Silica Brick Reinforced Aluminium Silicate Fire Bricks for Copper Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Silicate bricks for hot stoves feature sharp dimension,low expansion,little residual quartz, low true density.low creep rate,good thermal shock resistance upon 600°C and high refractoriness under load, It mainly used at high temperature area include arch and upside of hot stove and upside of checker. Andalusite bricks are mainly used in the cooling wall of blast furnace, chemical and ceramic industry, the door of coke oven, or as the lining and checker of hot blast furnaces.

Application:

1 Building materials for blast furnace

2 Building materials for hot-blast stove

3 Building materials for coke oven

4 Building materials for steel making furnace

Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Abundant Experience. Prevent cracks and twist in bricks.

3.Different Moulds. Save mould fees for you.

4.Strict Quality Control. Meet clients' quality requirement.

Typical features:

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

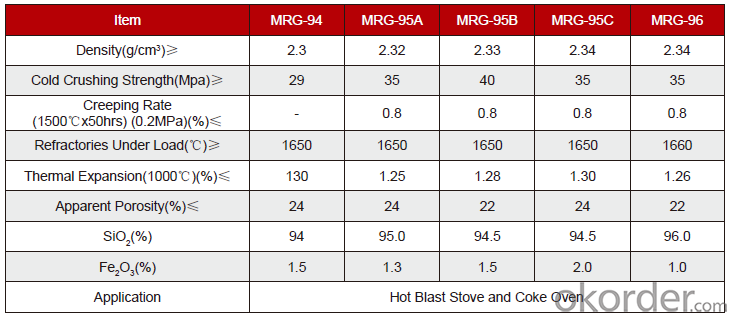

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

- Q: The introduction of silica brick

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature.

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: Such purpose and scope please give me detailed points thank you because I am learning stage

- Acidic silica brick refractory material, has good acid resistance and slag erosion, softening temperature is as high as 1640 to 1670 DEG C, in the long-term use volume is relatively stable under high temperature. The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass. Tridymite and cristobalite and quartz remaining at low temperature due to phase change, volume changes greatly, so the brick thermal stability at low temperature is very poor. In use, under 800 degrees Celsius, slowly heating and cooling, so as not to produce cracks. The use of temperature in blast furnace so should not be below 800 DEG on. The properties and process of silica crystal with SiO2 transformation is closely related, therefore, the proportion of it is one of the important quality indexes of silica brick. General requirements below 2.38, high quality silica brick should be less than 2.35. The true density is small, reflecting a large number of scale quartz and square quartz in the brick, the residual quartz is small, so the residual line expansion is small, and the strength is decreased in useThe raw materials for the manufacture of silica brick. The higher the SiO2 content of silica raw material, the higher the refractoriness. The most harmful impurities are Al2O3, K2O, Na2O and so on. They seriously reduce the refractoriness of refractory products. Brick with SiO2 content of not less than 96% of silica as raw materials, adding mineralizer (e.g. millscale, lime) and binder (such as molasses, sulfite pulp waste liquid), after mixing, molding, drying, sintering and other processes in the system.

- Q: What is the main material of silica brickIt's common, the kind we see so often!

- More than 94% silica content. True density 2.35g/cm3. With acid resistance, slag erosion performance.

- Q: The United States of our brick anti-dumping duties?

- At present of our brick anti-dumping rate is 73.10%

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- The content of SiO2 is 98.23% crystalline silica as raw material, with sulfite pulp liquid as binder, millscale and lime as mineralizer, by Jin Hongshi (TiO2) as additive, can improve the rate of thermal conductivity of silica brick for coke oven. When the rutile content is 1.5%, the coefficient of thermal conductivity of silica brick for coke oven is 2.66W/ (m.k).

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

Send your message to us

Silica Brick Reinforced Aluminium Silicate Fire Bricks for Copper Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords