun yarns,

- Q: What is the difference between yarn spinning and ring spinning?

- Such as carding, combing and blending, the bead is driven by the bobbin through the yarn to rotate around the collar, twist, and the friction of the collar is slightly smaller than that of the bobbin and the winding speed is high, The shape of the ring yarn, the fiber is mostly inside and outside the transfer of the conical spiral, so that the fiber in the yarn inside and outside the winding connection, the yarn structure is close, high strength, suitable for the system and weaving and knitting and other products.

- Q: Textile equipment to protect the work is not a special type of work?

- , In accordance with the current social insurance policy, special types of early retirement must also have four conditions: First, engaged in special types of work must be the former Ministry of Labor and the central authorities approved the special types of work, different industries between the special types of work Can not match each other. Second, must be in the original state-owned, collective enterprises engaged in high-altitude and particularly heavy manual labor accumulated over 10 years; engaged in underground, high temperature work accumulated over 9 years; engaged in other toxic and harmful work accumulated over 8 years. Third, the staff file on its special trades experience in the original record. Four men over 55 years of age, women over 45 years of age, and the cumulative payment of 15 years of years.

- Q: How is the machine automatically connected to the machine?

- At the same time using tube knot method, yarn tail length of about 20mm.

- Q: What is the cashmere dyeing process?

- The raw material cost is mainly composed of two parts: raw material cost and processing cost. In order to reduce the product cost, the raw material is the first choice.

- Q: What is the textile process?

- Spinning process mainly include: cotton, carding, combing, and bars, roving, spun yarn.

- Q: What are the mechanical characteristics of textile machinery?

- The complete set of textile machinery is also subordinate to the process. For example, according to the cotton spinning process configuration of complete sets of machines, models arranged in order, the number of fixed relationship between the number of machines are determined by the process requirements. Another example is the scope of the work of the weaving machine weaving products, the need to configure the appropriate range of work inspection cloth, the amount of cloth and dyeing and finishing equipment, also belong to the set of. Therefore, the complete set of textile machinery not only exists in a factory, also exists between the plant and the plant.

- Q: Textile machinery production process is probably what kind of?

- Carding parts of a wide variety of materials, many shapes, but generally is the first processing parts, according to the requirements of the drawings, in addition to the requirements of the part of the preparations are nothing more than casting and forging, welding pliers and so on.

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Technology: Accumulation of workshop handicraft technology;

Send your message to us

Cnc Machining Turning Aluminium drum of Winding Machine Parts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 12000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords