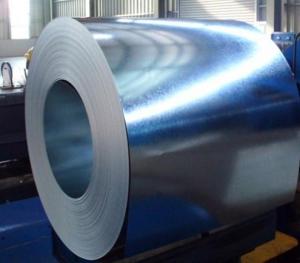

SLIT HOT ROLLED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Production | hot rolled steel coils |

Port | Tianjin, China |

Category | Minerals & metallurgy |

Thickness | 1.8-16mm |

Width | 0-600mm |

Coil Weight | about 23 tons |

Material Grade | SS400\Q235\Q345B |

Technique | hot rolled |

Standard | GB ,JIS |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Surface | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled |

Package | in bundles, strapped by strips. Or as customer’s requirement |

Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

MOQ | 10 tons |

Payment | 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation |

Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

Certificate | ISO |

- Q: A song by brokencyde is called Blue Steel.... a verse in it says Don't make me show you blue steel.

- Reference is to a gun which is typically the process of Bluing the steel of the guns metal parts.

- Q: Can steel coils be painted?

- Yes, steel coils can be painted. Painting steel coils not only enhances their aesthetic appearance but also provides a protective coating against corrosion and other environmental factors. The coils are typically pre-treated and primed before the application of paint to ensure proper adhesion and durability.

- Q: How do steel coils contribute to the HVACR equipment industry?

- Efficient heat transfer and effective functioning of HVACR systems are crucial roles played by steel coils in the HVACR equipment industry. These coils, made of high-quality steel, are integral components of air conditioners, heat pumps, refrigerators, and boilers. Facilitating heat transfer is one of the primary functions of steel coils in HVACR equipment. Designed to efficiently transfer heat between the refrigerant and the surrounding air or water, these coils utilize a large surface area and good thermal conductivity. As a result, HVACR equipment can effectively cool or heat a given space, ensuring optimal energy efficiency and reducing operating costs in residential and commercial applications. In addition to heat transfer, steel coils contribute to the overall durability and longevity of HVACR equipment. The use of corrosion-resistant steel in these coils helps prevent damage from moisture and other environmental factors. This reliability is particularly important as HVACR systems often face harsh conditions and must operate continuously to maintain comfortable indoor environments. Furthermore, steel coils offer versatility and customization options to meet specific HVACR requirements. Manufacturers can vary the size, shape, and configuration of the coils to fit available space and optimize performance. This flexibility enables efficient integration of steel coils into different HVACR equipment, ensuring they meet the specific heating and cooling needs of diverse environments. In conclusion, steel coils are indispensable in the HVACR equipment industry. They enable efficient heat transfer, enhance durability, and offer customization options, ensuring effective functioning and energy efficiency of HVACR systems. Manufacturers can provide reliable and long-lasting solutions for heating, ventilation, air conditioning, and refrigeration needs in residential and commercial settings by incorporating high-quality steel coils into their products.

- Q: What are the different methods of embossing steel coils?

- There are numerous techniques for embossing steel coils, each possessing unique characteristics and applications. Some of the most prevalent techniques include: 1. Hot embossing: By heating the steel coil to a high temperature and pressing it between two engraved rollers, this method allows for intricate designs or textures to be imprinted onto the surface. The heat softens the steel, facilitating the desired pattern transfer. 2. Cold embossing: In contrast to hot embossing, cold embossing does not require heating the steel coil. Instead, it employs pressure and specifically designed dies or stamps to produce the desired pattern. Cold embossing is commonly used for simpler designs or when working with heat-sensitive materials. 3. Roller embossing: This technique involves using a series of rollers with engraved patterns to imprint the design onto the steel coil. The coil is passed through the rollers, and the applied pressure transfers the pattern onto the surface. Roller embossing is often utilized for larger-scale production, delivering consistent and uniform results. 4. Laser embossing: A modern method that employs laser technology to create patterns on steel coils. The laser beam selectively melts or vaporizes the metal, generating the desired design. Laser embossing offers high precision and flexibility, making it suitable for intricate and detailed patterns. 5. Press embossing: This technique utilizes a press machine equipped with custom-made dies to imprint the desired pattern onto the steel coil. The coil is positioned between the dies, and the press machine applies pressure, transferring the pattern onto the surface. Press embossing is commonly used for large-scale production, achieving high-speed and high-volume embossing. Ultimately, the choice of embossing method depends on various factors, including design complexity, production volume, material properties, and cost considerations. Each technique possesses advantages and limitations, necessitating careful selection by manufacturers based on their specific requirements.

- Q: I got a muzzy carp point arrow and its head is steel with 1.7% carbon, its used in the water. Will i have to dry it after every use or is it stainless. Thanks

- stainless steel also rusts it just takes longer to. what you have is just a higher grade of steel, which isn't stainless anyways so yeah wipe it clean when you're done.

- Q: How are steel coils used in the manufacturing of steering columns?

- Steel coils are used in the manufacturing of steering columns as they provide the necessary strength and flexibility to withstand the forces and vibrations experienced during steering. The coils are shaped and formed into the desired design, allowing for the smooth and controlled movement of the steering column.

- Q: What are the different methods of levelling steel coils?

- Different methods are employed to level steel coils, depending on their specific requirements and applications. Some commonly used methods include: 1. Roller Leveling: This method utilizes a series of rollers to apply pressure on the steel coil, effectively reducing residual stresses and eliminating any waviness or curvature. It is commonly used for achieving high flatness in thinner gauge coils. 2. Stretch Leveling: In this method, the steel coil is stretched beyond its yield point to eliminate shape defects. The coil is subjected to tension in a stretcher leveler machine, which elongates the material and removes inherent stresses. It is often used for achieving greater flatness in thicker gauge coils. 3. Temper Milling: This method involves passing the steel coil through a temper mill equipped with work rolls on top and bottom. The temper mill applies tension to the coil, flattening it and improving its shape and surface quality. It is typically used for higher strength steel grades. 4. Corrective Leveling: When the steel coil exhibits significant shape defects like wavy edges or center buckles, corrective leveling is employed. This method selectively removes material from specific areas of the coil to achieve a flat and uniform surface. Laser or plasma cutting machines are often used for this process. 5. Tension Leveling: Similar to stretch leveling, tension leveling applies tension to the coil without exceeding its yield point. Bridle rolls are used to stretch the material, eliminating internal stresses and leveling the coil. It is commonly used for achieving flatness in higher strength and thinner gauge coils. These methods can be used individually or in combination, depending on the specific requirements and desired end product. Each method has its advantages and limitations, and the choice of leveling method depends on factors such as coil thickness, material properties, and desired flatness.

- Q: How are steel coils protected against corrosion?

- Steel coils are protected against corrosion through various methods such as applying protective coatings like zinc, aluminum, or polymer, or using a process called galvanization where the coils are coated with a layer of zinc. Additionally, storing the coils in a controlled environment with low humidity and proper ventilation also helps prevent corrosion.

- Q: What are the key properties of steel coils?

- Some key properties of steel coils include high strength, durability, and flexibility. They have excellent resistance to corrosion, making them suitable for various applications in construction, automotive, and manufacturing industries. Steel coils also offer good formability and can be easily shaped into different sizes and dimensions. Additionally, they have high thermal conductivity, allowing for efficient heat transfer in certain applications.

Send your message to us

SLIT HOT ROLLED STEEL COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords