Soft Cone Yarn Winding Machine for Wing Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Soft Cone Yarn Winding Machine:

Soft Cone Yarn Winding Machine is used for winding yarns on cones.

Application:

Soft Cone Yarn Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

Main Features:

Soft Cone Yarn Winding Machine has the following advantages:

· High precision, highly polished, self-lubricating on surface, litter friction with yarn are our basic functions.

· Highly accurate, mass-radius product is less than 10g·mm, and the linear velocity can reach 2000m/s.

· High-tech in dealing with surface, and it makes our grooved drums have high wear resistance, corrosion resistance and makes sure the hardness of the groove and surface are the same.

Good forming and uniform linear density.

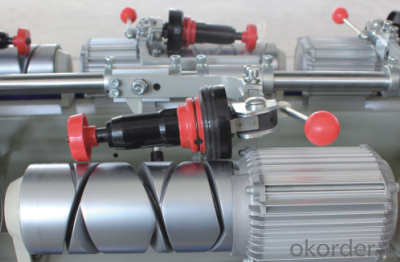

Images of Soft Cone Yarn Winding Machine:

Specification:

| Items | Technical parameters |

| Types of winding | Drum,Random |

| Mechanical speed | Up to 1200m/min (process speed depending on quality of yarn and feed packages) |

| Package shape and feed packages) | Cylindrical or conical packages |

| Traverse length | 147mm,150mm,154mm |

| External dimensions | 13410mm(length) ×700mm(width) ×1680mm(height) |

FAQ of Soft Cone Yarn Winding Machine:

· Q:What is the machine used for?

A:Soft Cone Yarn Winding Machine is suitable for processing PP, PE split film yarn/ just twine, cotton twine, weaved twine to ball.

· Q: What is the MOQ?

A: 1 set.

· Q: What is the lead time of the product?

A: 5-20 days after payment

- Q: What is the second-hand textile machinery import clearance process?

- 3. In addition, there is inventory backlog of equipment, although it has exceeded the manufacturer's warranty period or a significant loss of parts, but still maintain the original technical performance, play the original role of the equipment has also been identified as second-hand equipment.

- Q: How does the mechanical wave generated in the spinning process work?

- Mechanical waves meet, you can cross each other, do not interfere with each other

- Q: What are the high efficiency of the spinning machine and the Jenny spinning machine of the invention?

- The emergence of the multi-spindle spinning car, the development of handmade textile machinery to the peak, the manual spinning industry, the multi-spindle spinning machine is to enhance the efficiency of the most complete, the fastest spinning wheel. 5. Spinning mechanization Until the emergence of the industrial revolution, the rapid growth of the market, the demand for production increased after the emergence of new spinning technology.

- Q: What is a large hydraulic spinning wheel?

- Song and Yuan Dynasties, with the socio-economic development, in a variety of transmission machine on the basis of spinning, and gradually produced a dozens of spindle spindle

- Q: What are the risks of safety accidents in the textile machinery industry?

- The Fourth, in the exposed parts of the drive did not take security measures.

- Q: Who invented Jenny spinning machine?

- In the mid-18th century, British goods were increasingly sold overseas, and the production of handmade workshops was inadequate. In order to increase production, people find ways to improve production technology. In the cotton textile sector, people first invented a shuttle called the weaving tool, greatly accelerated the speed of the weaving, but also to stimulate the demand for cotton yarn. In the 1860s, the weaver Hagreaves invented the "jenny machine" hand spinning machine. "Jenny machine" can be spinning a lot of cotton thread, greatly improving the productivity.

- Q: Is the textile machine made of those accessories?

- The mechanical part of the loom, including the opening, weft insertion, beating, winding, sent by the five major sports institutions, a lot of auxiliary parts, especially the modern loom, mechanical and electrical integration, a high degree of automation

- Q: What is a pedal loom?

- To the Qin and Han Dynasties, the Yellow River Basin and the vast areas of the Yangtze River Basin has been widely used.

- Q: Textile machinery production process is probably what kind of?

- All kinds of machinery in terms of the principle to the structure has a very big difference.

- Q: What is the historical background of the mechanization of the British cotton textile industry?

- Market: Britain's overseas colonial activities have expanded the overseas colonial market, enclosure movement has expanded the domestic market;

Send your message to us

Soft Cone Yarn Winding Machine for Wing Yarn

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords