Single Stage Rotary Vane Vacuum Pumps with Oil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Stage Rotary Vane Vacuum Pumps

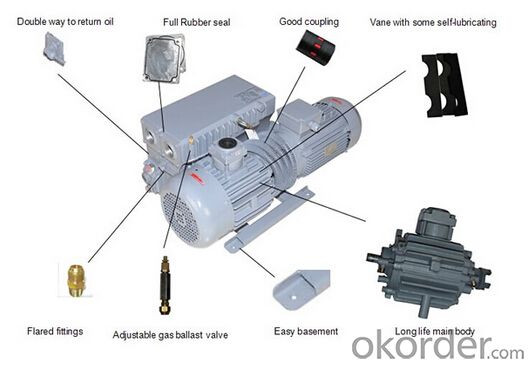

1.Structure of Single Stage Rotary Vane Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Single Stage Rotary Vane Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

3.Single Stage Rotary Vane Vacuum Pump Images

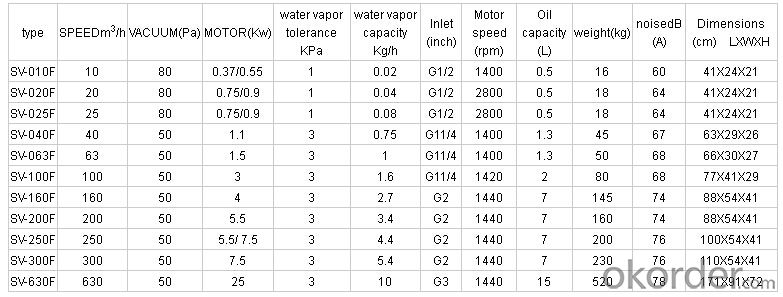

4.Single Stage Rotaty Vane Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: What is a water pump coupling device?

- The automatic coupling device of the water pump coupling device has compact structure and small occupation area. The sump pump works because it is submergedThe utility model can be directly installed in a sewage pool, and no special pump house is needed to install a pump and a machine, thereby saving large amounts of land and infrastructure expenses

- Q: Rotary vacuum pump does not meet the requirements of vacuum, what are the reasons?

- (1) the disk, stator or bushing is worn and shall be inspected, trimmed or replaced with a rotary vane vacuum pump.(2) the pump temperature is too high, which not only reduces the viscosity of the oil, increases the saturated vapor pressure, but also may cause cracking of the pump oil. Ventilation, cooling and environmental temperature should be improved. If the exhaust gas temperature is too high, should be cooled before entering the pump, the environment temperature is high, should try to use a better high speed vacuum pump oil or 3# diffusion pump oil. (10) because of the deformation, wear or movement of the parts, the maximum opening height of the check head can be reduced or even unable to be opened, the intake of oil is too little, and the vacuum degree of the rotary vane vacuum pump is reduced, and should be adjusted as shown in the assembly section. Open high, more oil, but open too high, check valve in some places on the stop, it will not automatically drop, lost to prevent oil returns. The commonly used rotary vane vacuum pumps mainly include double stage rotary vane vacuum pump and single-stage rotary vane vacuum pump

- Q: What is the name of the day pump and ground pump? Specific introduction

- Day pumpDay pump is called "day pump", the main reason is that it can deliver concrete to a certain height, make up for other concrete pump transportation shortage. Compared with other concrete pumps, the pump has its own boom, and the concrete can be transported without the use of artificial cloth. It is very convenient for use. At present, China's longest boom pump is 101 meters, which means that 101 meters under the floor can be completed with the help of day pump concrete delivery. In addition, the pump is equipped with a chassis, so compared with the ground pump, it can walk independently, moving very convenient, you can quickly move from one site to another location.

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- If the fish tank is made of metal, the fish tank is grounded or connected to the zero line, and then the fire line is put into the water, then your fish will be electrocuted immediately. Go back to the submersible pump, submersible pump line and the zero line very close, even if the firing line and the zero line at the same time the leakage occurs, fish could not swim between the firing line and the zero line, so the tank submersible pump leakage will cause the following hazards: 1, electric shock. 2, submersible pump short circuit. 3, the submersible pump serious fever, resulting in water temperature tank.

- Q: The difference between submersible pumps and centrifugal pumpsWhat's the difference between the two? What is applicable and what?

- Difference:The installation position is different: one can discharge water, one is on the ground.The work principle is different: the principle of submersible pump is similar to the electric fan, centrifugal pump through centrifugal force to make the water throw out. According to the principle of centrifugal force design,

- Q: What is the pumping property of concrete?

- Pumpable concrete slump is generally greater than 160mm, the mortar content is too low, the maximum aggregate size of not more than 1/3 of the diameter of the pump pipe, sending process segregation, plugging in the pump.

- Q: Is vane pump good or gear pump good?

- 1) the reversible design of gear pumps can also usually reverse, but reverse after the suction port change, and the pump safety valve does not work; leaf pump is generally not allowed to reverse. 3) the single acting vane pump can be designed to change the eccentric distance by moving the stator at the constant speed, so as to achieve the purpose of variable direction.

- Q: Centrifugal pump flow, why can be adjusted through the outlet valve? Can the flow of the reciprocating pump be adjusted in the same way?. Why

- Reciprocating pump is a positive displacement pump, the volume change of flow is the unit of time, constant flow speed constant, can not rely on increased resistance to change the flow resistance increase is only leaked, only small changes in flow.

- Q: How accurate is the metering pump?

- The measuring accuracy of the stable metering pump is as follows:In a diaphragm metering pump, the reciprocating motion of the plunger is passed to the diaphragm through the hydraulic chamber between the plunger and the diaphragm. In order to maintain the normal movement of the diaphragm, the hydraulic chamber is required to keep the volume of the liquid in the space (usually using hydraulic oil) unchanged. In order to ensure that the volume of the formation of membrane movement is always equal to the stroke volume of the plunger pump, so as to maintain the stability of the flow, but in the actual operation of the pump, the plunger seal will inevitably cause leakage at the same time, there may be a gas into the hydraulic chamber

- Q: Do you have a suction pump higher than 9 meters?

- This screw self-priming pump suction process can be more than ten meters or more, my family is using this

Send your message to us

Single Stage Rotary Vane Vacuum Pumps with Oil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords