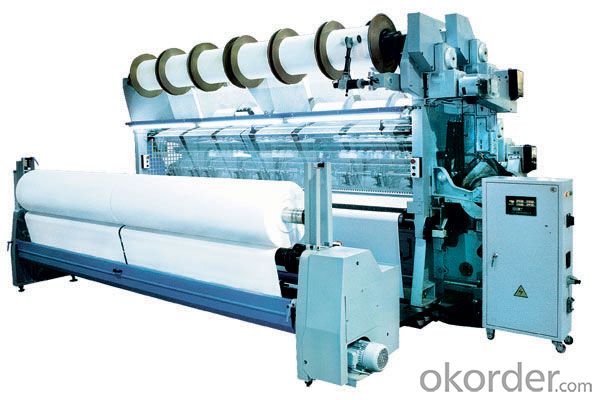

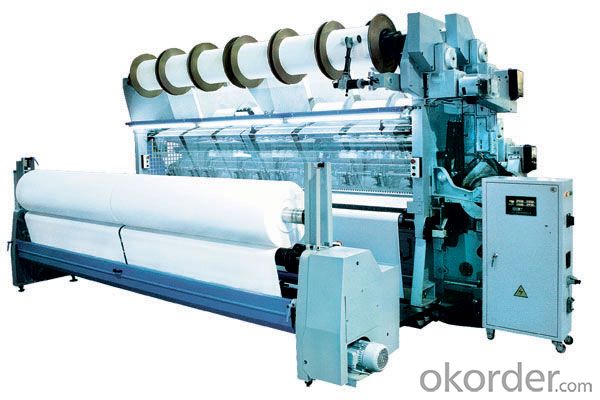

TERRY WARP KNITTING MACHINE GE272 SERIES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Usingpolyamide fibre,polyester filament fibre,cotton yarn and fine fibre forknitting one-sided terry fabric.

Application:

Using polyamide fibre,polyester filament fibre,cotton yarnand fine fibre for knitting one-sided terry fabric and double-sided terryfabric such as towel,bath towel,bathrobe,towel quilt,dish toweletc。In case of shearing and raising the long loop,it can also bemade into cotton blanket etc.Due to being fasted With the

stitch of base cloth,the terry is flat and smooth,and hardlycomes out of base cloth.

Technical date sheet

MAIN TECHNICAL SPECIFICATIONS: | ||

Model | GE272SM | GE272SP |

Needle | Compound needle | |

Working Width | 3454mm(136”) 5255mm(186”) | |

Gauge | E24,E26,E28 | |

Knitting Speed(MAX.) | 750rpm(136”) 750rpm(136”) 1300rpm(186”) 1300rpm(186”Chemical fibre) | |

Height of Terry | L1:4mm(MAX.) L4:6mm(MAX.) | 2mm or 3mm |

Number of Guide Bars | 4 guide bars(2 ground bars,2 terry bars) | 3 guide bars &1sinker bar |

Characteristics | The shog are under control of 6 tracks of pattern wheel.Fixed with a conversion device between terry loop and plain stitch. | 。 With an additional device,it can knit double terry fabric. |

Density Range | 6.18~70.4courses/cm | |

Power | (Main motor):5.5KW(136”); 9KW(186”) (Inching motor):0.75KW (Batching motor):1.5KW | |

Beams | φ535mmX535mm(φ21”X21”) orφ762mm X535mm(φ30”X21”) | |

Weight(Kg) | 8000 | |

- Q: What is spinning down?

- According to archaeological data, in the whole of China dozens of provinces and cities have been excavated in the early residents of the site, almost all the major parts of the spinning spindles unearthed

- Q: How does the mechanical wave generated in the spinning process work?

- Mechanical waves meet, you can cross each other, do not interfere with each other

- Q: Textile machinery industry how to have prospects?

- Prospective Industry Research Institute Textile Machinery Manufacturing Industry Research Group, said the world's leading textile machinery enterprises in China have invested and set up factories in China, the scale of production in China has reached the Chinese textile machinery production 1/3.

- Q: What is the difference between yarn spinning and ring spinning?

- Ring spinning is the largest and most versatile spinning method on the market, and the strip or roving is introduced by the rotation of the ring strand through the ring strand, the bobbin winding speed is faster than the wire ring, and the cotton yarn is twisted It is widely used in all kinds of short fiber spinning engineering.

- Q: What are the different effects of textile equipment?

- , Low technology content, the process of redundant, such as cotton, to experience spinning, weaving

- Q: Is there a textile industry in the Qin Dynasty?

- Ancient Chinese textile and printing and dyeing technology has a very long history, as early as in the primitive society, the ancients in order to adapt to climate change, has learned to take the land, the use of natural resources as textile and printing and dyeing raw materials, and the manufacture of simple textile tools.

- Q: What are the risks of safety accidents in the textile machinery industry?

- Fifth, the machine did not do regular inspection and maintenance. These are the risk of security incidents.

- Q: Is the textile machine made of those accessories?

- There is no concept of spinning machine, spinning and weaving are separate, and spinning and weaving process is very long, do not want you to imagine only one or two equipment can be, the entire production process involved in the equipment up to a dozen

- Q: What modern textile machinery?

- One is to make the whole machine. The other is the manufacture of special spare parts (such as spindle, cradle, steel collar, bead ring, knitting needle, needle cloth, heddle, stop sheet, etc.).

- Q: Textile machinery production process is probably what kind of?

- Textile machinery is a very broad concept, including a lot of machinery, a carding machinery, spinning machinery, weaving machinery and so on.

Send your message to us

TERRY WARP KNITTING MACHINE GE272 SERIES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords