Silica Lime Bricks for Hot Blast Furnace Lightweight Silica Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Shape: | Brick | Material: | Other |

| SiO2 Content (%): | 91 | MgO Content (%): | 0 | CaO Content (%): | 0 |

| Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0 | SiC Content (%): | 0 |

| Model Number: | QG1.2 | Brand Name: | sunrise | size: | any size |

Packaging & Delivery

| Packaging Details: | wooden pallet |

| Delivery Detail: | 2 months |

Specifications

light weight fused silica refractory for hot blast furnace

1)Good acid erosion resistance.

2) High softening point with temp

light weight fused silica refractory for hot blast furnace

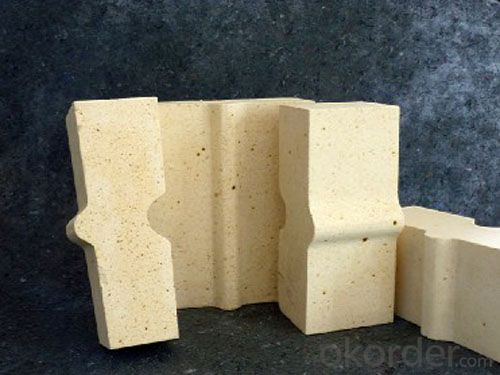

With dense and smooth appearance, uniform corner and edge, pure color and luster and accurate size

1)Good acid erosion resistance.

2) High softening point with temperature.

3) No shrink in burn repeatedly.

Stable Capability, High Quality, Excellent Service, Competitive price is the most important advantage of our products

Item Brand Index | Light weight silica brick |

QG-1.2 | |

SiO2≥ | 91 |

Refractoriness | 1670 |

RUL(0.2 MPa)T1, °C | 1560 |

Apparent Porosity%≤ | ≥45 |

Cold Crushing Strength Mpa ≥ | 3.5 |

True Density g/cm3 ≤ | 2.39 |

Bulk Density g/cm3 ≤ | 1.20 |

Our factory product various kinds of refractory products. The products can be made according with the customers' requirement

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: How much is the highest melting point of silicon?

- . True density 2.35g/cm3. With acid resistance, slag erosion performance. Higher high temperature strength. The softening start temperature is 1620~1670 degrees. Long term use at high temperature without deformation. The thermal shock resistance is low (the heat exchange in water is 1~4 times). The natural silica is used as the raw material, and a proper amount of mineralizer is used to promote the transformation of quartz into quartz in the body. Slowly sintered at 1350~1430 DEG C in the reducing atmosphere. The total volume of heating to 1450 DEG about 1.5~2.2% expansion, the residual expansion will make cutting seam sealing, ensure masonry tightness and good structure strength, so that the brick load softening temperature will reach 1750 degrees Celsius above 1620 degrees in the case of the highest melting point.

- Q: Which material is good for furnace refractory?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick with chromium oxide as its main component has good corrosion resistance, but its thermal shock resistance is poor, and its deformation temperature is lower at high temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, good thermal shock resistance, high strength, resistance to acid and salt corrosion, especially weak acid has good resistance, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: The difference between clay refractory bricks and refractory brick in the application.

- Brick bearing soft temperature and close to the melting point, high temperature strength, can be in high temperature (above 1400 degrees) under the condition of long-term use, but the anti alkali erosion ability, thermal shock stability is the worst, a scrap. The brick is generally used in the coke oven, glass kiln. Other industries basically do not use.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: Such purpose and scope please give me detailed points thank you

- Mainly used for coke oven carbonization chamber and the combustion chamber wall, open hearth furnace regenerator and a sediment chamber, soaking furnace, glass furnace, refractory materials and ceramic brick kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

Send your message to us

Silica Lime Bricks for Hot Blast Furnace Lightweight Silica Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords