Single Component Polyurethane Coating All Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single Component Polyurethane Waterproof Coating Introduction

Single-component moisture-curing pure polyurethane waterproof coating is a kind of liquid polymer waterproof material,

suitable for dry and wet base surface construction, solidified into tough and elastic, non-toxic and tasteless waterproof

film after coating. It is a new type of environmental friendly waterproof material without solvent.

Single Component Polyurethane Waterproof Coating Application

•Building roof

•Concrete

•Wall

•Water Tank Structure

•Floor(kitchen floor, bathroom floor ect)

•Underground Tunnel

•Sewerage Structure

•Movement Joint

•Wet Area, Pipes, Sewer & etc.

Single Component Polyurethane Waterproof Coating Advantage

1.water based and solvent based

2.Solid content above 80%

3.Durable performance, UV resistant, ageing-resistant,resistant high and low temperature,antifatigue, withstand constant immersion in water

4.Good splicing performance

5.Operate conveniently, low viscosity

6.Can splicing with concrete and many kinds board stuff

7.Will not change color after used

8.Apply for Roof,Swimming Pool,Tank and more

Single Component Polyurethane Waterproof Coating Specifications

NO. | Items | Ⅰ | Ⅱ |

1 | Tensile Strength MPa≥ | 1.9 | 2.45 |

2 | Elongation at Break %≥ | 550 | 450 |

3 | Tearing Strength N/mm≥ | 12 | 14 |

4 | Bend at Low Temperature°C≤ | -40 | |

5 | Unpermeability0.3MPa 30min | Impermeable | |

6 | Solids Content%≥ | 80 | |

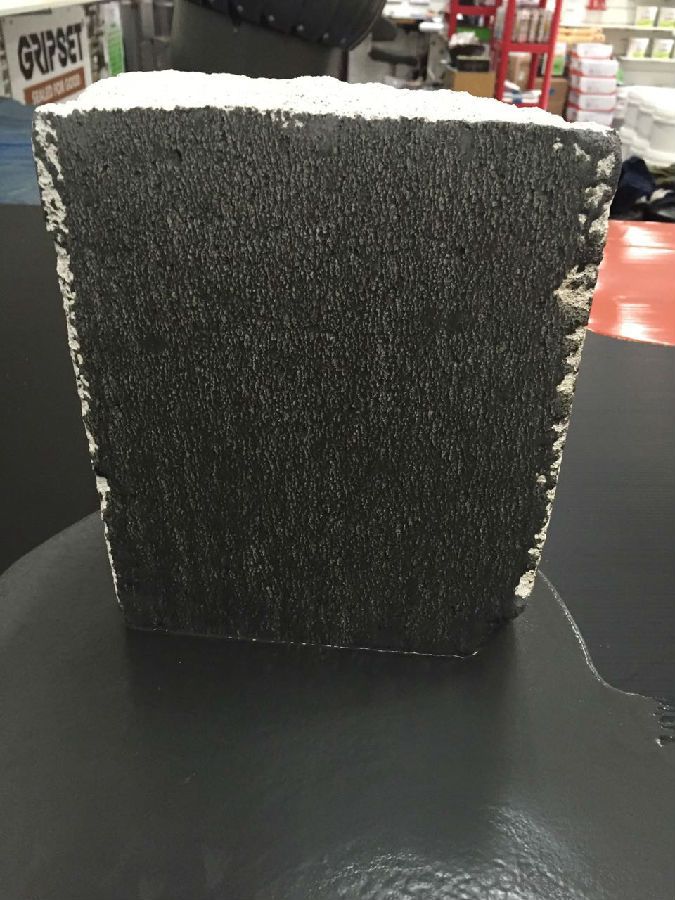

Single Component Polyurethane Waterproof Coating photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q: Bathroom first leveling or do waterproof, what is the difference

- Is the first water and then leveling. Home improvement toilet ground specific process practice: 1. The base layer, and which layer with the structural board, with cement mortar wipe. It is recommended to set the floor drain, the grassroots level should be flat and the direction of the leak to the slope. Against the wall and the root of the root should be wiped rounded.

- Q: Eastern rainbow waterproof how to do

- Do not know where you use, waterproof as if a lot of materials. I know there are coiled, painted.

- Q: How to ensure the waterproof quality of the underground shear wall (retaining wall)?

- 1, when the basement buried depth is not large, you can use the digging method, once in place, and then press the first on the next, the order of construction.

- Q: What decoration materials, light and water, and the wall, the perfect combination of glass

- Five, scraping gum The excess residue of the material to be scratched, scraping plastic tool angle consistent, at one go, scraping gum immediately after the completion of tearing tape or grain pattern paper. Remove the excess glass compound, if stains, can be removed with a damp cloth. Six, finished product protection Do not touch within 24 hours, do not press within 48 hours.

- Q: Find the construction steps for waterproof coatings

- 3, note (1) rain weather and five wind above the weather shall not be construction. (2) coating waterproof layer shall not have bottom leakage, cracking, holes and other defects and peeling, bubbling, carcassing and wrinkle phenomenon. Coating waterproof layer and the base should be bonded between the solid, no hollowing, trachoma, delamination and so on. (3) the coating site should be continuous, solid, shall not appear Alice, hollowing parts. (4) rigid protective layer before the completion of any personnel shall not enter the construction site, so as not to damage the waterproof layer; coating of the overlapping parts should be care by the staff. (5) roof should be used lime soil, clay or sub-clay for backfill, thickness 50 cm, backfill shall not contain stones, gravel, ash and organic matter. Artificial compaction of each layer 25 cm, mechanical compaction of each layer 30 cm, rammed to prevent damage to the waterproof layer. In the backfill thickness of more than 50 cm, it is allowed to use mechanical backfill rolling.

- Q: Home improvement waterproofing problem

- 5, the kitchen is designed to be waterproof. In principle, there should be water and water treatment should be done to avoid the water pipe out of the problem, affecting the destruction of downstairs decorating

- Q: What material waterproofing can be mixed with cement sand

- Waterproof layer used in the cement label of not less than 32.5MPa, the thickness of cement mortar should be 2-3cm, the surface clean and solid without cracks; mortar leveling layer of cement should not be less than 32.5MPa, leveling layer to smooth compaction, finished product maintenance is not low In 5 days.

- Q: Can Henkel have water against him?

- Can ah ~ watered effect on the discount friends are high with the general are good, powder + pulp! Do not need to add water

- Q: Roof leakage, what materials do the best waterproof

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. The first is to see if there is no cracks in the roof, the original waterproof layer is not aging, the roof of the original SBS waterproofing membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking. There is a block on the roof of the gutter is not blocked in the countryside, there are still a large number of tile-roofed house, when the tiles due to damage caused by the roof leakage, as long as the replacement of tiles can be, this step is also known as "

- Q: What are the materials used in the ceiling?

- Kitchen bathroom ceiling material 2: aluminum plate material ????Aluminum buckle board is based on aluminum alloy as the main substrate, through the process to get the finished product, and now the aluminum plate in the use of integrated ceiling in the larger. In the home improvement specifications are generally 300MM * 300MM, 300 * 450mm, 300 * 600mm and other different sizes, because of its excellent board layer, with noise, heat insulation, light weight characteristics, while its color is also more Kind of choice, to meet the different needs of consumers.

Send your message to us

Single Component Polyurethane Coating All Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords