Magnesite Chrome Brick Slag Control System with Slide Gate CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

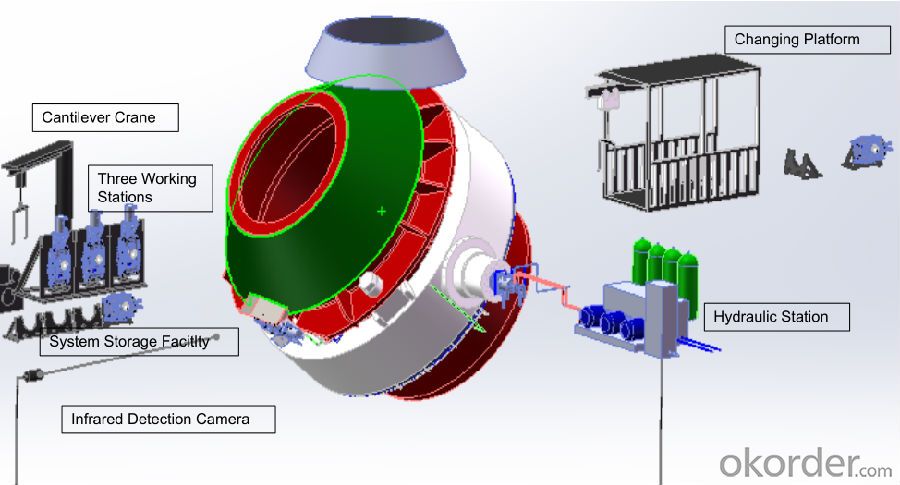

Slag control system with slide gate

Production Base

◆ 17 Refractory plants locate in 9 different cities

◆ All the plants are ISO 9001:2008 certificated

◆ 15 professor level senior engineers: 239 engineers,5 senior experts committed Iron & Steel industry.

Production Capacity

◆ Refractory Brick:300,000 tons

◆ Monolithic Refractories:200,000 tons

◆ Precast Refractories:30,000 tons

◆ Functional Refractories:30,000 tons

Production Facilities

◆ Raw Material Storage System

◆ Tunnel Kiln

◆ Automatic Batching System

◆ Automatic Control System

◆ EIRICH Mixer Machines

◆ LAEIS Pressers

Slag Control System

The slag control system contains:

◆ Fixed Parts(Upper Slide Gate and Nozzle)

◆ Switch Parts(Sliding System with LowerSlide Gate and Nozzle inside)

◆ Spring System

Technical Advantages

◆ Control Slag Output and rephosphorization, improve the steel purity

◆ Lower the slag content in ladle and keep the thickness of slag

◆ Save desoxidant agent and alloy consumption

◆ Increase the life for linning and taphole

◆ Creat better working situation for worker

- Q: What are the differences between magnesium chrome bricks, such as direct bonding, re bonding, semi bonding, CO sintering and chemical bonding? Hope expert advice..

- Direct bonded magnesia chrome brickThe loose effect caused by the expansion of spinel when the oxide of magnesia brick is directly reacted with the oxide of iron can also be used to make magnesia chromite brick with synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: Process for producing magnesia chrome brick

- The oxide of iron reacts to produce a loose effect caused by the expansion of the spinel. Also, the magnesia chrome brick can be made from the synthetic common sintered material. In addition, there are non burned magnesia chrome bricks, for example, non burned magnesia chrome bricks combined with inorganic magnesium salt solutions. The unfired magnesia chrome brick has the advantages of simple production process, low cost and good thermal stability, but the strength of the high temperature is far less than that of the burnt brick. In the late 50s, a so-called "direct bonding" magnesia chrome brick was developed. The characteristics of this brick raw material is pure, high firing temperature, periclase and spinel phase with high temperature directly, silicate and other low melting point phase for island distribution, therefore, significantly improve the high temperature strength and slag resistance of brick.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- I produce clay bricks, and my bricks stand at 1500-1700 degrees. Specific depends on what kiln, brick is only part of it

- Q: Magnesia chrome brick

- Magnesia chrome brick to Magnesium Oxide (MgO) and chromium oxide (Cr2O3) as the main ingredient, refractory periclase and spinel as main mineral components of products. The bricks have high refractoriness, high temperature strength, strong resistance to alkaline slag, good thermal stability, and certain adaptability to acid slag. The main raw materials for making magnesia chrome bricks are sintered magnesia and chromite. The purity of magnesia raw materials should be as high as possible, chrome iron ore chemical composition requirements: Cr2O3:30 - 45%, CaO = 1 ~ 1.5%.

- Q: Magnesium chrome brick price?

- Magnesia brick factory with strong technology foundation as the basis, has developed more than 40 varieties of products, including building materials, non-ferrous metals, iron and steel and other fields, won the national high-tech products nearly a dozen, four patents, including magnesia spinel brick reached the world advanced levelFrom July 2006 to now won the high-tech enterprises in Liaoning province; National Standardization Management Committee issued the "adopting international standard product certificate" enterprises; in 2009 passed the ISO9001 quality management system certification; the famous brand products of Liaoning Province certificate certificate and certificate management, the reliable guarantee for the quality of products.

- Q: What are the types of magnesia chrome bricks for industrial use?

- It is possible to judge by the concrete kiln. The magnesium chrome bricks produced by real gold company are very good. Our factory purchased them the year before last, and their technicians were very professional, and gave us very good suggestions.

- Q: What is a half combination of magnesia chrome bricks?

- Semi - combined magnesia chrome brick is a kind of refractory product made from partly fused magnesia chromite sand.

- Q: With different capacitance magnesia brick brick

- Burnt magnesia brick is made of high quality sintered magnesia as main raw materials, paper pulp as binder. After mixing and high pressure molding, it is fired in a high temperature tunnel kiln over 1550 degrees celsius. It has good thermal stability, corrosion resistance and spalling resistance. Widely used in converter, arc furnace and other industrial furnace lining refractory.

- Q: What is the difference between magnesia chrome brick and direct bonded magnesia chrome brick?

- The magnesium chromium brick with the direct bonded magnesia chrome brick is different: 1 with the purity of magnesia (raw materials) 2: the sintering temperature of common magnesia chrome brick sintering temperature at 1550 DEG ~1600 DEG, direct the magnesium chromium brick sintering temperature is over 1700 DEG C, because of its more than 1700 DEG C, magnesia chrome brick microstructure occurred change, and periclase chromium ore directly combined, so called direct bonded magnesia chrome brick

- Q: What are the main raw materials of magnesia chrome bricks?

- Magnesium alloys are alloys based on magnesium and other elements. Its characteristics are: small density (1.8g/cm3 magnesium alloy or so), high specific strength, high modulus of elasticity, good heat dissipation, good shock resistance, greater impact load capacity than aluminum alloy, good resistance to organic and alkaline corrosion. The main alloying elements are aluminum, zinc, manganese, cerium, thorium, and a small amount of zirconium or cadmium.

Send your message to us

Magnesite Chrome Brick Slag Control System with Slide Gate CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords